Syringin imprinted monolithic column preparation method

A technology of syringin and monolithic column, which is applied in the field of preparation of syringin imprinted monolithic column, can solve the problems of complex operation, cumbersome preparation process, and low purity, and achieve the effect of simple synthesis process, good MIPs performance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Preparation of syringin imprinted monolithic column by in situ polymerization:

[0022] a. heating choline chloride and itaconic acid in a molar ratio of 1.5:1 in an oil bath at a temperature of 90°C for 60 minutes to obtain choline chloride-itaconic acid;

[0023] b. Dissolve 1.14% of syringin and 4.80% of choline chloride-itaconic acid obtained in step a in 12.05% of methanol, then add 0.46% of azobisisobutyronitrile, and then add dimethacrylic acid Ethylene glycol ester 21.84%, 1-butyl-3-methylimidazolium tetrafluoroborate 54.09%, isopropanol 2.38% and polyethylene glycol 400 3.25%, sonicate for 30 minutes to dissolve all components and mix well , to obtain a homogeneous solution, and then flush nitrogen in the solution to remove dissolved oxygen. After the solution is clarified, transfer the solution to a stainless steel column, quickly seal both ends of the stainless steel column, and react in a water bath at a temperature of 60°C 12 hours;

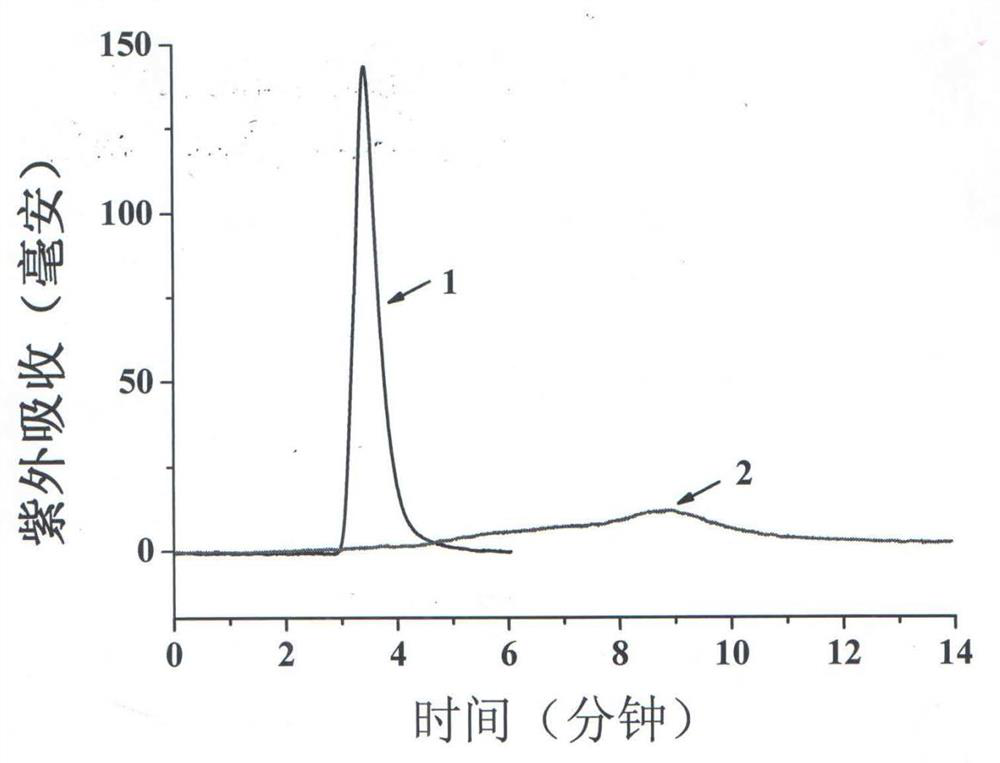

[0024] c. Take the s...

Embodiment 2

[0027] Preparation of syringin imprinted monolithic column by in situ polymerization:

[0028] a. heating choline chloride and itaconic acid in a molar ratio of 1.5:1 in an oil bath at a temperature of 90°C for 60 minutes to obtain choline chloride-itaconic acid;

