EUV light source target drop generation device and method

A generation device and light source technology, which is applied in the direction of exposure devices, optics, and optomechanical equipment in the photographic plate-making process, can solve problems such as difficult to obtain droplets, irregular droplet sizes, and clogging, so as to improve energy conversion efficiency and improve use Efficiency and the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

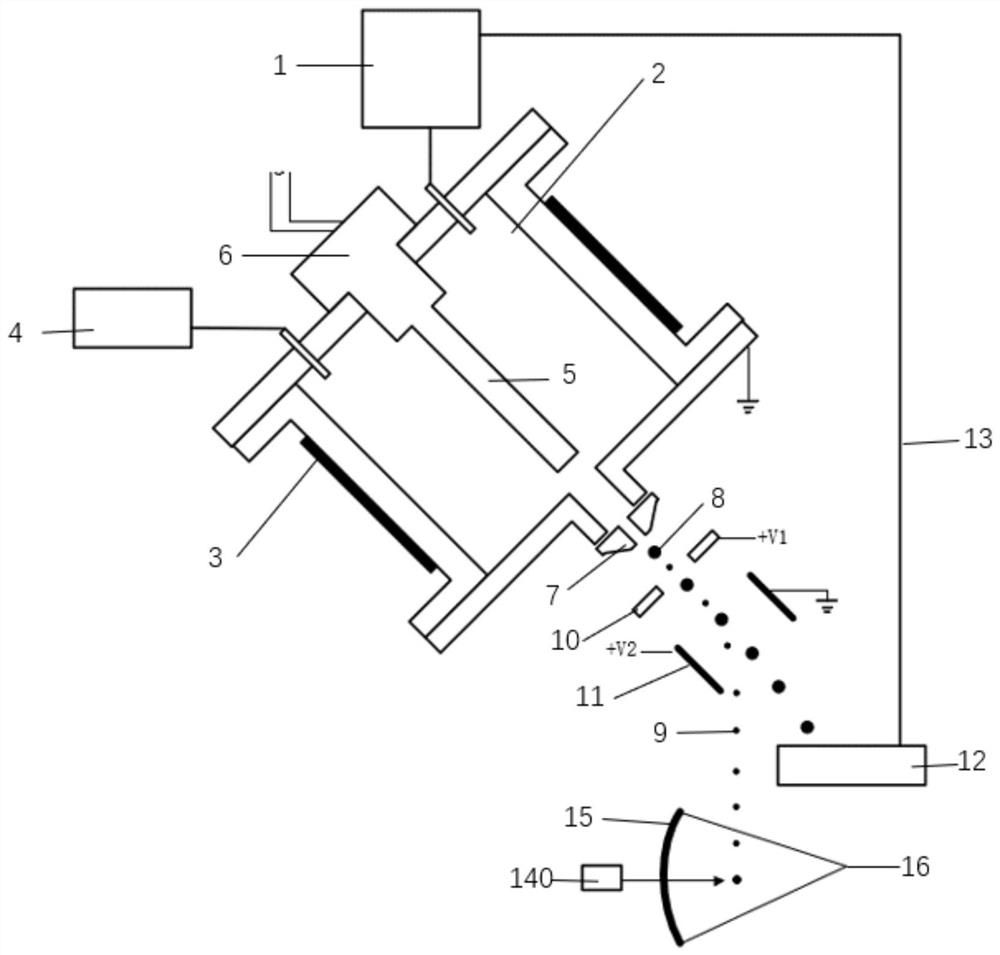

[0023] Such as figure 1 As shown, an EUV light source target droplet generating device includes a droplet generating component, a droplet separation component and a liquid recovery component; the droplet generating component is used to form droplets, and the droplet generating component includes: a storage tank 1 and a chamber 2 , a heating device 3 , a pressure source 4 , a disturbance rod 5 , a piezoelectric excitation module 6 and a microporous nozzle 7 . The storage tank 1 is used to store the material that forms the droplet. The storage tank 1 can store solid or liquid materials. The storage tank 1 can be provided with a heating device to keep the material in a molten state; the material in the storage tank 1 is supplied into the cavity 2. Under the heating effect of the heating device 3 provided on the outer wall of the chamber 2, it melts into a liquid state; the heating device 3 can be arranged inside or outside the chamber, and being arranged outside can avoid contact...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com