Particle-stabilized foams using sustainable materials

A technology of foam and particles, applied in the direction of climate sustainability, sustainable waste treatment, ceramic material production, etc., can solve problems such as high carbon dioxide emissions and large amounts of surfactants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment I

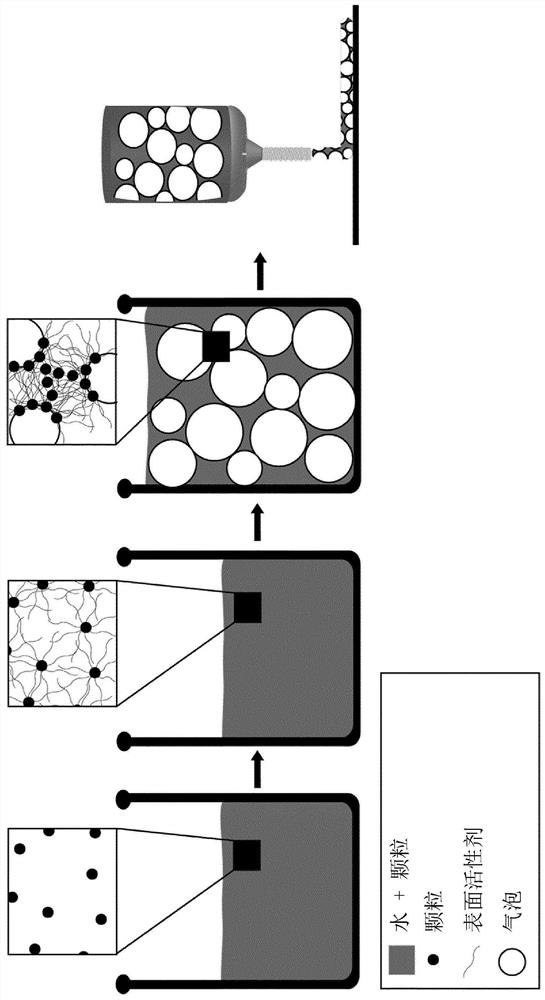

[0107] Example I: Mechanical foaming and addition of cement

[0108] Step 1: Optionally grinding the aluminosilicate particles obtained from the secondary raw material.

[0109] Step 2: Dissolve the long-chain surfactant in water.

[0110] Step 3: Add optionally milled aluminosilicate particles to the dissolved long-chain surfactant, with the particles dispersed by mixing at 200 rpm.

[0111] Step 4: Adjust the pH of the suspension in step 3 to a pH of 9-10.

[0112] Step 5: Foam the suspension obtained in step 4 using a high shear mixer at 800 to 1000 revolutions per minute.

[0113] Step 6: Disperse the cement in water.

[0114] Step 7: Mix the foamed suspension from step 4 and the cement dispersed in water from step 5 with a high shear mixer at 800 to 1000 rpm.

[0115] Step 8: Cast or extrude or 3D print the foamed suspension mixed in step 7.

[0116] Step 9: Make the foamed suspension cast or extruded or 3D printed in step 8 by covering or placing in a humidity cha...

Embodiment II

[0118] Example II: Mechanical Foaming and Addition of Alkali Solution

[0119] Step 1: Optionally grinding the aluminosilicate particles obtained from the secondary raw material.

[0120] Step 2: Dissolve the long-chain surfactant in water.

[0121] Step 3: Add optionally milled aluminosilicate particles to the dissolved long-chain surfactant, with the particles dispersed by mixing at 200 rpm.

[0122] Step 4: Adjust the pH of the suspension in step 3 to a pH of 9-10.

[0123] Step 5: Foam the suspension obtained in step 4 using a high shear mixer at 800 to 1000 revolutions per minute.

[0124] Step 6: To the foamed suspension obtained in step 5, sodium silicate solution (Na 2 O SiO 2 ), wherein the foamed suspension in step 5 is contained in one cartridge and the sodium silicate solution is contained in the other cartridge.

[0125] Step 7: Cast or extrude or 3D print the suspension mixed in step 6.

[0126] Step 8: Allow the mixed suspension cast or extruded or 3D pr...

Embodiment III

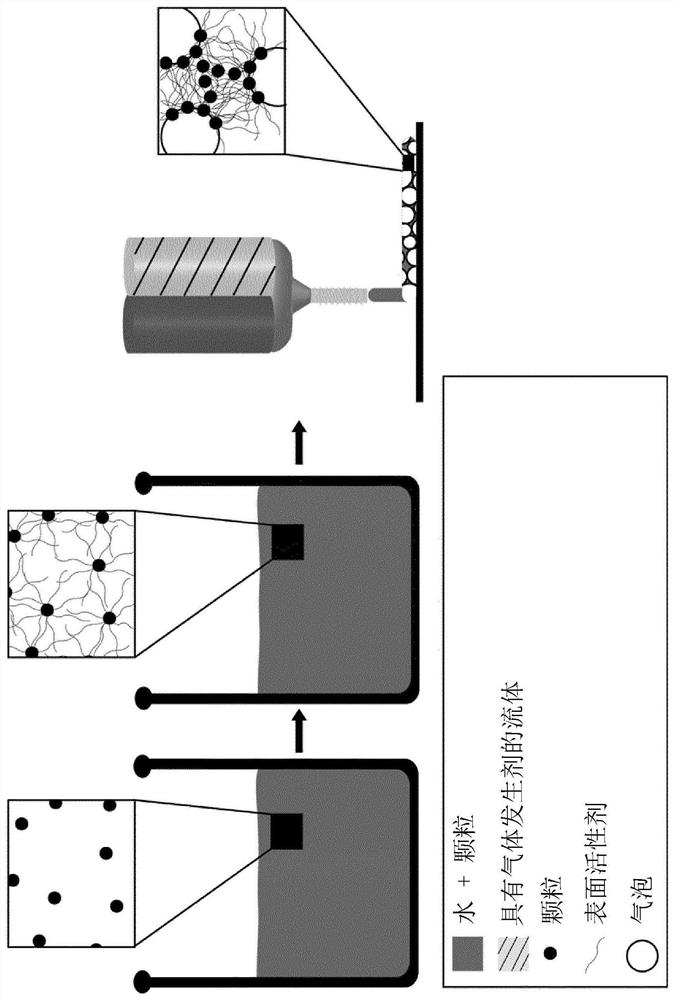

[0128] Example III: In Situ Foaming and Alkaline Solutions

[0129] Step 1: Optionally grinding the aluminosilicate particles obtained from the secondary raw material.

[0130] Step 2: Dissolve the long-chain surfactant in water.

[0131] Step 3: Add optionally milled aluminosilicate particles to the dissolved long chain surfactant.

[0132] Step 4: Adjust the pH of the suspension in step 3 to a pH of 9 to 10 and add a catalyst such as manganese oxide (MnO).

[0133] Step 5: Water and hydrogen peroxide (H 2 o 2 ) to prepare an alkaline solution.

[0134] Step 6: Mix the suspension from step 4 and the solution from step 5 using a twin static mixer with a single screw extruder.

[0135] Step 7: Cast or extrude or 3D print the suspension mixed in step 6.

[0136] Step 8: Allow the mixed suspension cast or extruded or 3D printed in step 7 to solidify by overlaying at 40 to 80°C, preferably 60°C for 24h.

[0137] Step 9: Drying the porous article in step 8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com