Covalent organic framework material with respiratory effect as well as preparation method and application thereof

A technology of covalent organic framework and breathing effect, applied in the direction of separation methods, analytical materials, chemical instruments and methods, etc., can solve the problems of increasing the growth of crystal framework defects, loss of crystallinity, collapse, etc., achieving low cost and easy operation , High stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A covalent organic framework material with breathing effect, the preparation method of which comprises the steps of:

[0034] (1) Place 49.2mg (0.08mmol) TFMB (substituent R=H) and 30.4mg (0.08mmol) TAPM in an ampoule, add a mixture of 2.8mL mesitylene and 1.2mL chloroform, and ultrasonically disperse It is well mixed;

[0035] (2) Add 0.4mL of acetic acid solution (12mol / L) to the ampoule, then freeze the ampoule with liquid nitrogen, vacuumize, and seal the ampoule under vacuum conditions;

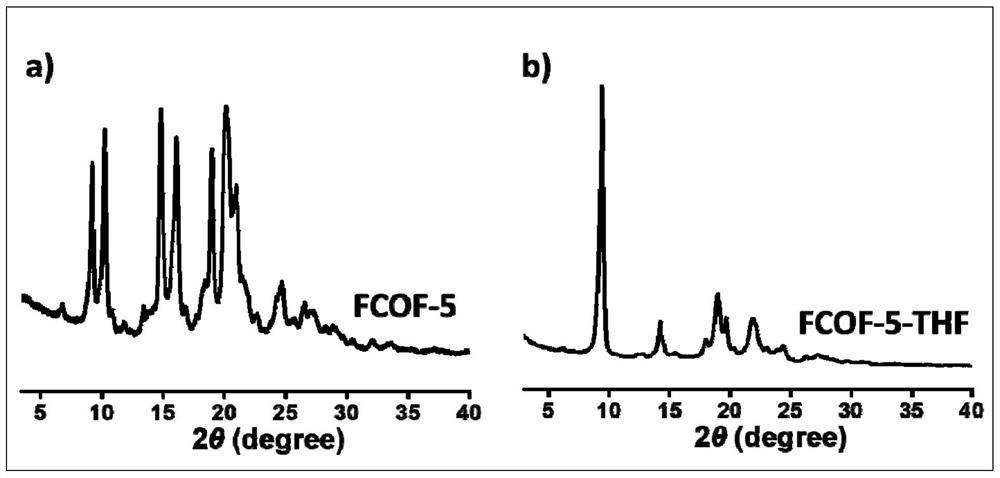

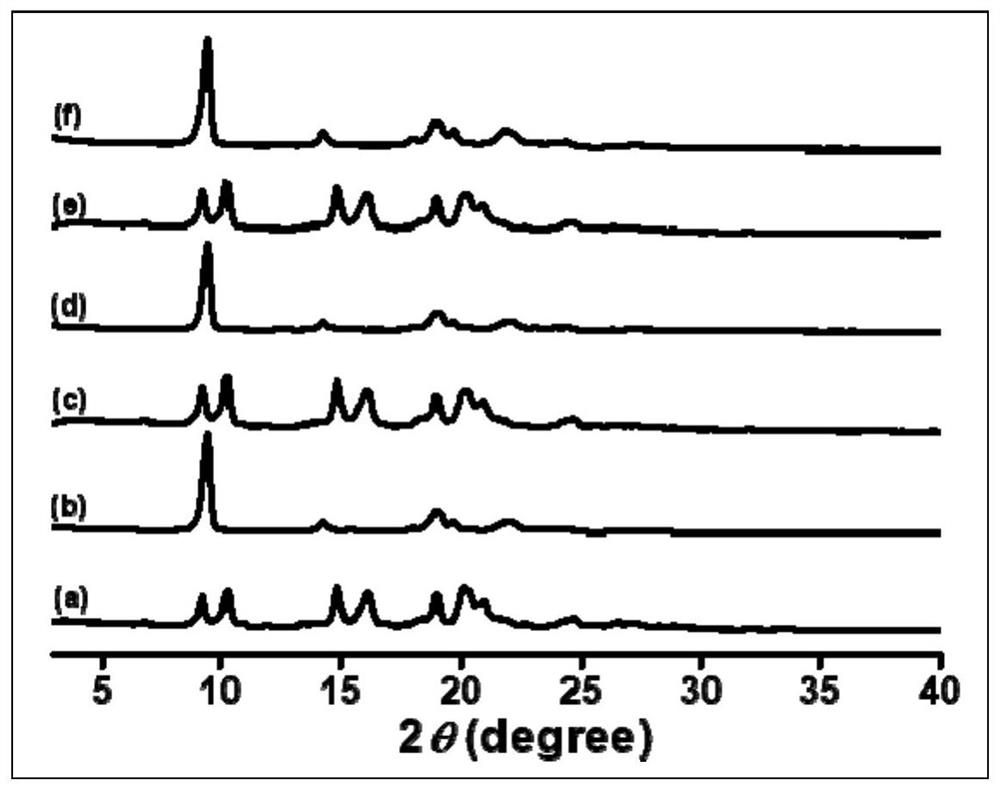

[0036] (3) Raise the temperature of the reaction system and fully react for 168 hours at 110° C. (the crystallinity of the product is the best when tested by XRD);

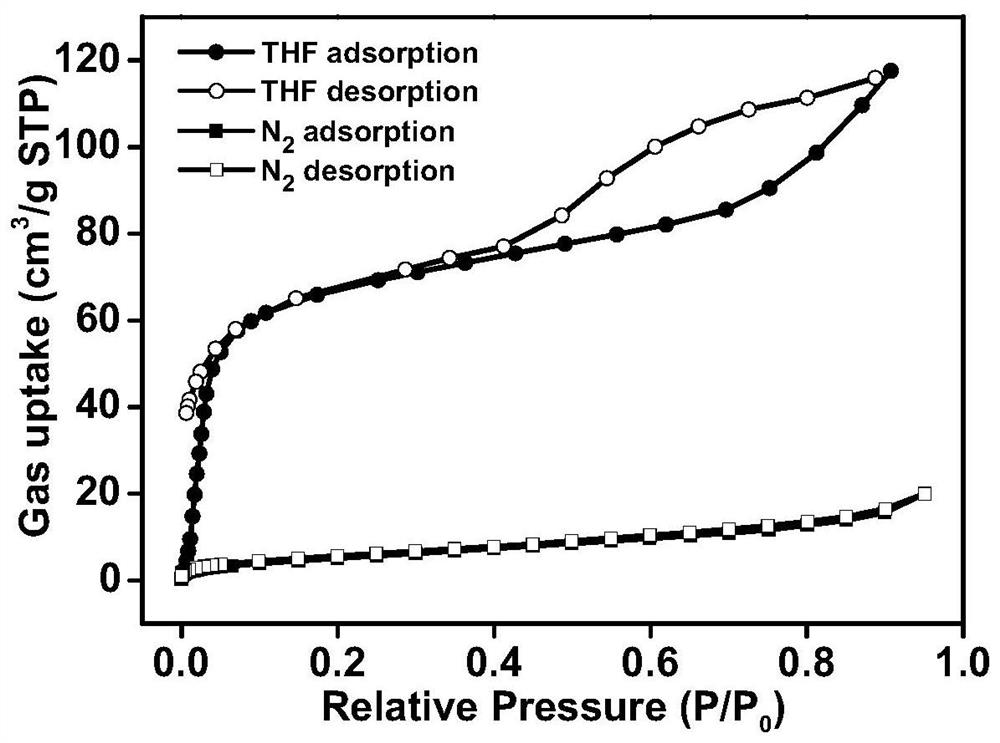

[0037] (4) After the reaction is completed, cool down to room temperature and obtain powder by suction filtration. After the powder is washed with tetrahydrofuran and dichloromethane in sequence, it is extracted with tetrahydrofuran, methanol, dichloromethane and acetone in order by Soxhlet, and then vacuum-dried to ...

Embodiment 2

[0047] The covalent organic framework@polyvinylidene fluoride membrane was prepared by using the FCOF-5 prepared in Example 1 as a raw material. The specific preparation method is as follows:

[0048] (1) After fully pulverizing 40 mg of the covalent organic framework material powder prepared in Example 1, mix evenly with a solution obtained by dissolving 40 mg of polyvinylidene fluoride in 0.5 mL of N,N-dimethylformamide;

[0049] (2) Apply a mixture of the obtained covalent organic framework material and polyvinylidene fluoride (number average molecular weight 534,000) evenly on a glass sheet with a scraper, and bake in an oven at 120°C for 4 hours to remove the solvent;

[0050] (3) Take out the above-mentioned glass sheet, after cooling to room temperature, immerse in ethanol to release the mold, and dry it in an oven at 80°C to obtain a curly covalent organic framework@polyvinylidene fluoride film.

[0051] Cut the above-mentioned covalent organic framework@polyvinylidene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com