Photosensitive resin/beta-tricalcium phosphate composite biological ink capable of being used for DLP printing and preparation method of photosensitive resin/beta-tricalcium phosphate composite biological ink

A technology of photosensitive resin and tricalcium phosphate, which is applied in the direction of additive manufacturing, manufacturing tools, tissue regeneration, etc., can solve the problems of slow degradation rate of bone repair materials at sintering temperature, difficulty in controlling the shape and size of pores, and poor pore connectivity. High material utilization rate, fast molding speed, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

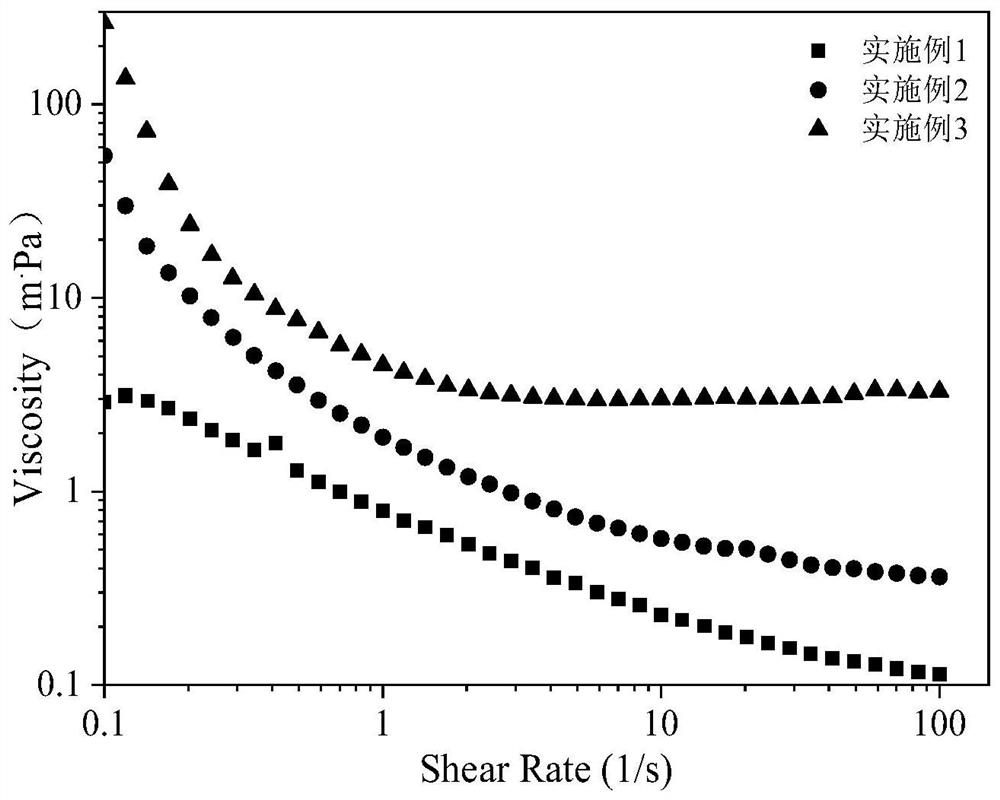

[0034] (1) Add β-tricalcium phosphate powder to 90% ethanol solution of KH550 for modification (mass volume ratio is 10%), and the addition ratio of silane coupling agent is 1wt% of β-tricalcium phosphate ceramic powder , Reaction at 75°C for 6 hours, ball milling after drying.

[0035] (2) Weigh 25g of polyethylene glycol diacrylate, 5g of PEGDMA, and 0.15g of BAPO, mix them by magnetic stirring for 30 minutes, and let stand for 1 day to obtain a photosensitive resin system.

[0036] (3) 20.2 g of modified β-tricalcium phosphate ceramic powder was added in batches to the photosensitive resin system, and ultrasonically dispersed to obtain a ceramic slurry.