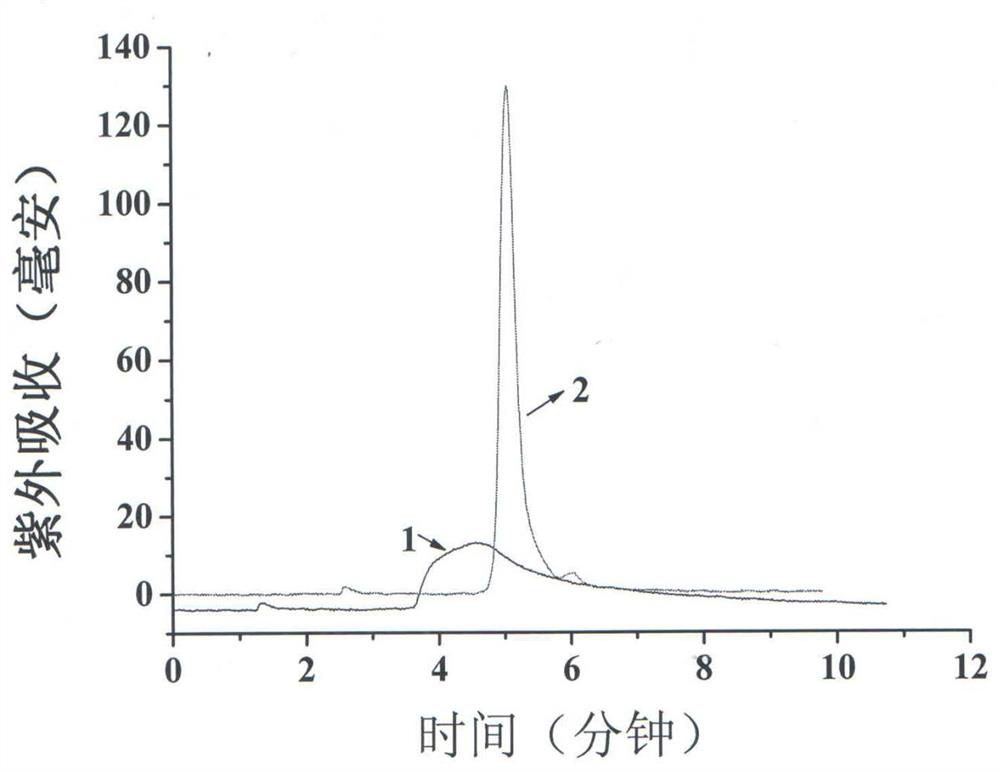

[0029] b. Dissolve 0.50% of syringin and 4.84% of choline chloride-itaconic acid obtained in step a in 12.13% of methanol, then add 0.46% of azobisisobutyronitrile, and then add dimethacrylic acid Ethylene glycol ester 21.96%, 1-butyl-3-methylimidazolium tetrafluoroborate 54.44%, isopropanol 2.41% and polyethylene glycol 400 3.26%, sonication for 30min, so that all components are completely dissolved and mixed , to obtain a homogeneous solution, and then flush nitrogen in the solution to remove dissolved oxygen. After the solution is clarified, transfer the solution to a stainless steel column, quickly seal both ends of the stainless steel column, and place it in a water bath at a temperature of 60°C Reaction for 1...

Embodiment 3

[0033] Preparation of syringin imprinted monolithic column by in situ polymerization:

[0034] a. heating choline chloride and itaconic acid in a molar ratio of 1.5:1 in an oil bath at a temperature of 90°C for 60 minutes to obtain choline chloride-itaconic acid;

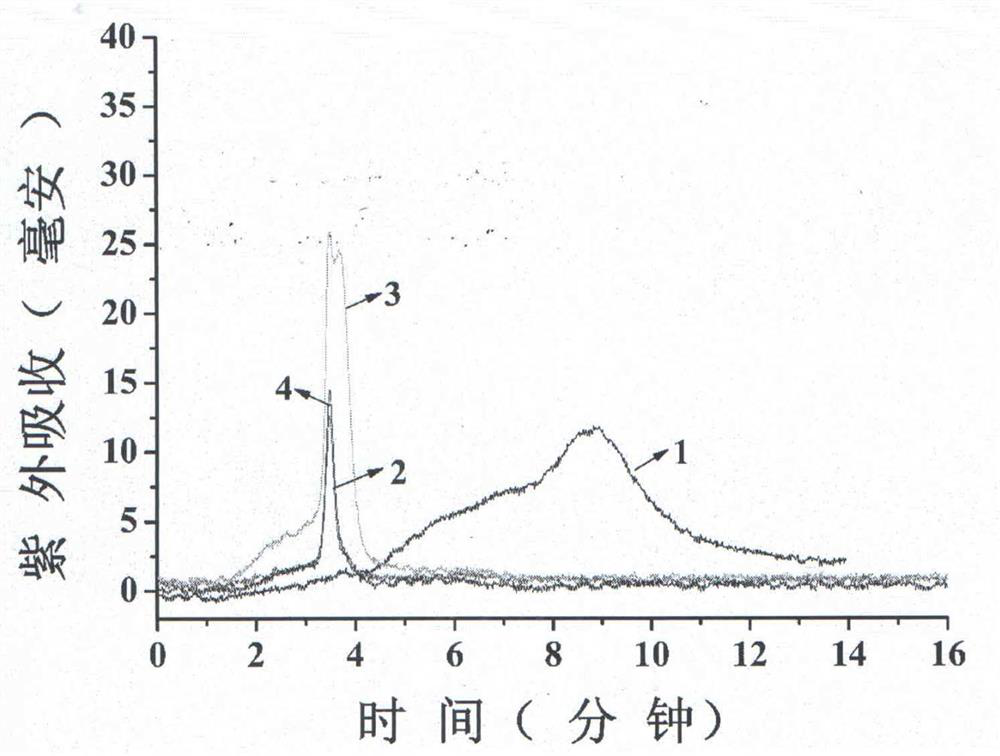

[0035] b. Dissolve 1.18% of syringin and 5.00% of choline chloride-itaconic acid obtained in step a in 12.51% of methanol by mass percentage, then add 0.48% of azobisisobutyronitrile, and then add dimethacrylic acid Ethylene glycol ester 18.83%, 1-butyl-3-methylimidazolium tetrafluoroborate 56.16%, isopropanol 2.49% and polyethylene glycol 400 3.36%, sonication for 30min, so that all components are completely dissolved and mixed , to obtain a homogeneous solution, and then flush nitrogen in the solution to remove dissolved oxygen. After the solution is clarified, transfer the solution to a stainless steel column, quickly seal both ends of the stainless steel column, and place it in a water bath at a temperature of 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com