Electron transport material and preparation method and application thereof

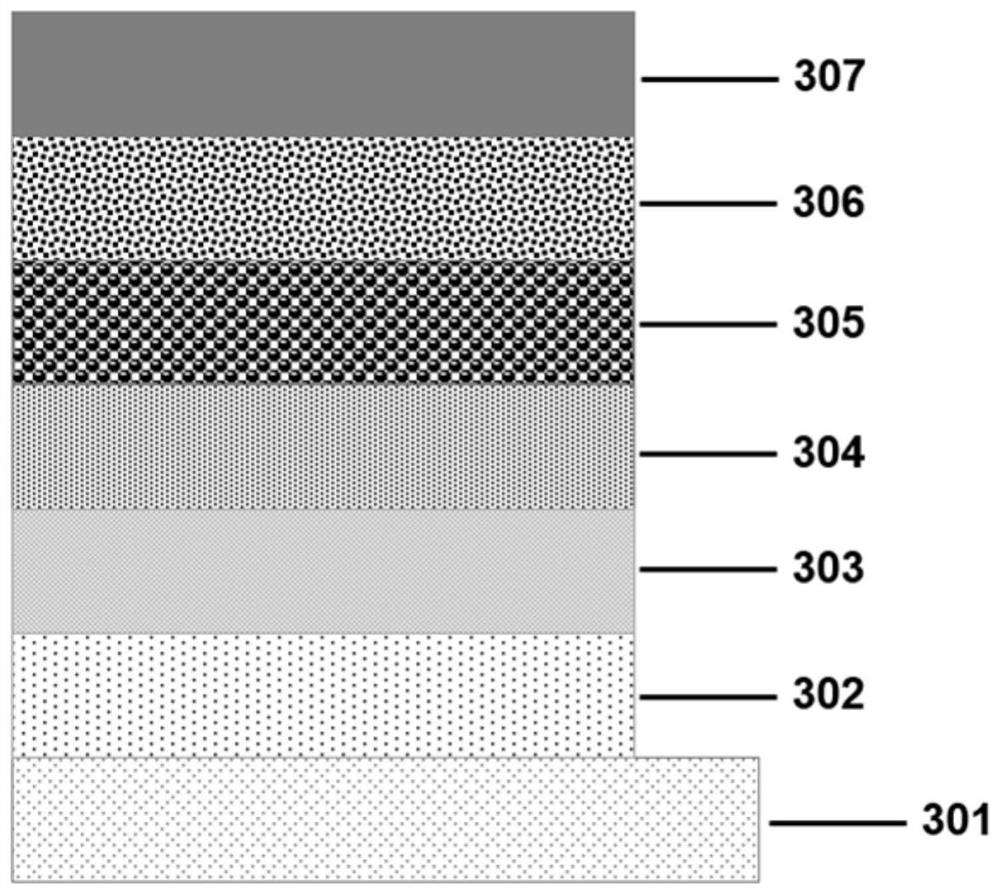

A technology of electron transport material and electron transport layer, which is applied in the field of electron transport material and its preparation, can solve the problem that the life of QLED cannot meet the standard of commercialization, and achieve the goal of reducing defect energy level, promoting charge balance and reducing surface defects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

