Graphene@egg yolk-eggshell silicon-carbon composite material as well as preparation and application thereof

A silicon-carbon composite material and silicon-carbon material technology, which is applied in the field of materials, can solve the problems of pollution, easy corrosion of elemental silicon particles, affecting the morphology of target products, etc., and achieve the effects of high Coulomb efficiency and long-cycle capacity retention rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

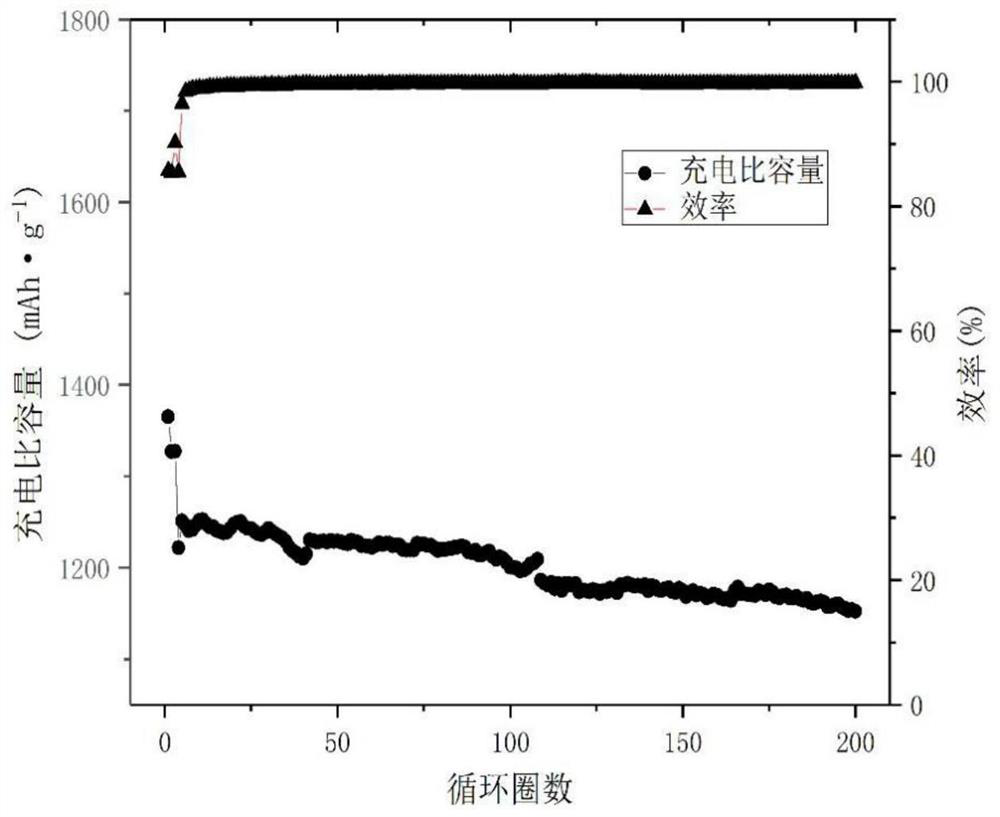

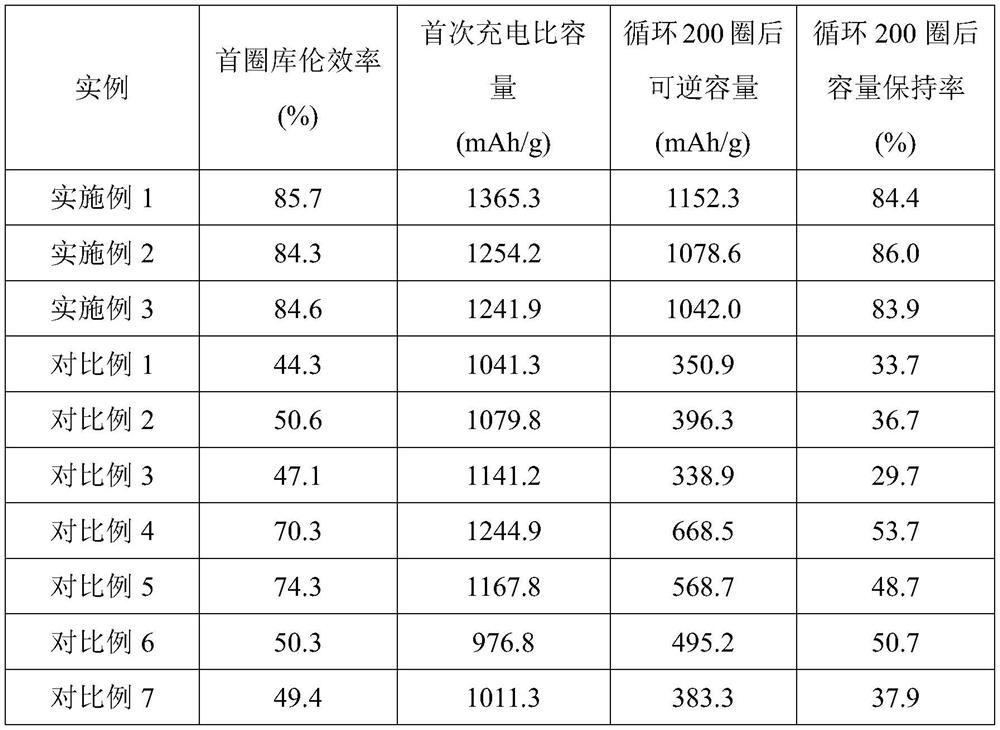

Embodiment 1

[0067] (1) ultrasonically disperse graphite oxide in dilute hydrochloric acid solution with pH=1, the liquid-solid ratio is 700:1, and add silicon-based material (D50=400nm free Shaped nano-silicon), followed by ultrasonic treatment at 50°C, the ultrasonic power is 400W, the ultrasonic frequency is 100kHz, and the ultrasonic time is 1.5h, to obtain the mixed colloidal solution. Add FeCl 3 ·6H 2 O (amorphous nano-silicon and FeCl 3 ·6H 2 The ratio of O is 10:1), after mixing, while mechanically stirring, add ammonia water with a concentration of 25-28% dropwise until pH=10, and the precipitate obtained by centrifugation is washed with deionized water until the pH of the eluate is 7. Solid A was obtained after drying.

[0068] (2) Put the solid A and ferrocene in acetone, the mass ratio of the two solids is 1:1, the liquid-solid ratio is 20:1, ultrasonically treat at 50°C, and the ultrasonic power is 800W. The frequency is 300kHz, and the ultrasonic time is 4h to obtain a m...

Embodiment 2

