Method for copper tailing soiling in high-cold and high-altitude area

A copper tailings, high-altitude technology, applied in the direction of soil preparation methods, soil lifting machinery, gardening methods, etc., can solve the problems of complex production process, complex process, high cost, etc., and achieve the solution of insufficient heat, simple operation, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

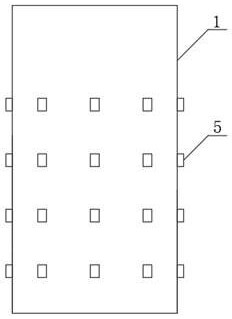

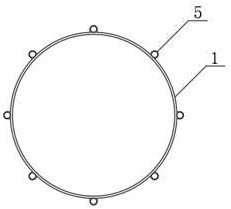

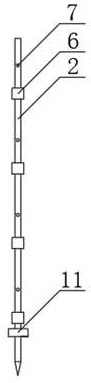

[0039] The present invention realizes the working principle and working process of the preparation device for the preparation method of the fermented mixture: first, the soil layer of the fermentation site is compacted and leveled, and then the fermentation bag 1 is positioned on the site according to the size of the fermentation bag. The tables 10 are installed together, and then insert the lower rod into the positioning point to fix the insertion table 10; then place the fermentation bag 1 on the ground, and pass the upper rod of the vertical support rod 2 through the elastic sleeve 5, which can expand the elastic sleeve. 5, in order to pass through the card slot 6; then install the elastic sleeve clamping rod 8, so that the elastic sleeve 5 is stuck, preventing the elastic sleeve 5 and the fermentation bag 1 from slipping off, and at the same time, the fermentation bag 1 is initially held up; then the fermentation bag 1 Stand up, and at the same time insert the lower end of ...

Embodiment 1

[0050] The method for soilization of copper tailings in alpine and high-altitude areas includes the following steps:

[0051] S1. Sieve the copper tailings, and lay the sieve material on the ground;

[0052] S2, spread the fermentation mixture again, and then plough;

[0053] S3, and then cover the soil, and at the same time, apply a water-retaining agent;

[0054] S4, and then spread the plant ash;

[0055] S5, then plant green manure plants;

[0056] S6, and then spread sawdust on the planting ground.

Embodiment 2

[0058] The method for soilization of copper tailings in alpine and high-altitude areas includes the following steps:

[0059] S1. Sieve the copper tailings, and lay the sieve material on the ground;

[0060] S2, then spread the fermentation mixture, and then plough, the fermentation mixture includes the following raw materials by weight: 32 parts of tailing powder, 12 parts of livestock manure, 2 parts of livestock and poultry urine, 24 parts of plant waste, and 4 parts of coal ash, Wherein the tailings powder is the sieved material after the copper tailings are screened in step S1;

[0061] S3, and then cover the soil, and at the same time, apply a water-retaining agent;

[0062] S4, and then spread the plant ash;

[0063] S5, then plant green manure plants;

[0064] S6, and then spread sawdust on the planting ground.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com