A double-layer core-shell structure thermite and preparation method thereof

A core-shell structure and thermite technology, which is applied to attack equipment, explosives processing equipment, explosives, etc., can solve the problems of easy agglomeration of thermite particles, poor combustion performance, low energy release efficiency, etc., and improve thermal reaction performance. , Improve the mechanical strength, the effect of mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

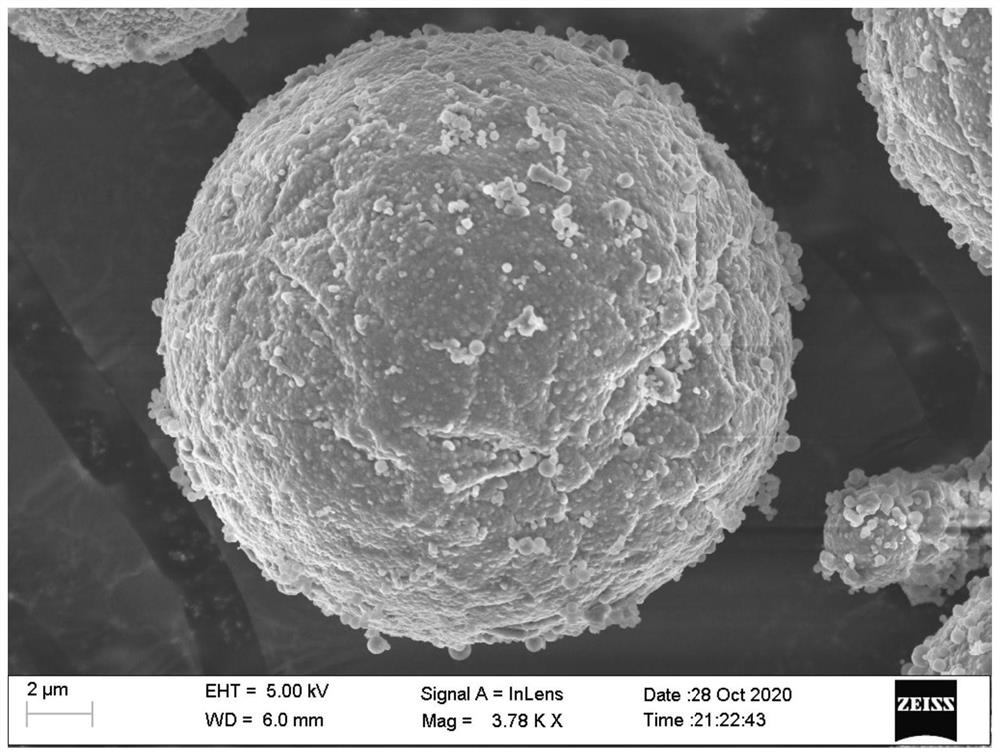

[0046] The present invention proposes a thermite with a novel structure, which has a double-layer core-shell structure. The preparation method of the double-layer core-shell structure thermite of the present invention specifically comprises the following steps:

[0047] Step 1: Add micron-sized aluminum powder into N,N-dimethylformamide, mix evenly, add acid solution, stir and react at room temperature for 30-60 minutes, and obtain Al powder dispersion.

[0048] Among them, the acid solution is H 2 SO 4 solution, HCl solution or HNO 3 solution, the mass fraction of the acid solution is 2%-5%; the particle size of the aluminum powder is 5-20 μm.

[0049] Step 2, dissolving PVDF (polyvinylidene fluoride) in N,N-dimethylformamide (DMF) to obtain a PVDF solution. Preferably in the present invention, the concentration of the PVDF solution is 7-10 g / L. Heat the Al powder dispersion in step 1 to 55-60°C, add PVDF solution, and react at this temperature for 3-6 hours to obtain th...

Embodiment 1

[0058] 1) Surface treatment of Al powder:

[0059] Weigh 30g concentrated H 2 SO 4 Slowly add 1L of distilled water under stirring condition to make it completely dissolved to obtain about 3% H 2 SO 4 solution; weigh 100g of aluminum powder and add it to 1LDMF solvent, and stir after ultrasonication for 5 minutes to make it evenly dispersed in the solvent; mix the prepared 3% H 2 SO 4 The solution was poured into the Al powder dispersion, placed in a fume hood and stirred for 30 minutes.

[0060] 2) Synthesis of Al / PVDF:

[0061] Weigh 6g of PVDF into 1L of DMF solvent, heat the oil bath to 50°C, and stir at this temperature until completely dissolved to obtain a PVDF solution with a concentration of 6g / L. Heating in a water bath to 60°C, adding the prepared PVDF solution into the above-mentioned Al powder pretreatment system at a rate of 17mL / min, and reacting at this temperature for 4 hours; after the reaction, naturally cool to room temperature, collect by suction fil...

Embodiment 2

[0072] The difference between this embodiment and embodiment 1 is that the heating temperature in step 3) is 280°C.

[0073] According to the morphology diagram of the obtained product, the morphology of the product synthesized in this example is similar to the morphology of the product in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com