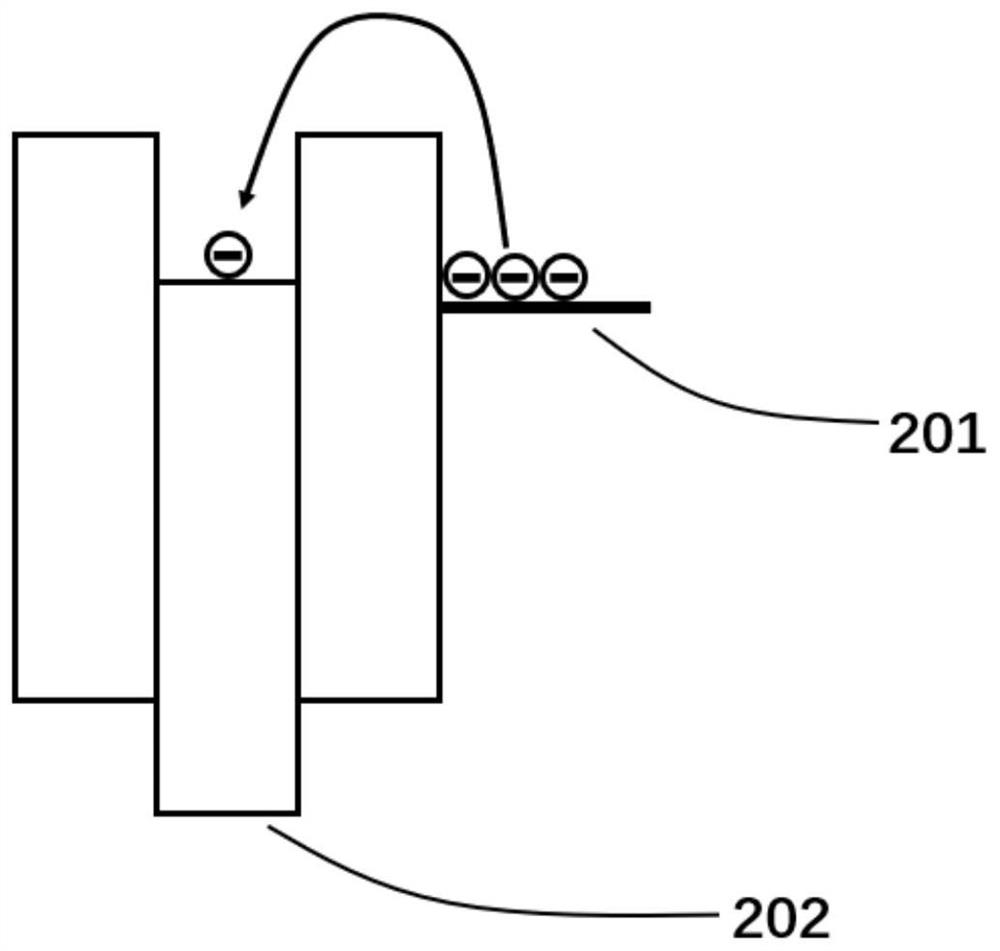

[0049]A method for preparing an electron transport material includes the following steps:

[0050]Preparation of metal oxide core nanoparticles: dissolve the metal source in a solvent, add an alkaline solution, and react for 1-2 hours to obtain metal oxide nanoparticles;

[0051]Wrap the shell material on the surface of the metal oxide nanoparticles;

