Aperture gradient porous scaffold and minimal curved surface structure unit for same

A curved surface structure and gradient porous technology, applied in the field of biomedical implant materials, can solve the problems of shortened scaffold life, small surface area, unfavorable cell adhesion, etc., to improve biological performance, accelerate tissue regeneration, and improve biocompatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0092] The invention also discloses a method for preparing a porous scaffold with gradient pore size. The preparation method specifically includes the following steps:

[0093] S1, Constructing the structure expression: According to the required structure and performance characteristics of the implant, determine the shape and size parameters of the scaffold, as well as the type, porosity, and size range of the structural units with minimal curved surfaces that need to be selected. Expressions for porous scaffolds with gradient pore sizes;

[0094] S2, constructing the gradient structure: input the expression of the pore-diameter gradient porous scaffold into MATHEMATICA software for visualization processing, and obtain and export the 3D model of the pore-diameter gradient porous scaffold structure based on the minimal surface;

[0095] S3, through the rapid prototyping auxiliary software Materialize Magics, the model of the pore-diameter gradient porous scaffold is layered and...

Embodiment 1

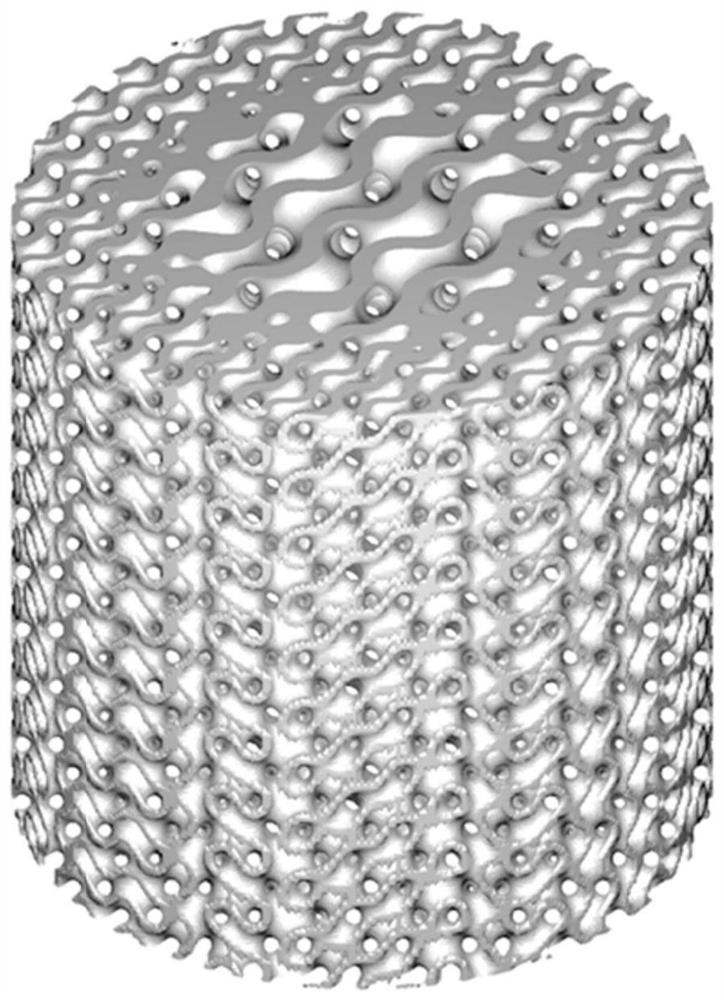

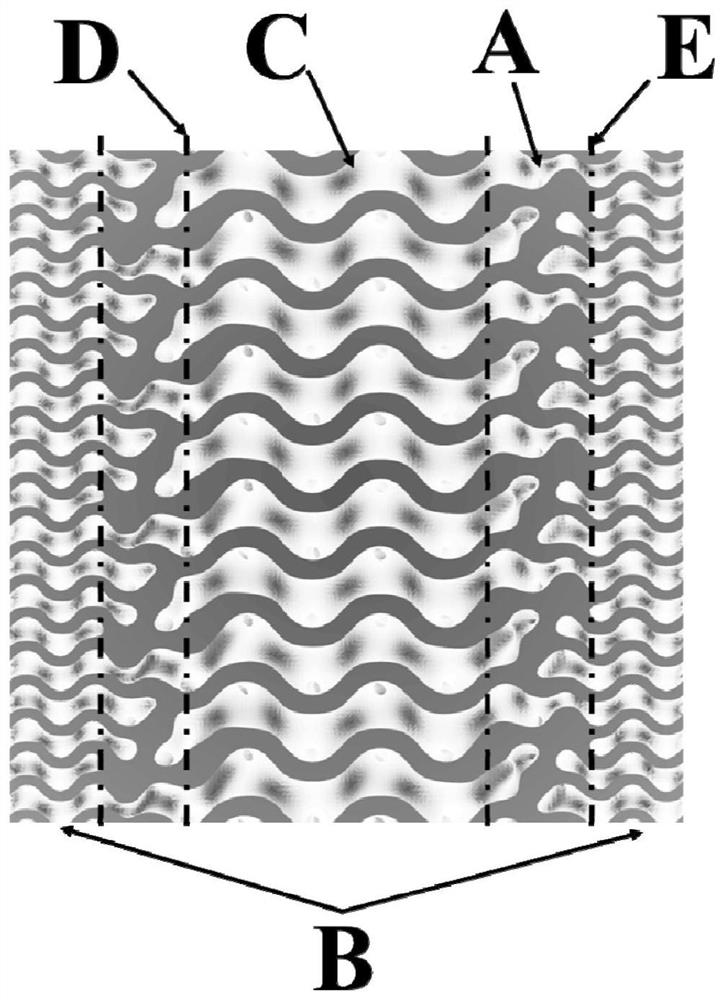

[0103] A pore size gradient porous scaffold based on the Gyroid surface structure unit, the scaffold structure is a columnar porous structure with a size of The porosity is 60%, including the inner scaffold structure 1 and the outer scaffold structure 2; the inner scaffold structure 