Water-based polyacrylate antibacterial emulsion, preparation method and application thereof in paint

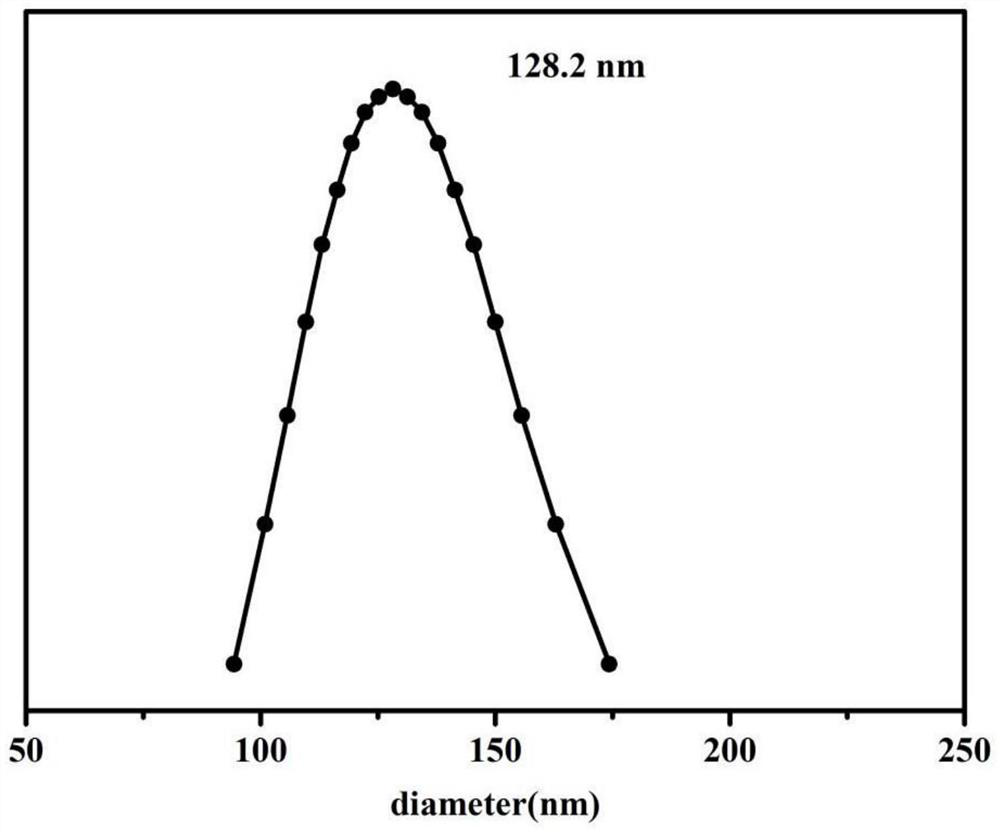

A polyacrylate and acrylate technology, which is applied in the field of water-based polyacrylate antibacterial emulsion and its preparation, can solve the problems of reduction, poor solubility of isothiazolinone derivatives, poor compatibility of water-based emulsions or coatings, and the like. Achieving good mold resistance, reducing dosage, and good particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

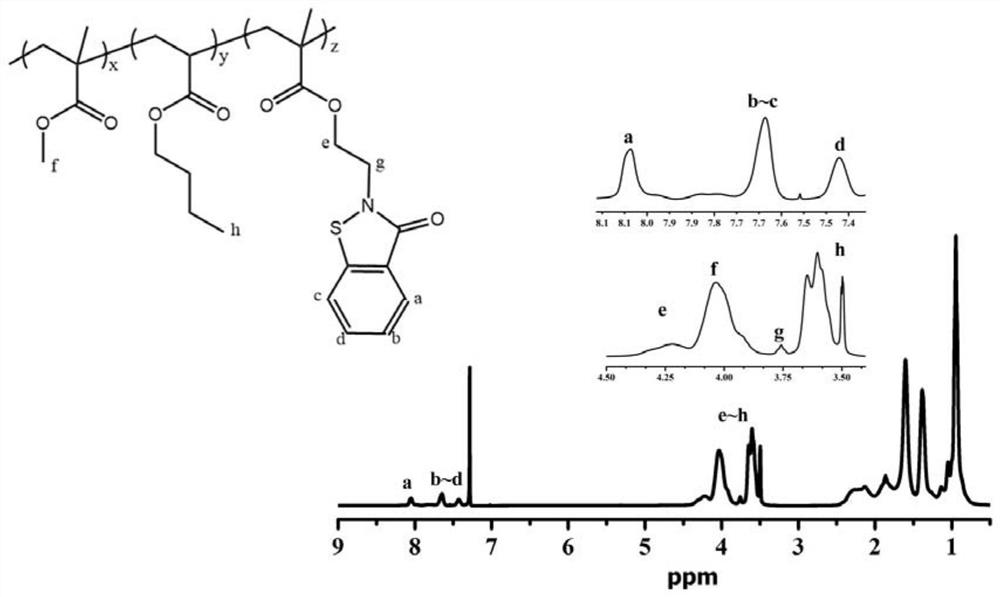

[0040] A kind of water-based polyacrylate antibacterial emulsion (emulsion A), water-based polyacrylate antibacterial emulsion is obtained by following raw material reaction by weight:

[0041]

[0042]

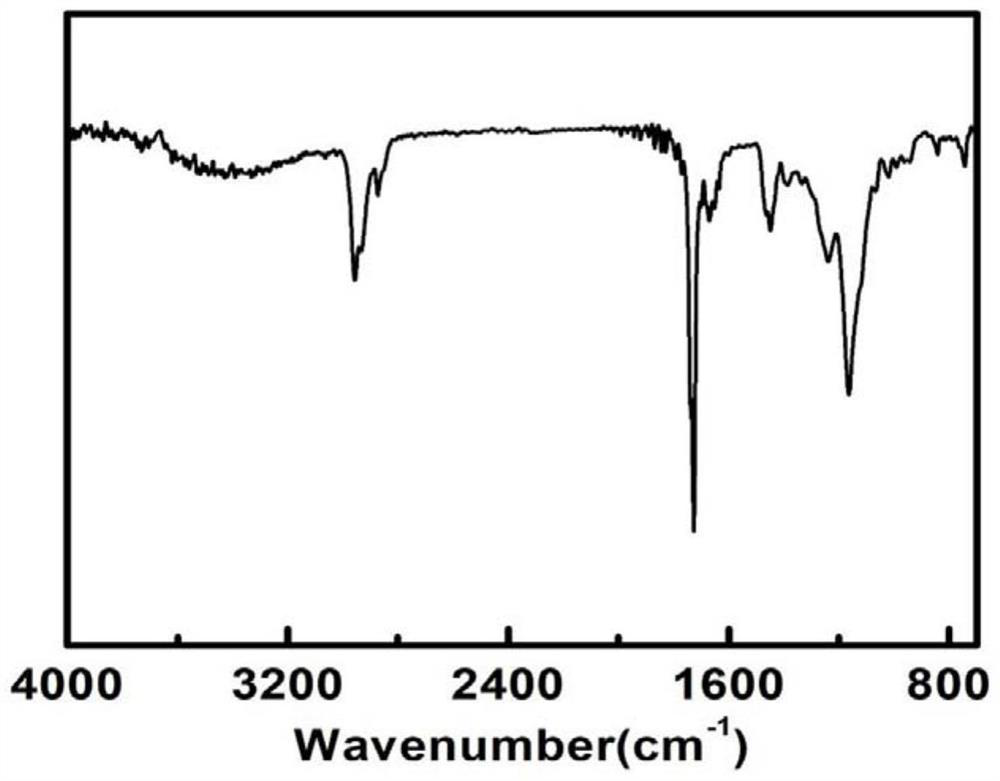

[0043] The preparation of containing isothiazolinone base monomer comprises the following steps:

[0044] a. Add 3.28g of sodium hydroxide, 160mL of water and 10.0g of 1,2-benzisothiazolin-3-one to the flask in sequence, and mix thoroughly to form 1,2-benzisothiazolin-3-one stable sodium salt;

[0045] b. Then add 24.8g of 2-bromoethanol to the sodium salt in step a, reflux the reaction in an oil bath at 80°C for 3h, add dichloromethane to extract after the reaction, dry with anhydrous sodium sulfate, filter and distill to obtain Yellow solid, after dissolving the light yellow solid in 120mL tetrahydrofuran, add 7.35g triethylamine.

[0046] c. Add 7.58g of methacryloyl chloride dropwise to the tetrahydrofuran solution in step b within 1 hour in an ice-water bath, rea...

Embodiment 2

[0072] A kind of water-based polyacrylate antibacterial emulsion (emulsion B), water-based polyacrylate antibacterial emulsion is obtained by following raw material reaction by weight:

[0073]

[0074] The preparation of containing isothiazolinone base monomer comprises the following steps:

[0075] a. Add 3.50g of sodium hydroxide, 150mL of water and 10.0g of 1,2-benzisothiazolin-3-one to the flask in sequence, and mix thoroughly to form 1,2-benzisothiazolin-3-one stable sodium salt;

[0076] b. Then add 25.5g of 2-bromoethanol to the sodium salt in step a, reflux the reaction in an oil bath at 80°C for 3h, add dichloromethane to extract after the reaction, dry with anhydrous sodium sulfate, filter and distill to obtain Yellow solid, after dissolving the light yellow solid in 130mL tetrahydrofuran, add 6.5g triethylamine.

[0077] c. Add 8.50 g of methacryloyl chloride dropwise to the tetrahydrofuran solution in step b within 1 hour in an ice-water bath, react overnight...

Embodiment 3

[0098] A kind of water-based polyacrylate antibacterial emulsion (emulsion C), water-based polyacrylate antibacterial emulsion is obtained by following raw material reaction by weight:

[0099]

[0100] The preparation of containing isothiazolinone base monomer comprises the following steps:

[0101] a. Add 4.0g of sodium hydroxide, 155mL of water and 8.0g of 1,2-benzisothiazolin-3-one to the flask in sequence, and mix thoroughly to form 1,2-benzisothiazolin-3-one stable sodium salt;

[0102] b. Then add 22.5g of 2-bromoethanol to the sodium salt in step a, reflux the reaction in an oil bath at 80°C for 3h, add dichloromethane to extract after the reaction, dry with anhydrous sodium sulfate, filter and distill to obtain Yellow solid, after dissolving the light yellow solid in 130mL tetrahydrofuran, add 8.0g triethylamine.

[0103] c. Add 10.0 g of methacryloyl chloride dropwise to the tetrahydrofuran solution in step b within 1 hour in an ice-water bath, react overnight, fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Effective particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com