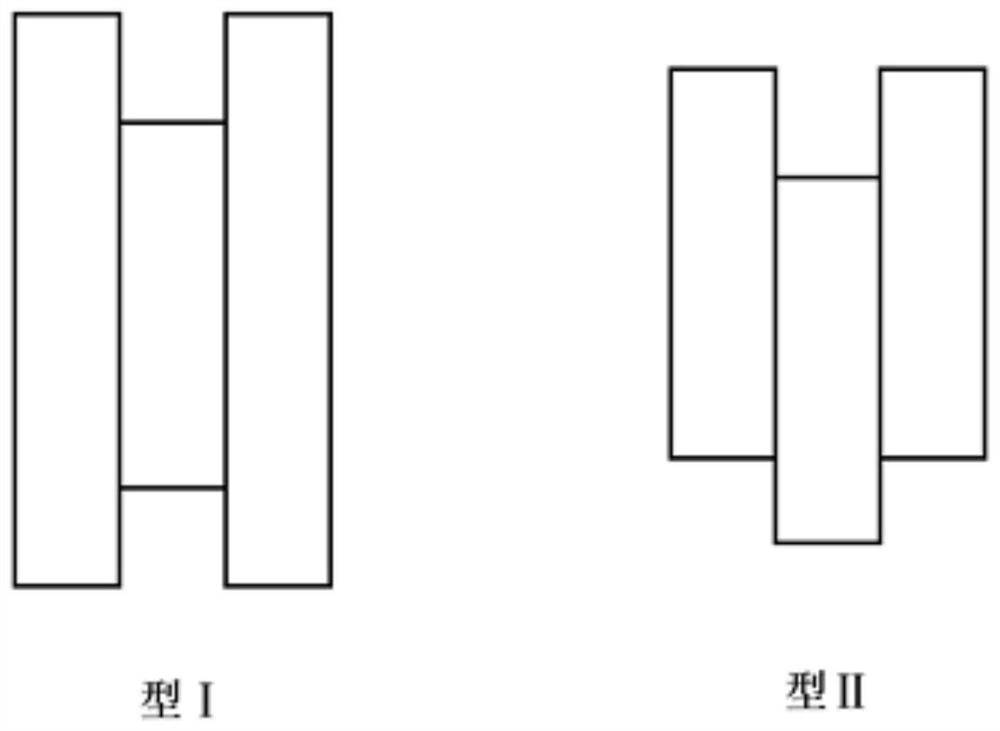

[0052]The bottom energy level of the conduction band of the material of the shell layer is smaller than the bottom energy level of the conduction band of the metal oxide nanoparticles.

[0053]Preferably, the step of wrapping a shell material on the surface of the metal oxide nanoparticles includes:

[0054]The shell material precursor is added to the metal oxide nanoparticles, and the reaction is for 1 h-4h.

[0055]When preparing the electron transport material of type II structure, the shell material precursor is preferably at least two of a sulfur source, a selenium source, a tellurium source and a zinc source.

[0056]The wrapping method is as follow...

Embodiment 1

[0069]This embodiment provides a core-shell structured ZnO / ZnS electron transport material and a preparation method thereof. The steps are as follows:

[0070](1) Dissolve 10mmol of zinc acetate dihydrate in 20ml of dimethyl sulfoxide, then take 10mmol of tetramethylammonium hydroxide and dissolve in 10ml of ethanol, add the tetramethylammonium hydroxide solution dropwise to zinc acetate In the solution and heated to 60℃, keep stirring, react for 1 hour;

[0071](2) After 1 hour, when the reaction is over, add excess n-hexane to the above solution, then centrifuge to obtain ZnO precipitate, which is air-dried and dissolved in ethanol. Obtain a ZnO nanoparticle solution;

[0072](3) Take 50ml of the above-mentioned ZnO nanoparticle solution with a concentration of 10mg / ml, and then drop 10ml of sodium sulfide solution with a concentration of 0.1M into it, and stir for 1 hour;

[0073](4) After 1 hour, take 10ml of 0.1M zinc chloride solution and drop it into the above solution drop by drop, cont...

Embodiment 2

[0076]This embodiment provides a core-shell structured ZnO / ZnSe electron transport material and a preparation method thereof. The steps are as follows:

[0077](1) Dissolve 10mmol of zinc acetate dihydrate in 20ml of dimethyl sulfoxide, then take 10mmol of tetramethylammonium hydroxide and dissolve in 10ml of ethanol, add the tetramethylammonium hydroxide solution dropwise to zinc acetate In the solution and heated to 60℃, keep stirring, react for 1 hour;

[0078](2) After 1 hour, when the reaction is over, add excess n-hexane to the above solution, then centrifuge to obtain ZnO precipitate, and then dissolve in ethanol after air drying to obtain a ZnO nanoparticle solution;

[0079](3) Take 50ml of the above ZnO nanoparticle solution with a concentration of 10mg / ml, and then drop 10ml of sodium selenite solution with a concentration of 0.1M into it, and stir for 1 hour;

[0080](6) After 1 hour, take 10ml of 0.1M zinc chloride solution and drop it into the above solution drop by drop, continue...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com