Method for synthesizing anisonitrile through indirect electrocatalysis

An anise nitrile and electrocatalysis technology, applied in electrolysis process, electrolysis components, electrolysis organic production and other directions, can solve the problems of large amount of organic solvent, difficult purification treatment, large amount of waste, etc., and achieve no metal residue and atom economy. The effect of strong and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

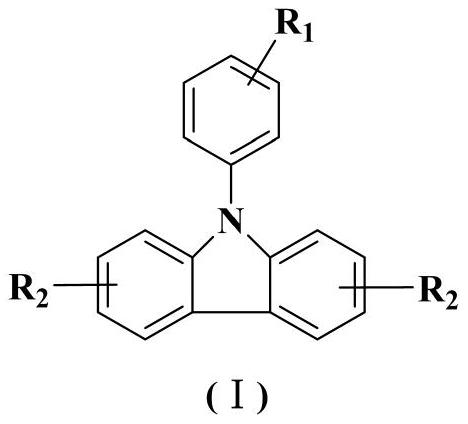

Method used

Image

Examples

Embodiment 1

[0047] Add 0.0272g p-methoxybenzaldehyde, 0.0040g electrocatalyst 2c, 0.0492g hydroxylamine sulfate, 0.3419g tetrabutylammonium perchlorate, 8mL solvent (volume ratio CH 3 CN:CH 2 Cl 2 =4:1), 2mL distilled water, 50℃, Pt as anode, Pt as cathode, Ag / AgNO 3 (0.01MAgNO 3 Acetonitrile solution) electrode was used as a reference electrode, electrolyzed at a constant potential of 1.5V for 9h to obtain the target product anisonitrile. The yield of electrolysis products was analyzed by gas chromatography GC, and the analysis method was the area normalization method. The product yield is 95% as shown in Table 1. The reaction solution was extracted with anhydrous ether (5mL×3), dried over anhydrous sodium sulfate, purified by column chromatography (petroleum ether / ethyl acetate=15:1), and then characterized.

[0048] The product structure is characterized by: 1 HNMR (500MHz, CDCl 3 )δ: 3.86(s, 3H), 6.96(d, J=8.5Hz, 2H), 7.59(d, J=8.0Hz, 2H) GC-MS (EI, 70eV) m / z: 133.05[M] + .

Embodiment 2-4、 comparative example 1

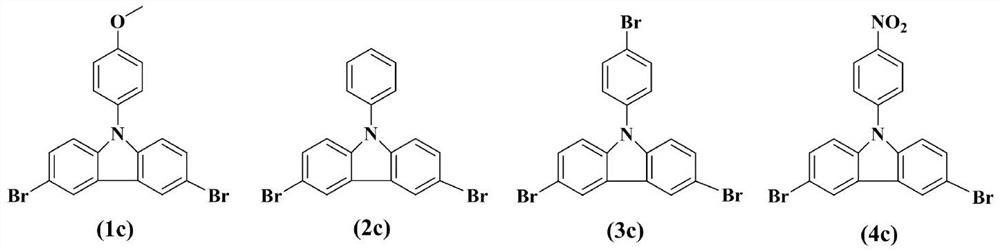

[0050] Reaction steps and reaction process are the same as embodiment 1, and difference is that electrocatalyst is respectively replaced by equimolar 0.0033g 1c (embodiment 2), 0.0048g 3c (embodiment 3), 0.0045g 4c (embodiment 4) and The above constant potential electrolysis experiment was carried out without adding electrocatalyst (comparative example 1), and the results are listed in Table 1.

[0051] Table 1 Electrolysis of p-methoxybenzaldehyde under the action of different electrocatalysts to generate anisonitrile.

[0052]

[0053]

[0054] It can be seen from Table 1 that all electrocatalysts 1c-4c can be used as electrocatalysts in the field of aromatic aldehyde electrooxidation to synthesize aromatic nitriles. When 2c is used as an electrocatalyst, the yield of the target product is up to 95%, so the electrocatalyst is preferably 2c (Example 1).

Embodiment 5-10

[0056] Reaction steps and reaction process are with embodiment 1, and difference is that temperature of reaction is 5 ℃ (embodiment 5), 20 ℃ (embodiment 6), 25 ℃ (embodiment 7), 30 ℃ (embodiment 8), 40 ℃ ℃ (embodiment 9), 60 ℃ (embodiment 10), carry out above-mentioned constant potential electrolysis experiment, the result is listed in table 2.

[0057] The electrolysis result of table 2 different reaction temperatures

[0058]

[0059] From the above reaction results, it can be seen that the reaction temperature is preferably 50° C. (Example 1).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com