Treatment process for leftover materials generated in glycine ethyl ester hydrochloride preparation process

A technology for treating ethyl glycine hydrochloride, which is applied in the recycling field of reaction waste, and can solve the problems such as the increase of impurities in the scrap mother liquor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

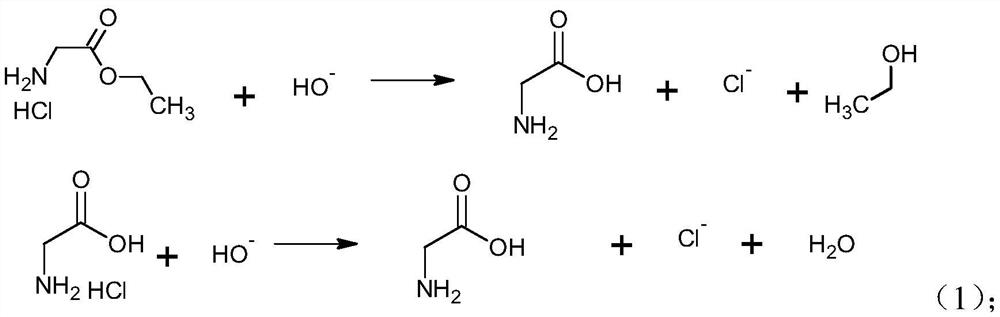

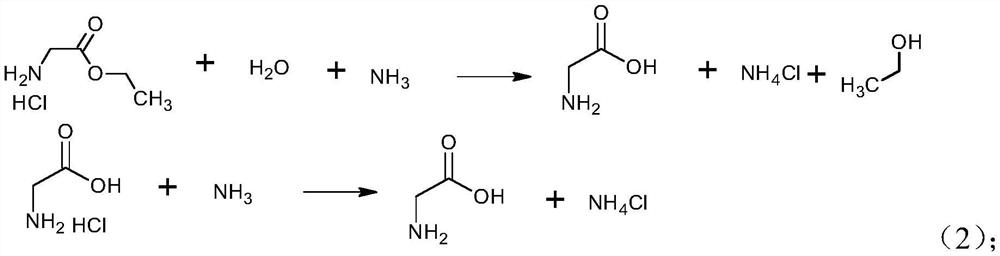

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036](1) To a glass-lined kettle a with a stirring volume of 3000L, pump 800L of the mother liquor after distillation and recovery of ethanol, stir, pump 1600L of absolute ethanol, stir for half an hour, press filter to a volume with stirring and reflux 3000L glass-lined kettle b;

[0037](2) Slowly pour ammonia gas into the glass-lined kettle b, and control the aeration speed to 1.5~2.0m3 / min, after reaching the pH value of 8, keep the pH value around 8 and keep the temperature at 55~65℃ for 2 hours, observe that a large number of white crystals appear in the kettle;

[0038](3) Pass cooling water to the jacket of the glass-lined kettle b, cool it to room temperature, keep it for 2 hours, centrifuge it, and after spin-drying, take a sample to detect that the chloride ion content in the filter cake is 0.9%, and use 95% ethanol. After washing the filter cake once, the chloride ion content in the filter cake was detected to be 0.4%. The filter cake was vacuum-dried to obtain 342.9 kg of cr...

Embodiment 2

[0041](1) To a glass-lined kettle a with a stirring volume of 3000L, pump 800L of the mother liquor after distillation and recovery of ethanol, stir, pump in 1600L of 95% ethanol, stir for half an hour, and filter to a volume with stirring and reflux. 3000L glass-lined kettle b.

[0042](2) Slowly pour ammonia gas into the glass-lined kettle b, and control the aeration speed to 1.5~2.0m3 / min, after reaching the pH value of 8, keep the pH value around 8 and keep the temperature at 55~65℃ for 2 hours, observe that a large number of white crystals appear in the kettle;

[0043](3) Pass cooling water to the jacket of the glass-lined kettle b, cool it down to normal temperature, keep it for 2 hours, centrifuge it, and after spinning dry, take a sample and check that the chloride ion content in the filter cake is 0.6%. Use 95% ethanol. After washing the filter cake once, the chloride ion content in the filter cake was detected to be 0.35%. The filter cake was vacuum-dried to obtain 316.3kg of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com