Method for preparing metal alloy powder through magnesiothermic reduction

A metal alloy and powder technology, applied in the field of metal alloy powder preparation, can solve problems such as the discussion of oxygen content of metal alloys, and achieve the effects of shortening reduction time, saving energy consumption, and improving reduction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

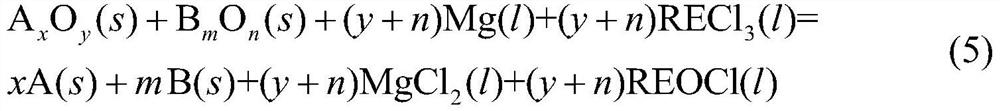

Method used

Image

Examples

example 1

[0055] Step 1, prepare 50g Mg-MgCl 2 -KCl-HoCl 3 Mixed molten salt, where, HoCl 3 The mass is 14.4g, and the mass of Mg is 2.2g.

[0056] Step 2, put 1g TiO 2 powder ((≥98%, anatase type) and 1g V 2 o 5 The powder was compressed into small pieces with a diameter of 4 mm and a thickness of 1 mm under a pressure of 650 MPa, and then sintered at 1000 °C for 25 h. Put the sintered chips and mixed molten salt into a titanium crucible (35mm outer diameter, 2mm thickness, 95mm height), cover the titanium lid, and then put it into a stainless steel crucible (stainless steel crucible size: outer diameter 120mm, thickness 3mm, height 110- 120mm), and place 40g titanium sponge and 8g magnesium ingot around the titanium crucible (between the titanium crucible and the stainless steel crucible). Then weld and seal the stainless steel crucible and put it into a muffle furnace, set the temperature at 850° C., and reduce the reaction time for 5 hours.

[0057] Step 3, after taking the s...

example 2

[0059] Step 1, prepare 50g Mg-MgCl 2 -KCl-HoCl 3 Mixed molten salt, where, HoCl 3 The mass is 14.4g, and the mass of Mg is 2.2g.

[0060] Step 2, put 1g TiO 2 powder ((≥98%, anatase type) and 1g V 2 o 5 The powder was compressed into small pieces with a diameter of 4 mm and a thickness of 1 mm under a pressure of 650 MPa, and then sintered at 1000 °C for 25 h. Put the sintered chips and mixed molten salt into a titanium crucible (35mm outer diameter, 2mm thickness, 95mm height), cover the titanium lid, and then put it into a stainless steel crucible (stainless steel crucible size: outer diameter 120mm, thickness 3mm, height 110- 120mm), and place 40g of titanium sponge and 8g of magnesium ingot around the titanium crucible. Then weld and seal the stainless steel crucible and put it into a muffle furnace, set the temperature at 850° C., and reduce the reaction time for 15 hours.

[0061] Step 3, after taking the stainless steel crucible out of the furnace, put it into wa...

example 3

[0063] Step 1, prepare 50g Mg-MgCl 2 -KCl-HoCl 3 Mixed molten salt, where, HoCl 3 The mass is 14.4g, and the mass of Mg is 2.2g.

[0064] Step 2, put 1g TiO 2 Powder (≥98%, anatase type), 1g V 2 o 5The powder and 0.1 g of calcium carbonate were pressed into small pieces with a diameter of 4 mm and a thickness of 1 mm under a pressure of 650 MPa, and then sintered at 1000 ° C for 25 h. Put the sintered flakes and mixed molten salt into a titanium crucible (35mm outer diameter, 2mm thickness, 95mm height), cover the titanium cover, and then put it into a stainless steel crucible (place 40g titanium sponge and 8g magnesium ingot around the titanium crucible) (Stainless steel crucible size: outer diameter 120mm, thickness 3mm, height 110-120mm). Then put the stainless steel crucible into the muffle furnace, set the temperature at 850°C, and reduce the reaction time for 5h.

[0065] Step 3, after taking the stainless steel crucible out of the furnace, put it into water for r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| oxygen content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com