Method for constructing high-yield glutathione recombinant strain and application

A technology of glutathione and recombinant strains, applied in the field of bioengineering, can solve the problems of easy oxidation and high cysteine price, and achieve the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

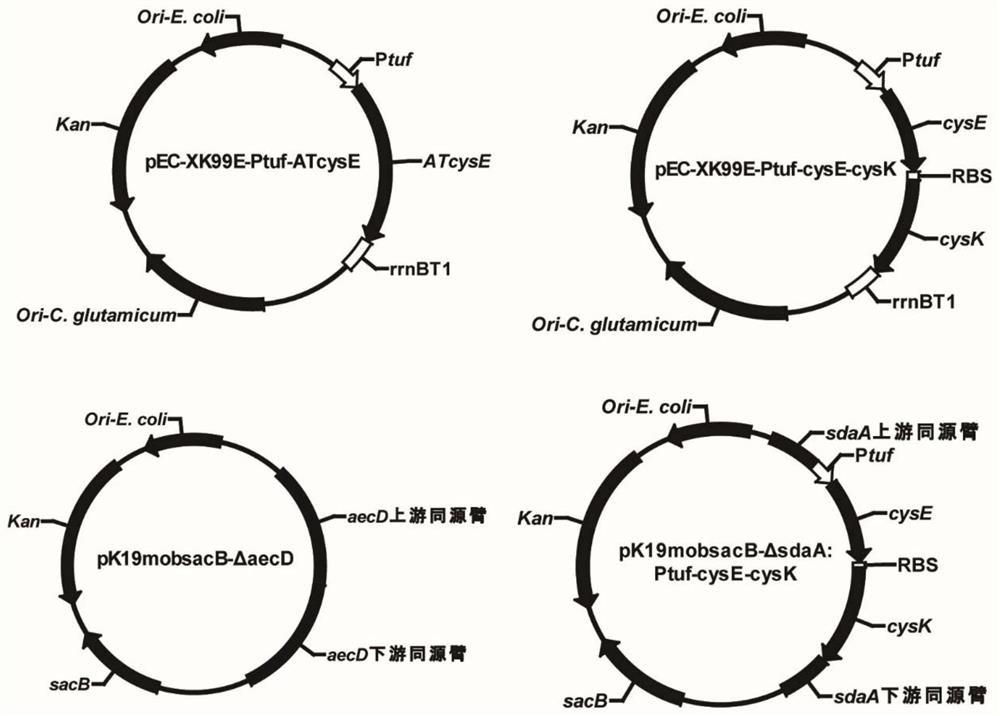

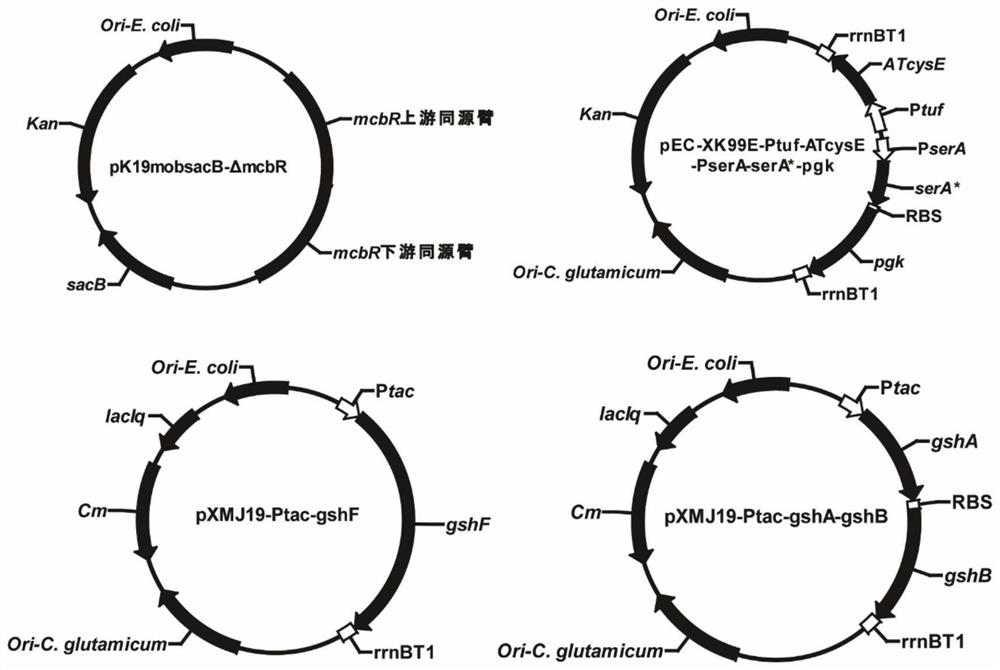

[0021] The construction of embodiment 1 recombinant plasmid

[0022] In this example, plasmids for knockout and knockin and expression of related genes in Corynebacterium glutamicum were respectively constructed, and the plasmid map is as follows figure 1 with figure 2 shown.

[0023] 1.1 Helper plasmid pEC-XK99E-P tuf -ATcysE and pEC-XK99E-P tuf -build of cysE-cysK

[0024] Plasmid pEC-XK99E is linearized with primer pair pEC-XK99E1-For(SEQ ID No.1) / pEC-XK99E1-Rev(SEQ ID No.2), the fragment contains kanamycin resistance gene, E. coli replicon , Corynebacterium glutamicum replicon and rrnBT1 terminator; Primer pair Ptuf-ATcysE-For (SEQ ID No.3) / Ptuf-ATcysE-Rev (SEQ ID No.4) from pGH-Ptuf-ATcysE plasmid (Jierui Biology Synthesis, amplified Ptuf-ATcysE fragment in SEQ ID No.5). The two fragments were circularized by Gibson recombination to construct plasmid pEC-XK99E-Ptuf-ATcysE.

