Preparation and application of plant fiber-based reinforced carbon fiber network

A plant fiber and carbon fiber technology, applied in the direction of carbon fiber, fiber treatment, fiber chemical characteristics, etc., can solve the problems of poor compression deformation stability and low mechanical strength of carbon airgel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

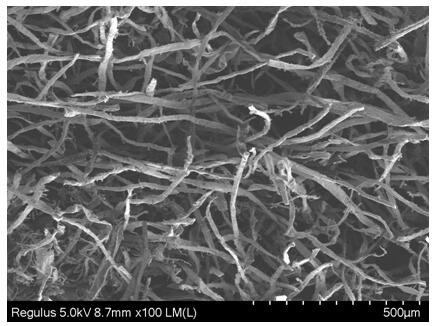

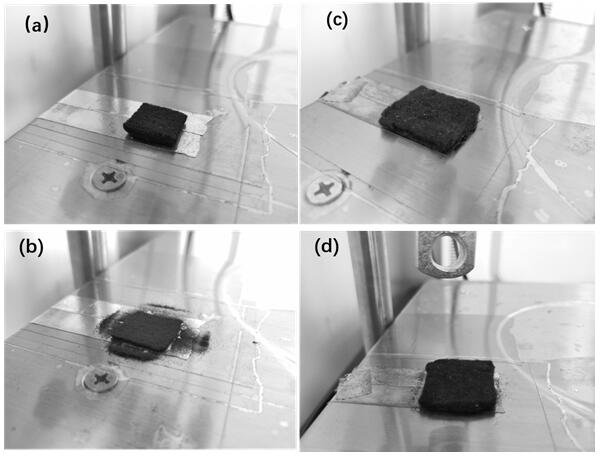

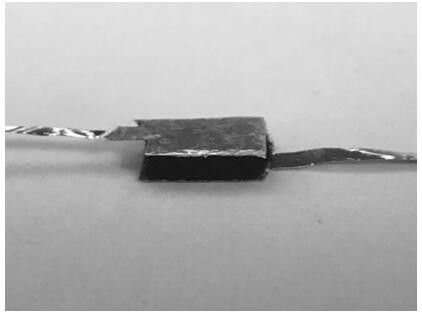

[0021] After shredding the commercial coniferous wood pulp board and soaking it with deionized water overnight, use a fiber disintegrator to decompose at 10,000 rpm, dissolve 5 parts of sodium periodate in 95 parts of deionized water, and configure 100 parts of sodium periodate solution; Take 5 parts of coniferous wood pulp and disperse in the above 100 parts of sodium periodate solution. After the dispersion is uniform, the dispersion system is heated to 40 ° C, reacted for 2 hours, dehydrated, centrifugally washed with deionized water for 3 times, filtered to form, and freeze-dried Finally, a cellulose fiber network with a thickness of about 5 mm was obtained. Place the dried cellulose fiber network in a tube furnace, pass nitrogen gas, and drive the air out of the furnace, then raise the temperature to 300°C at a rate of 2°C / min under the protection of nitrogen, keep it warm for 2 hours, and continue to heat at a temperature of 2°C / min. The temperature was raised to 800°C a...

Embodiment 2

[0024] After shredding the commercial coniferous wood pulp board and soaking it overnight with deionized water, use a fiber disintegrator to decompose at 10,000 rpm, dissolve 5 parts of sodium periodate in 95 parts of deionized water, and configure 100 parts of sodium periodate solution; Take 5 parts of coniferous wood pulp and disperse in the above 100 parts of sodium periodate solution. After the dispersion is uniform, heat the dispersion system to 30°C, react for 3 hours, dehydrate, wash with deionized water for 3 times, filter to form, and freeze-dry Finally, a cellulose fiber network with a thickness of about 5 mm was obtained. Place the dried cellulose fiber network in a tube furnace, ventilate nitrogen, and drive the air out of the furnace, then raise the temperature to 300°C at a rate of 3°C / min under the protection of nitrogen, keep it warm for 2 hours, and continue to heat at a temperature of 3°C / min. The temperature was raised to 800°C at a speed of 1 minute, kept f...

Embodiment 3

[0027] After shredding the commercial coniferous wood pulp board and soaking it with deionized water overnight, use a fiber disintegrator to decompose at 10,000 rpm, dissolve 5 parts of sodium periodate in 95 parts of deionized water, and configure 100 parts of sodium periodate solution; Take 5 parts of coniferous wood pulp and disperse in the above 100 parts of sodium periodate solution. After the dispersion is uniform, the dispersion system is heated to 40 ° C, reacted for 2 hours, dehydrated, centrifugally washed with deionized water for 3 times, filtered to form, and freeze-dried Finally, a cellulose fiber network with a thickness of about 5 mm was obtained. Place the dried cellulose fiber network in a tube furnace, pass nitrogen gas, and drive the air out of the furnace, then raise the temperature to 300°C at a rate of 2°C / min under the protection of nitrogen, keep it warm for 2 hours, and continue to heat at a temperature of 2°C / min. The temperature was raised to 800°C a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com