Special structural color pigment sheet with good comprehensive performance for automobiles and preparation method thereof

A comprehensive performance and structural color technology, applied in metal material coating process, ion implantation plating, coating, etc., can solve the problem of high production cost of structural color pigment flakes, and achieve improved color stability, hardness and weather resistance , the effect of reducing the preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

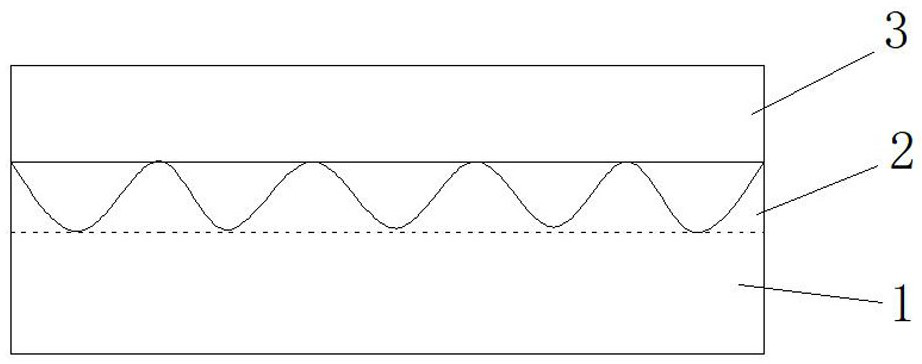

[0030] The present invention also provides a kind of preparation method of the automotive-specific structural color pigment sheet with good comprehensive performance, the steps are as follows (please refer to figure 1 ):

[0031] Step 1. Preparation of nano-scale mirror stainless steel base material

[0032] Using stainless steel as the target material, the stainless steel target is vaporized by high-energy electron beams under vacuum conditions by sputtering coating method, and the vaporized stainless steel is deposited on the substrate to form a layer of nanometer-thick mirror stainless steel substrate . The stainless steel substrate has bright surface, good metallic luster and brightness, high hardness, high temperature resistance, good chemical resistance and storage stability. The thickness of the stainless steel substrate is 50-500nm.

[0033] Step 2. Laser surface engraving

[0034] A femtosecond laser is used to engrave the surface of the above-mentioned mirror sta...

Embodiment 1

[0047] Such as figure 1 As shown, using vacuum coating equipment, using 304 stainless steel as a target material, a mirror-surface 304 stainless steel film layer with a thickness of 50nm is evaporated on the substrate by vacuum sputtering coating method, that is, a mirror-surface 304 stainless steel substrate is obtained.

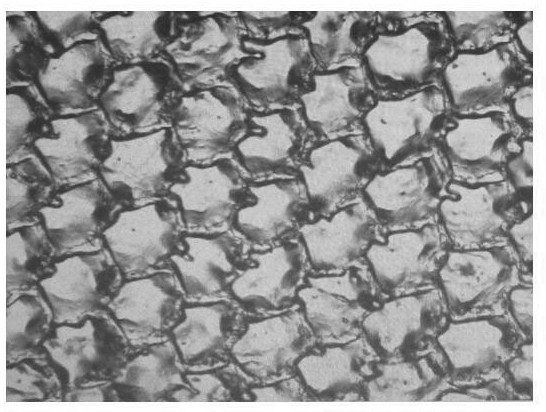

[0048] A femtosecond laser is used to perform laser engraving on the thin film layer of the deposited mirror surface 304 stainless steel substrate to prepare a laser active layer. The single pulse energy of the laser is 0.025mJ, the distance of the abscissa of the laser light is 0.42 microns, and the distance of the ordinate of the laser light is 2 microns, forming a colored layer combining dichromium oxide and ferric oxide with a thickness of 5nm; The transparent interference layer of silicon dioxide has a thickness of 10nm; the surface of the optical crystal layer has a honeycomb structure.

[0049] Vacuum coating equipment is used to evaporate and depos...

Embodiment 2

[0056] Using vacuum coating equipment, using 316 stainless steel as a target material, a mirror-surface 316 stainless steel film layer with a thickness of 80nm is evaporated on the substrate by vacuum sputtering coating method to obtain a mirror-surface 316 stainless steel substrate.

[0057] Use a femtosecond laser to laser engrave the thin film layer of the deposited mirror surface 316 stainless steel substrate to make a laser active layer. The single pulse energy of the laser is 0.022mJ, the distance of the abscissa of the laser light is 2.5 microns, and the distance of the ordinate of the laser light is 5 microns, forming a colored layer combining titanium nitride and ferrous disulfide with a thickness of 8nm; at the same time, it also produces titanium dioxide The transparent interference layer has a thickness of 10nm; the surface structure of the optical crystal layer is grating-like.

[0058] Vacuum coating equipment is used to evaporate and deposit a transparent compou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Median diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap