A deep heating cold end system for direct air cooling units

A technology of air-cooling units and air-cooling machines, applied in heating systems, space heating and ventilation, direct contact heat exchangers, etc., can solve problems such as difficult construction, unfavorable water saving, and large exhaust steam extraction pipelines, etc. Achieve enhanced safety and reliability, obvious energy-saving effects, and low space requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

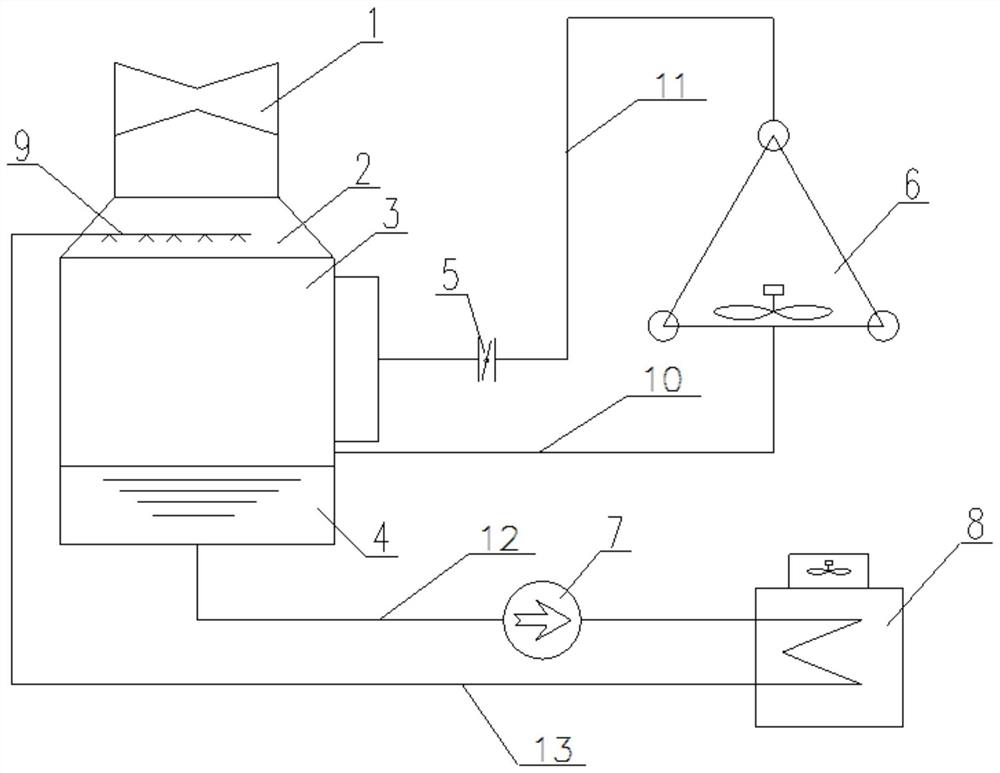

[0036] This embodiment is basically as figure 1Shown: This embodiment provides a direct air cooling unit deep heating cold end system, the system includes a low pressure cylinder 1, a steam exhaust device, a cooling water spray mechanism 9, an air cooling island 6 and an air cooling power tower 8, wherein the low pressure The cylinder 1 has an exhaust steam outlet for exhausting the exhaust steam of the steam turbine, and the exhaust steam device is connected with the exhaust steam outlet, so that the exhaust steam can enter the exhaust steam device; the cooling water spray mechanism 9 provided in this embodiment is arranged in the exhaust steam. In the device, so that the cooling water can exchange heat with the exhausted steam in the exhaust device and form condensed water.

[0037] Crucially, this embodiment provides a technical improvement in that the exhausted steam of the turbine is drawn out for condensation and water is used as the heat flow medium for cooling, that is...

Embodiment 2

[0041] The second embodiment is basically the same as the first embodiment, with the difference that: this embodiment provides a deep heating and cold end system for a direct air-cooled unit. The return line 11 connected with the steam exhaust device, so that the condensed water cooled by the air cooling island 6 can enter the steam exhaust device through the return line 11, and flow into the hot well of the steam exhaust device, so that the air cooling can be directly cooled in this embodiment. The condensed water cooled by the island 6 is introduced into the exhaust device for reheating, so as to achieve the purpose of reducing the oxygen content of the condensed water in the exhaust device.

Embodiment 3

[0043] The third embodiment is basically the same as the second embodiment, the difference is that: this embodiment provides a direct air-cooled unit deep heating cold end system, as the preferred embodiment of the second embodiment, the air-cooled power tower 8 provided in this embodiment is provided. It is equipped with a return pipe 2 13 connected to the steam exhaust device, so that the condensed water cooled by the air-cooling power tower 8 can enter the steam exhaust device through the return pipe 2 13, and flow into the steam exhaust device after mixing with the exhausted steam for heat exchange. In the hot well 4; at the same time, a condensate pump 7 is arranged on the drainage pipe 12 connected with the air-cooled power tower 8 and the steam exhaust device, so that the condensed water in the hot well 4 of the steam exhaust device can be discharged into the air-cooled power through the condensate pump 7 Tower 8.

[0044] Therefore, the design of the condensate pump 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com