[0025] Utilize the primer pair pEC-XK99E2-For(SEQ ID No.6) / pEC-XK99E2-Rev(SEQ ID No.7) to ...

Embodiment 2

[0038] Example 2 Constructing GSH high-yield recombinant strains CgGsh-13032-1 and CgGsh-13032-2 with Corynebacterium glutamicum ATCC13032 as the starting bacterium

[0039] The wild-type Corynebacterium glutamicum ATCC13032 was used as the starting bacterium, and the plasmid pXMJ19-Ptac-gshF was electrotransduced, and the bacterial solution was coated with chloramphenicol-containing BHIS plate for culture, and the correct transformant was obtained after screening, which was named CgGsh-13032-1.

[0040] Using wild-type Corynebacterium glutamicum ATCC13032 as the starting bacterium, the plasmid pK19mobsacB-ΔaecD was knocked out by electroporation to construct a cysteine desulfhydrylase-deleted strain of Corynebacterium glutamicum. The specific operation process is as follows:

[0041] (2) Extract the plasmid pK19mobsacB-ΔaecD from Escherichia coli DH5α, and wash it with pH 8.0 water for later use

[0042] (2) Electroporation of the plasmid pK19mobsacB-ΔaecD to wild-type Cor...

Embodiment 3

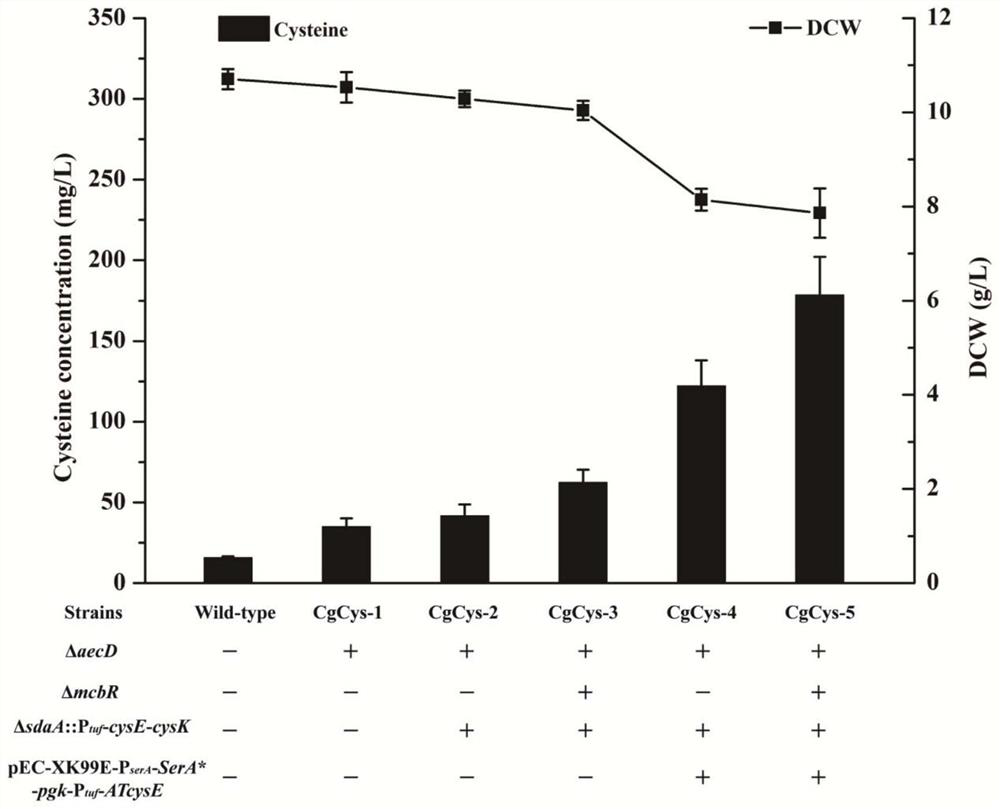

[0048] Example 3 Taking Corynebacterium glutamicum ATCC13032 as the starting strain cysteine synthesis enhanced strain to synthesize cysteine

[0049] The medium formula used in this embodiment is as follows:

[0050] Pick the activated single colony and put it in 1-100mL seed culture medium, cultivate it at 25-37℃, 50-500rpm for 5-30h, press

[0051] 0.1-30% inoculum amount was transferred to 1-500mL seed medium, cultivated at 25-37℃, 50-500rpm for 5-30h, and then pressed

[0052]The initial OD600 is 0.1-3 and transferred to 1-10L / 3-50L fermenter; the pH is adjusted to 5.0-8.0 by adding ammonia water, and the

[0053] Control the dissolved oxygen to 10-50% by controlling the speed and aeration rate; add 0-100mM glycine in the early logarithmic period,

[0054] Add 0-100mM glycine and 0-20g / L sodium thiosulfate.

[0055] Seed medium: 1~20g / L glucose, 0.5~2g / L yeast extract, 1~5g / L peptone, 1~3g / L

[0056] (NH4)2SO4, 0.1~1g / L K2HPO4, 0.1~1g / L KH2PO4.

[0057] Fermentatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com