A kind of preparation method of defoamer for fermented production of epothilone

A technology for epothilone and antifoaming agent is applied in the field of preparation of antifoaming agent for fermentative production of epothilone, and can solve the problems of reducing the charging coefficient, disturbing fermentation by foam, and not finding epothilone A.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

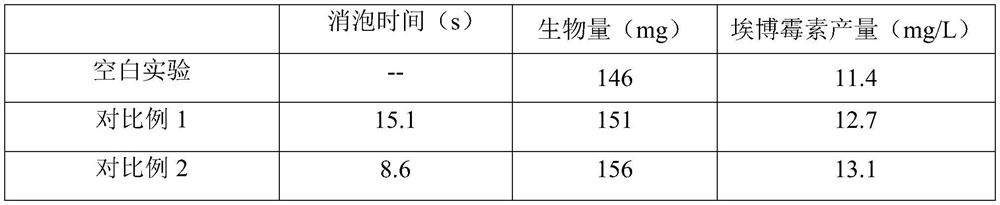

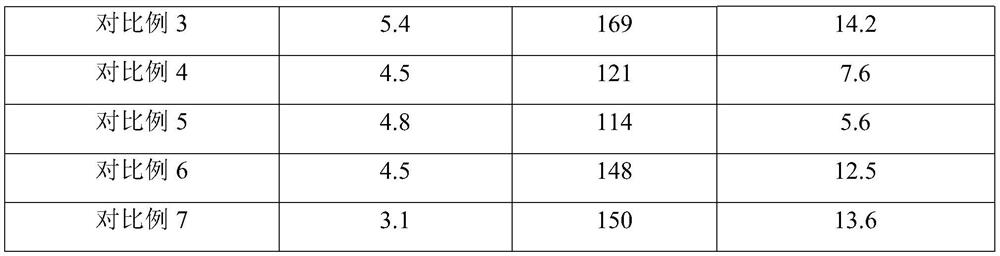

Image

Examples

Embodiment 1

[0026] A kind of preparation method of defoamer for fermented production of epothilone, its concrete scheme is as follows:

[0027] According to the parts by mass, 8g di(ethylene glycol) ethyl ether methacrylate, 55g terminal epoxy silicone oil, 0.8g mercapto-dipolyethylene glycol-tert-butyl propionate and 0.06g 1-methylimidazole hydrochloride Add it to the reaction kettle, the stirring speed is 70r / min, the system temperature is maintained at 120°C, and the reaction is carried out for 2h under the condition of vacuum degree of 0.06MPa under reduced pressure and reflux to obtain di(ethylene glycol) ethyl ether methacrylate modified silicone oil; after completion Add 10g phosphorylated polyether modified amino silicone oil, 18g silicon dioxide, 3g ultrafine aluminum silicate, stir evenly, then heat up to 110°C, the reaction time is 2h, then add 0.6g malonic acid and 0.2g citric acid, The wood plywood board was reacted at a temperature of 80°C for 30min, cooled to 60°C, added 2....

Embodiment 2

[0036] A kind of preparation method of defoamer for fermented production of epothilone, its concrete scheme is as follows:

[0037] According to the parts by mass, 10g of di(ethylene glycol) diethyl ether methacrylate, 58g of terminal epoxy silicone oil, 1.2g of mercapto-dipolyethylene glycol-tert-butyl propionate and 0.1.8g of 1-methylimidazole hydrochloride The salt was added to the reaction kettle, the stirring speed was 80 r / min, the system temperature was maintained at 130 ° C, and the reaction was carried out for 3 h under the condition of vacuum degree of 0.07 MPa under reduced pressure and reflux to obtain di(ethylene glycol) ethyl ether methacrylate modified silicone oil; complete; Then add 14g phosphorylated polyether modified amino silicone oil, 22g silicon dioxide, 5g ultrafine aluminum silicate, stir evenly, then heat up to 130 ℃, the reaction time is 3h, then add 1.2g malonic acid and 0.5g citric acid , the temperature is controlled at 90 ℃, the wood plywood is r...

Embodiment 3

[0046] A kind of preparation method of defoamer for fermented production of epothilone, its concrete scheme is as follows:

[0047] According to the parts by mass, 12g di(ethylene glycol) ethyl ether methacrylate, 68g terminal epoxy silicone oil, 1.6g mercapto-dipolyethylene glycol-tert-butyl propionate and 0.24g 1-methylimidazole hydrochloride Add it to the reaction kettle, the stirring speed is 90r / min, maintain the system temperature at 140°C, and react for 5h under the condition of vacuum degree of 0.09MPa under reduced pressure and reflux to obtain di(ethylene glycol) ethyl ether methacrylate modified silicone oil; after completion Add 18g phosphorylated polyether modified amino silicone oil, 26g silicon dioxide, 8g ultrafine aluminum silicate, stir evenly, then heat up to 140 ° C, the reaction time is 5h, then add 1.8g malonic acid and 0.8g citric acid, The wood plywood board was reacted at a temperature of 110°C for 60min, cooled to 80°C, added 3.6g of surfactant, stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com