1 has a larger pore size, which is conducive to the transportation of nutrients, promotes cell proliferation and differentiation, and accelerates tissue regeneration; the outer layer The pore size of the scaffold structure 2 is small, which is conducive to cell adhesion. Specifically, the inner support structure 1 is composed of multiple Gyroid surface structural units with a porosity of 60% and a structural unit size of 2mm. The Gyroid surface structural unit is expressed by the implicit function expression The control is obtained; the outer support structure 2 is composed of multiple Gyroid surface structural units with a porosity of 60% and a structural unit size of 1mm. The Gyroid surface str...

Embodiment 4

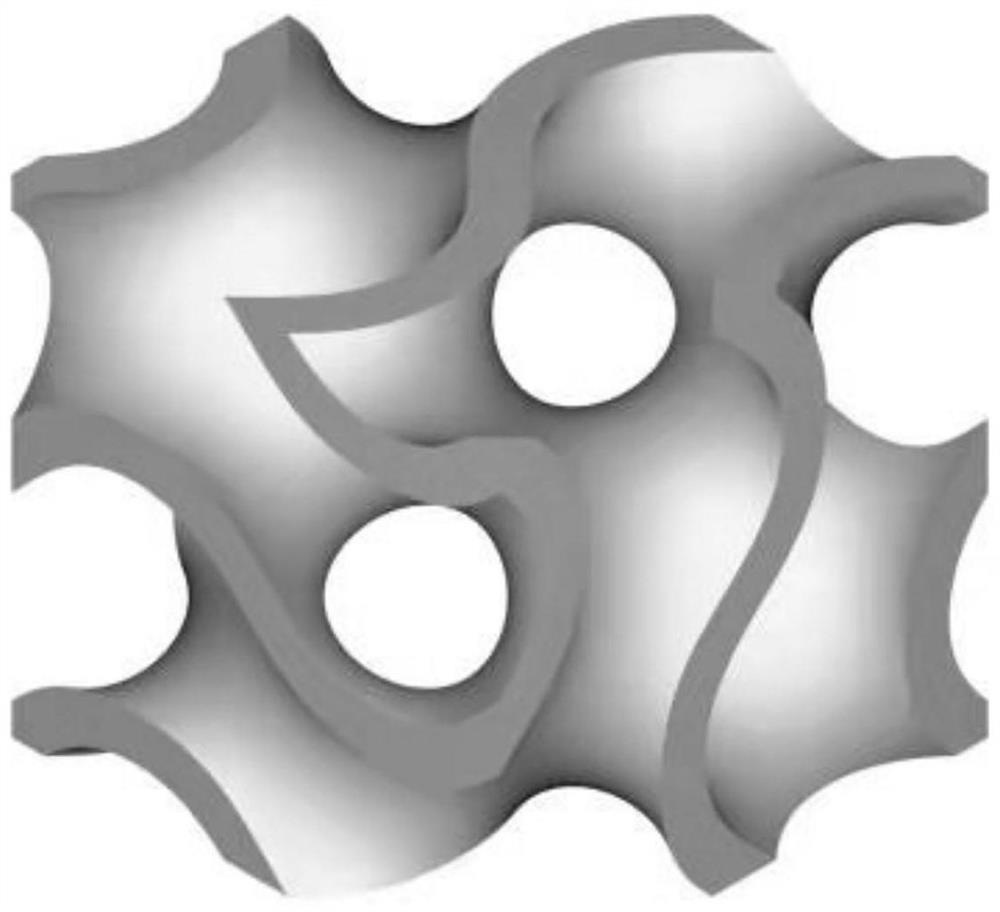

[0117] A pore size gradient porous scaffold based on Primitive curved surface structural units, the pore size gradient porous scaffold is a columnar porous structure with a size of The porosity is 50%, including the inner scaffold structure 1 and the outer scaffold structure 2; the inner scaffold structure 1 has a larger pore size, which is conducive to the transportation of nutrients, promotes cell proliferation and differentiation, and accelerates tissue regeneration; the outer layer The pore size of the scaffold structure 2 is small, which is conducive to cell adhesion. Specifically, the inner support structure 1 is composed of a plurality of Primitive surface structural units with a porosity of 50% and a structural unit size of 2mm. The Primitive surface structural unit is expressed by an implicit function According to the control, the outer support structure 2 is composed of multiple Primitive surface structural units with a porosity of 50% and a structural unit size of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com