Preparation method and application of pyridylamino composite hydrogel adsorbent

A composite hydrogel, pyridineamine-based technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water pollutants, etc., can solve the problems of slow adsorption rate and low adsorption capacity, and achieve adsorption promotion and synthesis steps. Simple, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

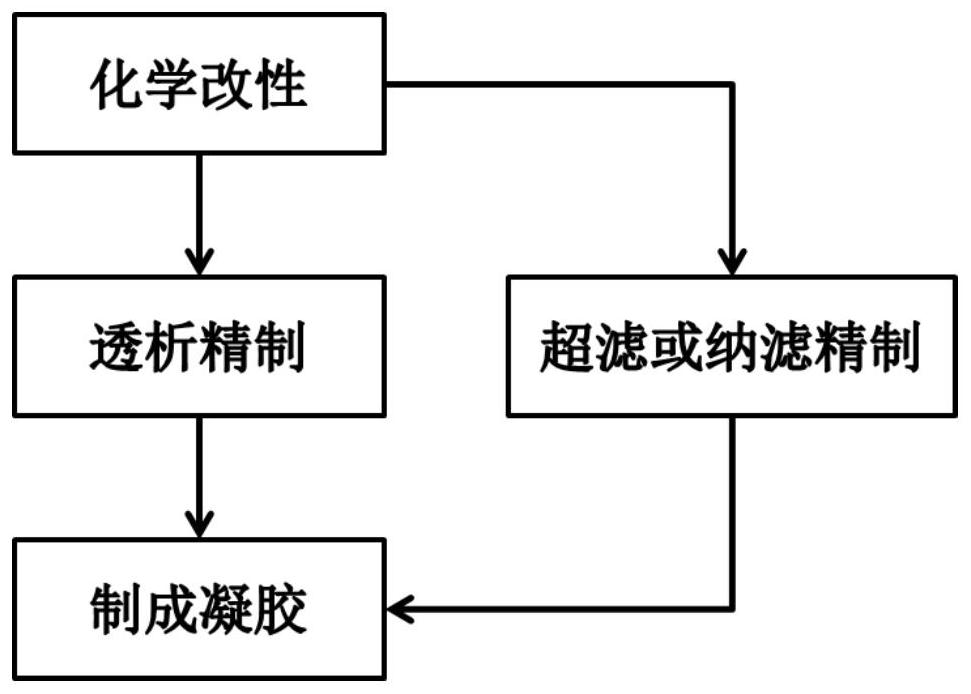

[0039] The preparation and application of a pyridine amine-based composite hydrogel adsorbent adopts the following steps:

[0040] (a) Dissolve 2.00g of anhydrous sodium carbonate and 3.000g of 2-chloromethylpyridine hydrochloride in 50mL of deionized water successively, add 10mL of absolute ethanol, and then add 2.0g of 50wt% polyethyleneimine (PEI) Solution (MW 70000), stirred at room temperature to mix evenly, and reacted the mixed solution at 90°C for 2-8 hours to obtain a modified solution;

[0041] (b) Take 24 mL of the modified solution obtained in step (a) into a dialysis bag, and perform dialysis in deionized water. Control the volume ratio of deionized water to modified solution to 40. The water was changed every 1.5 hours, and the water was changed 4 times in total. Pour the dialyzed polymer solution into a beaker, heat and concentrate to obtain about 20 mL of PEIPD concentrate;

[0042] (c) Weigh 4.5 g of sodium alginate (SA) and dissolve it in 100 mL of deioniz...

Embodiment 2

[0045] The preparation and application of a pyridine amine-based composite hydrogel adsorbent adopts the following steps:

[0046] (a) Dissolve 2.25g of anhydrous sodium carbonate and 3.375g of 2-chloromethylpyridine hydrochloride in 50mL of deionized water successively, add 10mL of absolute ethanol, and then add 2.0g of 50wt% polyethyleneimine (PEI) solution (MW 70000), stirred at room temperature to mix well. The mixed solution was reacted at 90°C for 2 hours to obtain a modified solution;

[0047] (b) Take 24 mL of the modified solution obtained in step (a) into a dialysis bag, and perform dialysis in deionized water. Control the volume ratio of deionized water to modified solution to 40. The water was changed every 1.5 hours, and the water was changed 4 times in total. Pour the dialyzed polymer solution into a beaker, heat and concentrate to obtain about 20 mL of PEIPD concentrate;

[0048] (c) Weigh 4.5 g of sodium alginate (SA) and dissolve it in 100 mL of deionized ...

Embodiment 3

[0051] The preparation and application of a pyridine amine-based composite hydrogel adsorbent adopts the following steps:

[0052] (a) Dissolve 2.50g of anhydrous sodium carbonate and 3.750g of 2-chloromethylpyridine hydrochloride in 50mL of deionized water successively, add 10mL of absolute ethanol, and then add 2.0g of 50wt% polyethyleneimine (PEI) solution (MW 70000), stirred at room temperature to mix well. The mixed solution was reacted at 90°C for 2 hours to obtain a modified solution;

[0053] (b) Take 24 mL of the modified solution obtained in step (a) into a dialysis bag, and perform dialysis in deionized water. Control the volume ratio of deionized water to modified solution to 40. The water was changed every 1.5 hours, and the water was changed 4 times in total. Pour the dialyzed polymer solution into a beaker, heat and concentrate to obtain about 20 mL of PEIPD concentrate;

[0054] (c) Weigh 4.5 g of sodium alginate (SA) and dissolve it in 100 mL of deionized ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com