[0074] (1) Supersonically disperse graphite oxide in dilute hydrochloric acid solution with pH=1, the liquid-solid ratio is 500:1, and add silicon-based material (D50=200nm free Shaped nano-silicon), followed by ultrasonic treatment at 25°C, the ultrasonic power is 200W, the ultrasonic frequency is 50kHz, and the ultrasonic time is 1.0h, to obtain the mixed colloidal solution. Add NiSO 4 ·6H 2 O (amorphous nano-silicon and NiCl 2 ·6H 2 The ratio of O is 5:1), after mixing, add 0.05mol / L NaOH solution dropwise while stirring mechanically, until pH = 8, and wash the precipitate obtained by centrifugation with deionized water until the pH of the eluate is 7 , A solid was obtained after drying.

[0075] (2) Put solid A and nickelocene in glycerol, the mass ratio of the two solids is 1:2, the liquid-solid ratio is 15:1, and ultrasonically treat at 25°C with the ultrasonic power of 600W , the ultrasonic frequency was 100kHz, and the ultrasonic time was 2h to obtain a mixed solu...

Embodiment 3

[0081] (1) Ultrasonic disperse graphite oxide in dilute hydrochloric acid solution with pH=1, the liquid-solid ratio is 200:1, and add silicon-based materials (SiO with D50=400nm) according to the mass ratio of silicon-based core and graphite oxide at 5:1 1.5 ), followed by ultrasonic treatment at 0°C, the ultrasonic power is 100W, the ultrasonic frequency is 10kHz, and the ultrasonic time is 0.5h, to obtain the mixed colloidal solution. Add MnCl 2 4H 2 O(SiO 1.5 and MnCl 2 4H 2The ratio of O is 1:1), after mixing, the ammonia water with a concentration of 25-28% is added dropwise while stirring mechanically until pH = 6, and the precipitate obtained by centrifugation is washed with deionized water until the pH of the eluate is 7 , A solid was obtained after drying.

[0082] (2) Place solid A and glucose in DMF, the mass ratio of the two solids is 1:4, the liquid-solid ratio is 10:1, and ultrasonically treated at 0°C, the ultrasonic power is 400W, and the ultrasonic frequ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com