Method for detecting residues of eight organic matters in ion exchange resin by adopting headspace gas phase method

A technology of ion exchange resin and headspace gas phase, applied in the field of chemical analysis, to achieve the effect of optimizing chromatographic conditions, good separation, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

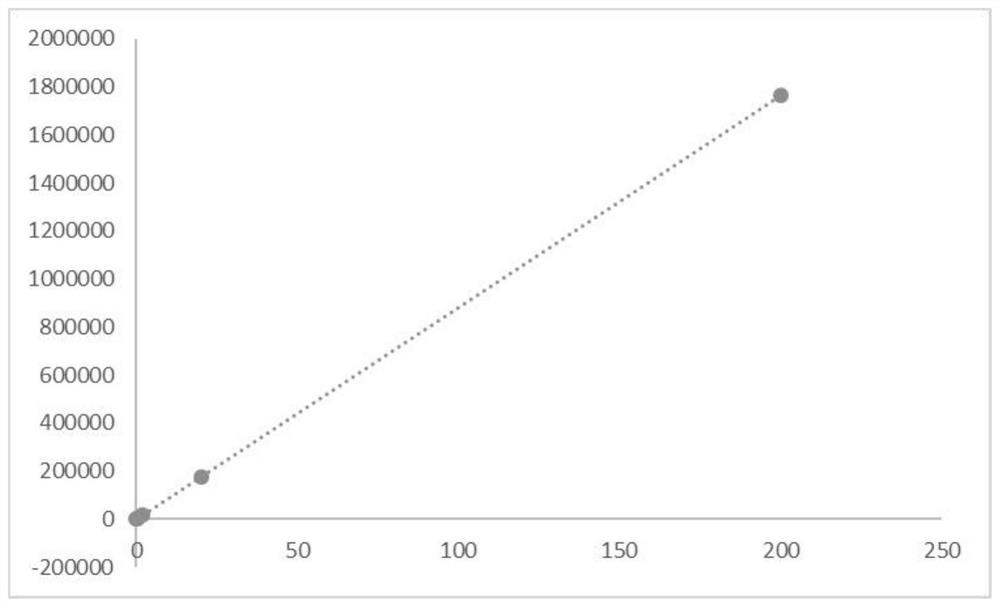

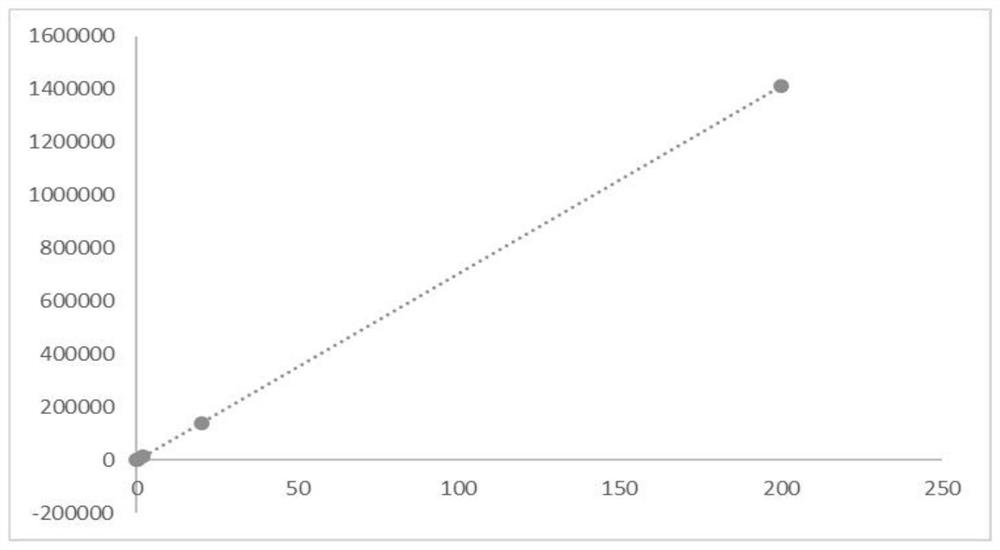

[0061] (1) Preparation of standard working solution:

[0062] Prepare standard working solution of methyl isopropyl ketone: 0.02μg / mL, 0.2μg / mL, 2μg / mL, 20μg / mL, 200μg / mL,

[0063] Prepare standard working solution of methyl methacrylate: 0.02μg / mL, 0.2μg / mL, 2μg / mL, 20μg / mL, 200μg / mL,

[0064] Prepare 3-pentanone standard working solution: 0.02μg / mL, 0.2μg / mL, 2μg / mL, 20μg / mL, 200 μg / mL,

[0065] Prepare standard working solution of methyl butyrate: 0.02μg / mL, 0.2μg / mL, 2μg / mL, 20μg / mL, 200μg / mL,

[0066] Prepare 1,2-dichloroethane standard working solution: 0.02μg / mL, 0.2μg / mL, 2μg / mL, 20μg / mL, 200μg / mL,

[0067] Prepare 1,3-diethylbenzene standard working solution: 0.02μg / mL, 0.2μg / mL, 2μg / mL, 20μg / mL, 200μg / mL,

[0068] Prepare 1,4-diethylbenzene standard working solution: 0.02μg / mL, 0.2μg / mL, 2μg / mL, 20μg / mL, 200μg / mL,

[0069] Prepare m-dichlorobenzene standard working solution: 0.02μg / mL, 0.2μg / mL, 2μg / mL, 20μg / mL, 200μg / mL; the solvents are dimethyl sulfoxide stand...

Embodiment 2

[0090] (1) Optimization of headspace sampler equilibrium temperature:

[0091] On the basis of Example 1, under the condition of other parameters being fixed, samples were injected after equilibrating at constant temperature of 50, 60, 70, and 80°C in the headspace for 30 minutes, and the influence of different equilibrium temperatures on the peak area of the target was investigated.

[0092] See Figure 15 ~ Figure 18 . The results show that in the range of 40-90°C, the peak areas of the eight organic compounds increase with the increase of temperature, and the analysis sensitivity is higher; Condensation, resulting in reduced accuracy and possibly increased interference. Combined with the constant temperature state control performance of the sampler, headspace pressure resistance and tightness and other factors, 80°C was selected as the standard equilibrium temperature.

[0093] (2) Optimization of headspace sampler equilibration time:

[0094] On the basis of Example ...

Embodiment 3

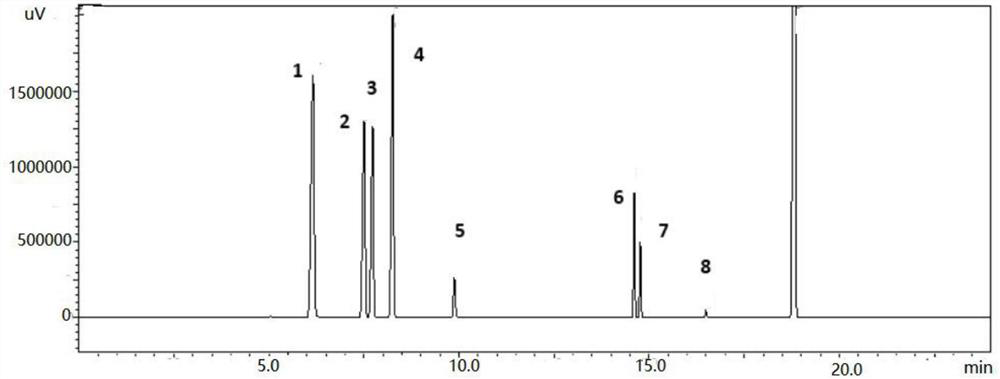

[0097] (1) Selection of chromatographic column:

[0098] When using DB-624 (30m×0.53mm, 1.0μm) quartz capillary column and DB-WAX (30m×0.25mm×0.25μm) quartz capillary column to separate the mixed standard, the 8 kinds of organic substances could not be separated, see Figure 22 ~ Figure 24 , it can be seen that the separation effect of the sample is good when using DB-23 (30m×0.25mm×0.25μm).

[0099] (2) The solvent is replaced by methanol: see the peak results when methanol is used as the solvent Figure 25 , may overlap with the target organism and result in inaccurate results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com