Reactive polysiloxane modified polyacrylate soap-free emulsion and preparation method thereof

A technology of polyacrylate and polysiloxane, applied in the field of textile auxiliaries, can solve the problem of short reaction route and achieve the effects of good stability, no environmental pollution and small particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

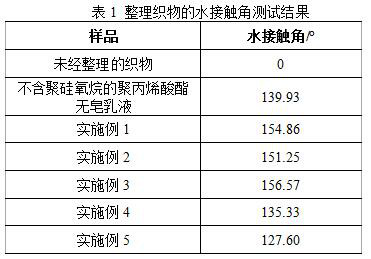

Examples

example 1

[0057] Step 1. Use a certain amount of reactive monovinyl polysiloxane monomer (Mn=2000), methyl methacrylate, and butyl methacrylate to prepare mixed monomers to obtain oil phase A; weigh allyloxy Nonylphenol polyoxyethylene ether ammonium sulfate and deionized water, allyloxy nonylphenol polyoxyethylene ether ammonium sulfate is dissolved in deionized water to form an emulsifier aqueous solution, and the aqueous phase B is prepared; the monovinyl polysilicon The mass ratio of oxane monomer (Mn=2000), methyl methacrylate, butyl methacrylate, allyloxy nonylphenol polyoxyethylene ether ammonium sulfate, and deionized water is 11:85:35:15 :128;

[0058] Step 2. Add the oil phase A prepared in step 1 to the water phase B at one time to form a mixed solution. At room temperature, use an ultrasonic disperser to ultrasonically disperse the mixed solution to obtain an O / W pre-emulsion. Ultrasonic The power is 5%, and the ultrasonic time is 20 minutes;

[0059] Step 3. Add 1 / 4 of th...

example 2

[0061] Step 1. Use a certain amount of reactive monovinyl polysiloxane monomer (Mn=2800), methyl acrylate, butyl acrylate, and lauryl acrylate to prepare mixed monomers to obtain oil phase A; weigh allyl oxide Allyloxy nonylphenol polyoxyethylene ether ammonium sulfate and deionized water, allyloxynonylphenol polyoxyethylene ether ammonium sulfate was dissolved in deionized water to form an emulsifier aqueous solution, and the aqueous phase B was prepared; the monovinyl polyoxyethylene ether The mass ratio of siloxane monomer (Mn=2800), methyl acrylate, butyl acrylate, lauryl acrylate, allyloxy nonylphenol polyoxyethylene ether ammonium sulfate, and deionized water is 9:35:65 :12:15:130;

[0062] Step 2. Add the oil phase A prepared in step 1 to the water phase B at one time to form a mixed solution. At room temperature, use an ultrasonic disperser to ultrasonically disperse the mixed solution to obtain an O / W pre-emulsion. Ultrasonic The power is 15%, and the ultrasonic time...

example 3

[0065] Step 1. Use a certain amount of reactive monovinyl polysiloxane monomer (Mn=2000), methyl methacrylate, and octadecyl acrylate to prepare mixed monomers to obtain oil phase A; weigh methacryloxy Ethyl dimethyl cetyl ammonium bromide and deionized water, allyloxynonylphenol polyoxyethylene ether ammonium sulfate was dissolved in deionized water to form an emulsifier aqueous solution, and the aqueous phase B was prepared; the monoethylene The mass ratio of polysiloxane monomer (Mn=2000), methyl methacrylate, stearyl acrylate, methacryloxyethyl dimethyl hexadecyl ammonium bromide and deionized water is 9 :58:22:15:130;

[0066] Step 2. Add the oil phase A prepared in step 1 to the water phase B at one time to form a mixed solution. At room temperature, use an ultrasonic disperser to ultrasonically disperse the mixed solution to obtain an O / W pre-emulsion. Ultrasonic The power is 5%, and the ultrasonic time is 5 minutes;

[0067] Step 3. Add 1 / 2 of the O / W pre-emulsion ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com