A water-based inorganic flame-retardant luminous coating

A luminescent coating and inorganic flame retardant technology, applied in the field of coatings, can solve the problems that are not conducive to the improvement of flame retardant performance and multi-functionalization, the inability of long afterglow powder to emit brightness, the failure of long afterglow powder, etc., so as to avoid the adverse effects of afterglow powder. , to eliminate the problem of high pollution, the effect of excellent flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

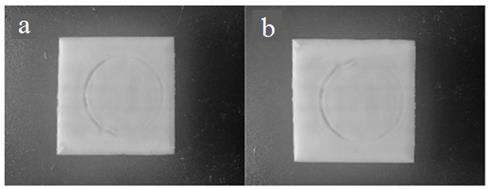

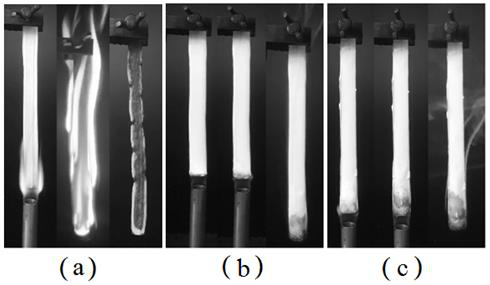

[0036] Weigh 55g of aluminum dihydrogen phosphate aqueous solution, 2g of zirconium phosphate, 2g of ammonium dihydrogen phosphate and 1g of titanium oxide into a container, stir at a speed of 600rpm for 1h, ultrasonically treat in an ultrasonic machine for 0.5h, and then stir at a speed of 600rpm 3h. After mixing evenly, slowly add 5 g of basic magnesium carbonate and 5 g of water while stirring to obtain the first mixed liquid with a viscosity of 15 Pa·s. Then stir at a speed of 100 rpm for 6 hours to mix the first mixed solution evenly and eliminate air bubbles to prepare a flame retardant coating. Weigh 12g of polyvinyl butyral and 5g of 1H,1H,2H,2H-perfluorodecyltrimethoxysilane and dissolve it in 50g of ethanol, raise the temperature to 80°C, add ammonia water drop by drop, and obtain a pH value of 8 The second mixed solution was stirred at a speed of 500rpm for 5h, cooled to room temperature, and the remaining ethanol and ammonia water were evaporated to obtain the pro...

Embodiment 2

[0038] Weigh 55g of magnesium dihydrogen phosphate liquid, 3g of zirconium phosphate, 2g of sodium polyphosphate, and 1g of alumina into a container, stir at a speed of 700rpm for 1.5h, then ultrasonically treat it in an ultrasonic machine for 1h, and then stir at a speed of 800rpm 2.5h. After mixing evenly, while stirring again, slowly add 7.5 g of basic magnesium carbonate and 6 g of water to obtain the first mixed liquid with a viscosity of 15 Pa·s. Then stir at a speed of 50 rpm for 6 hours to mix the first mixed solution evenly and eliminate air bubbles to prepare a flame retardant coating. 10 g of polyvinyl butyral and 4 g of trimethoxy-1H,1H,2H,2H-tridecafluoro-n-octylsilane were weighed and dissolved in 50 g of ethanol, and the reaction temperature was raised to 80°C. Then, ammonia water was added dropwise to the above solution mixture to obtain a second mixed solution with a pH value of 9, which was stirred at 400 rpm for 6 h, cooled to room temperature and the remai...

Embodiment 3

[0040] Preparation of flame retardant coating, weigh 30g aluminum dihydrogen phosphate liquid, 30g dimagnesium hydrogen phosphate liquid, 2g calcium dihydrogen phosphate, 2g ammonium dihydrogen phosphate, 1g zirconium phosphate, 1.5g zinc oxide and pour them into the container, at 800rpm After stirring at a rotational speed for 2 h, ultrasonically treat for 0.5 h in an ultrasonic machine, and then stir at a rotational speed of 800 rpm for 4 h. After mixing evenly, while stirring again, slowly add 8.5 g of basic magnesium carbonate and 8 g of water to obtain the first mixed liquid with a viscosity of 16.5 Pa·s. Then stir at a speed of 50 rpm for 6 hours to mix the first mixed solution evenly and eliminate air bubbles to prepare a flame retardant coating. Finally, brush the prepared flame-retardant paint on the wood chip and let it dry at room temperature. 15g of polyvinylpyrrolidone and 7g of triethoxy-1H,1H,2H,2H-tridecafluoro-n-octylsilane were weighed and dissolved in 55g o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com