Aluminum alloy flexible cable with high tensile strength and preparation method thereof

A tensile strength, aluminum alloy technology, used in flexible cables, cable/conductor manufacturing, insulated cables, etc., can solve the problems of large differences in electrical conductivity, low electrical conductivity, low strength, etc., and achieve high processing efficiency. Low cost and the effect of improving tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

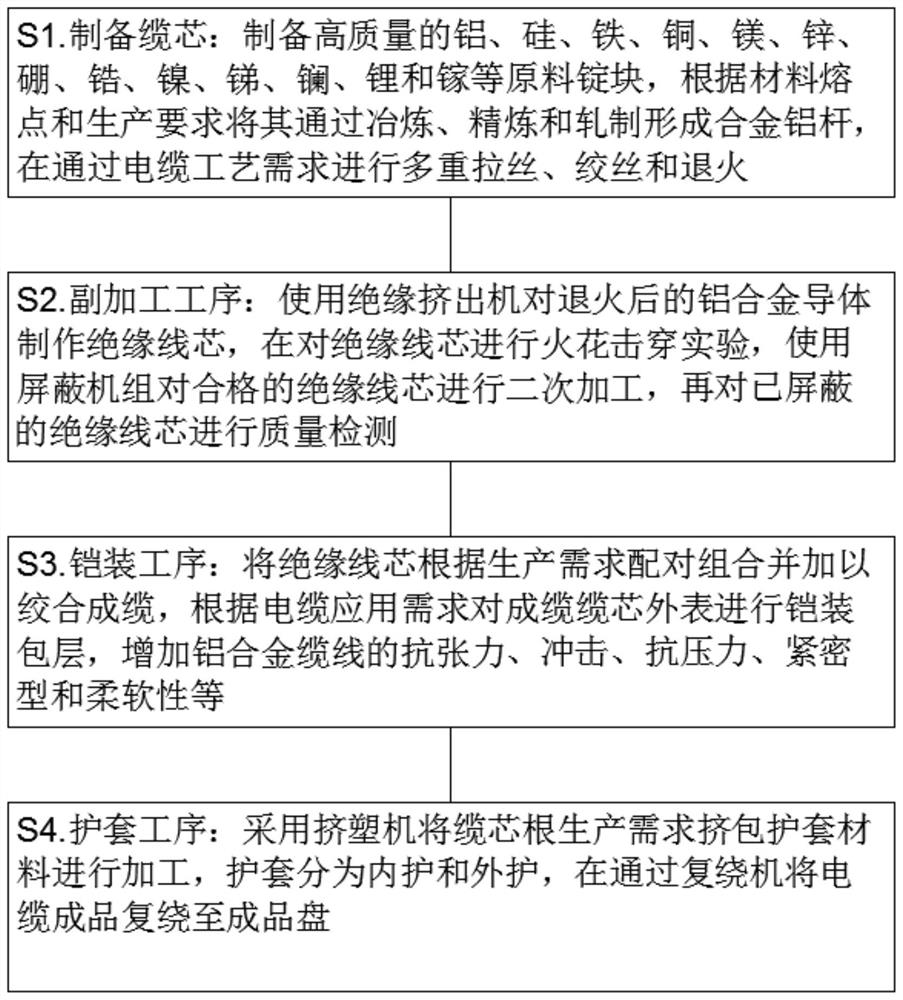

[0022] Embodiment one: comprise following production ratio and assembly procedure:

[0023] S1. Preparation of cable core: prepare high-quality raw material ingots such as aluminum, silicon, iron, copper, magnesium, zinc, boron, zirconium, nickel, antimony, lanthanum, lithium and gallium, and pass them through smelting according to the melting point of the material and production requirements , Refining and rolling to form alloy aluminum rods, and perform multiple drawing, twisting and annealing according to the requirements of cable technology;

[0024] S2. Secondary processing procedure: use an insulating extruder to make insulated wire cores from the annealed aluminum alloy conductors, conduct spark breakdown experiments on the insulated wire cores, use shielding units to perform secondary processing on qualified insulated wire cores, and then Quality inspection of shielded insulated cores;

[0025] S3. Armoring process: pair and combine insulated wire cores according to p...

Embodiment 2

[0034] Embodiment two: comprise following production ratio and assembly procedure:

[0035] S1. Preparation of cable core: prepare high-quality raw material ingots such as aluminum, silicon, iron, copper, magnesium, zinc, boron, zirconium, nickel, antimony, lanthanum, lithium and gallium, and pass them through smelting according to the melting point of the material and production requirements , Refining and rolling to form alloy aluminum rods, and perform multiple drawing, twisting and annealing according to the requirements of cable technology;

[0036] S2. Secondary processing procedure: use an insulating extruder to make insulated wire cores from the annealed aluminum alloy conductors, conduct spark breakdown experiments on the insulated wire cores, use shielding units to perform secondary processing on qualified insulated wire cores, and then Quality inspection of shielded insulated cores;

[0037] S3. Armoring process: pair and combine insulated wire cores according to p...

Embodiment 3

[0046] Embodiment three: comprise following production ratio and assembly procedure:

[0047] S1. Preparation of cable core: prepare high-quality raw material ingots such as aluminum, silicon, iron, copper, magnesium, zinc, boron, zirconium, nickel, antimony, lanthanum, lithium and gallium, and pass them through smelting according to the melting point of the material and production requirements , Refining and rolling to form alloy aluminum rods, and perform multiple drawing, twisting and annealing according to the requirements of cable technology;

[0048] S2. Secondary processing procedure: use an insulating extruder to make insulated wire cores from the annealed aluminum alloy conductors, conduct spark breakdown experiments on the insulated wire cores, use shielding units to perform secondary processing on qualified insulated wire cores, and then Quality inspection of shielded insulated cores;

[0049] S3. Armoring process: pair and combine insulated wire cores according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com