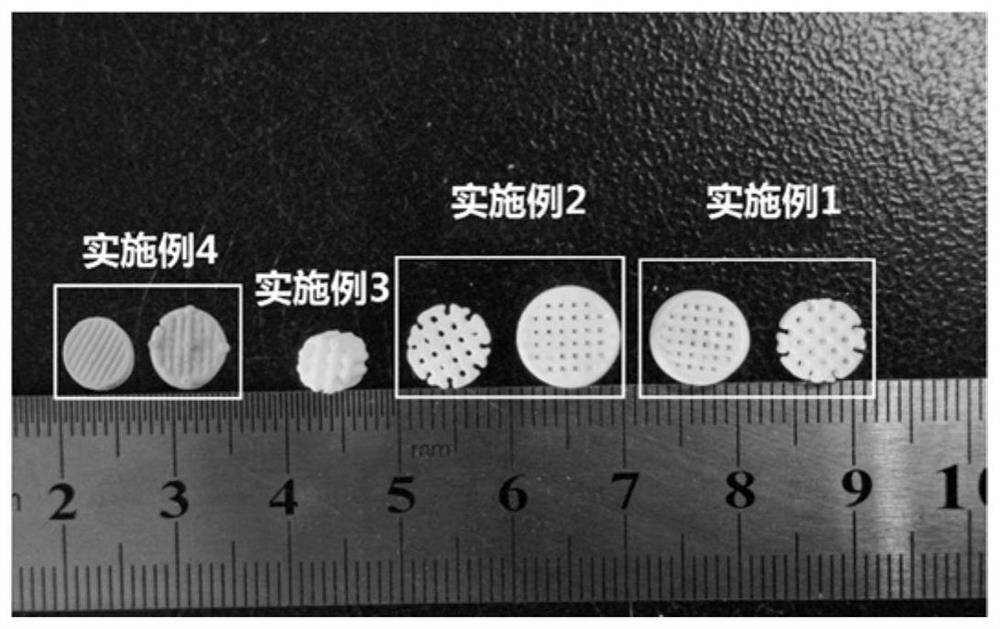

[0037] (4) Add the ceramic slurry into the trough of the light-curing printer, adjust the exposure time to 1.3s, open the sliced bracket model file, and print the bracket blank.

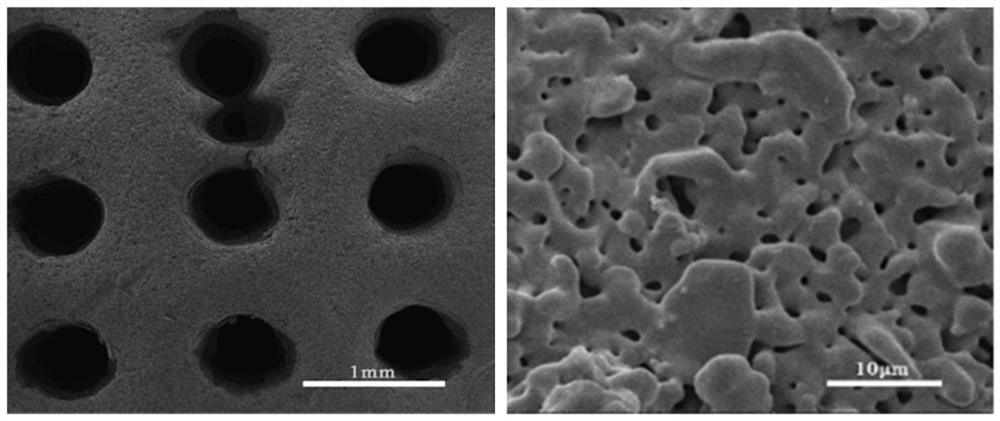

[0038] (5) The green body is dried, degreased, and sintered at high temperature to obtain the bracket. The sintering route is: 0.5°C / min fro...

Embodiment 2

[0040] (1) Add β-tricalcium phosphate powder to 90% ethanol solution of KH550 for modification (mass volume ratio is 10%), and the addition ratio of silane coupling agent is 2wt% of β-tricalcium phosphate ceramic powder , Reaction at 85°C for 5 hours, ball milling after drying.

[0041] (2) Weigh 23g of polyethylene glycol diacrylate, 2g of HDDA, 5g of PEGDMA, and 0.45g of BAPO, mix them by magnetic stirring for 30 minutes, and let stand for 1 day to obtain a photosensitive resin system.

[0042] (3) 30.4 g of modified tricalcium phosphate ceramic powder was added in batches to the photosensitive resin system, and ultrasonically dispersed to obtain a ceramic slurry.

[0043] (4) Add the ceramic slurry into the trough of the light-curing printer, adjust the exposure time to 1.4s, open the sliced bracket model file, and print the bracket blank.

[0044] (5) The green body is dried, degreased, and sintered at high temperature to obtain the bracket. The sintering route is: 0.8...

Embodiment 3

[0046] (1) Add β-tricalcium phosphate powder to 90% ethanol solution of KH570 for modification (mass volume ratio is 10%), and the addition ratio of silane coupling agent is 4wt% of β-tricalcium phosphate ceramic powder , Reaction at 75°C for 6 hours, ball milling after drying.

[0047] (2) Weigh 22.4g of polyethylene glycol diacrylate, 2.6g of HDDA, 5g of CEA, and 0.45g of BAPO, mix them by magnetic stirring for 30 minutes, and let them stand for 1 day to obtain a photosensitive resin system.

[0048] (3) 45.4 g of modified tricalcium phosphate ceramic powder was added in batches to the photosensitive resin system, and ultrasonically dispersed to obtain a ceramic slurry.

[0049](4) Add the ceramic slurry into the trough of the light-curing printer, adjust the exposure time for 1.5s, open the sliced bracket model file, and print the bracket blank.

[0050] (5) The green body is dried, degreased, and sintered at high temperature to obtain the bracket. The sintering route i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com