Quick forming device for ultra-high molecular weight polymer

An ultra-high molecular weight, molding device technology, applied in manufacturing auxiliary devices, additive manufacturing, processing platforms/substrates, etc., can solve the problems of narrow processing temperature range of ultra-high molecular weight polymers, limited application occasions, and impact on the quality of molded workpieces. Achieve the effect of flexible and changeable printing structure, adapting to a large temperature range and avoiding large heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

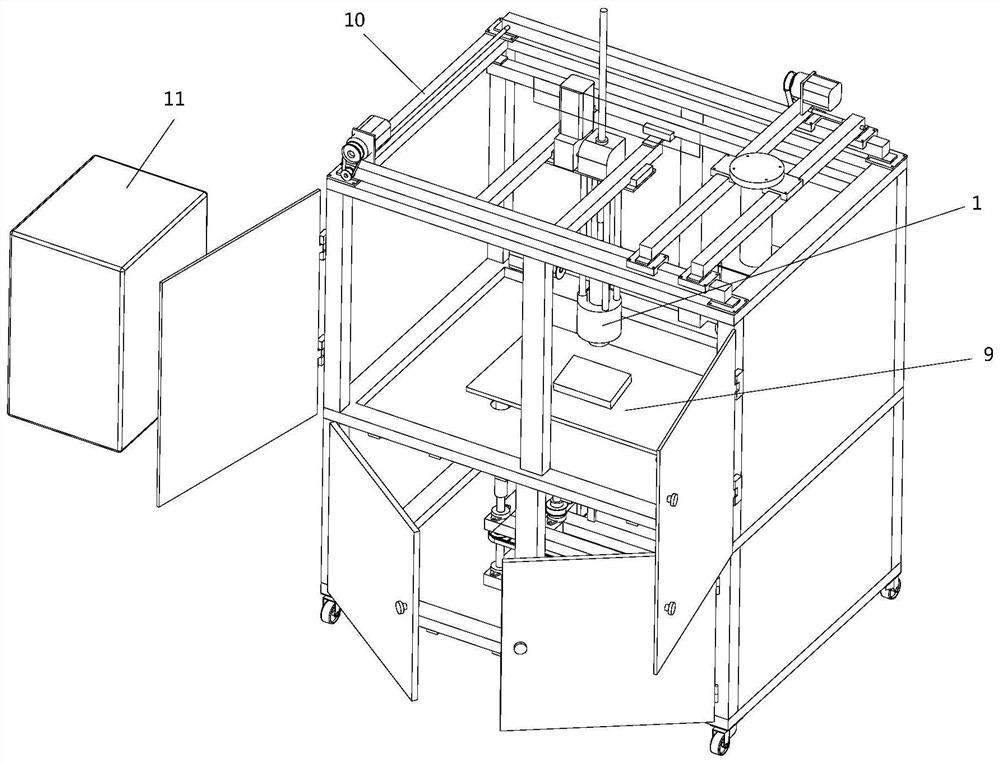

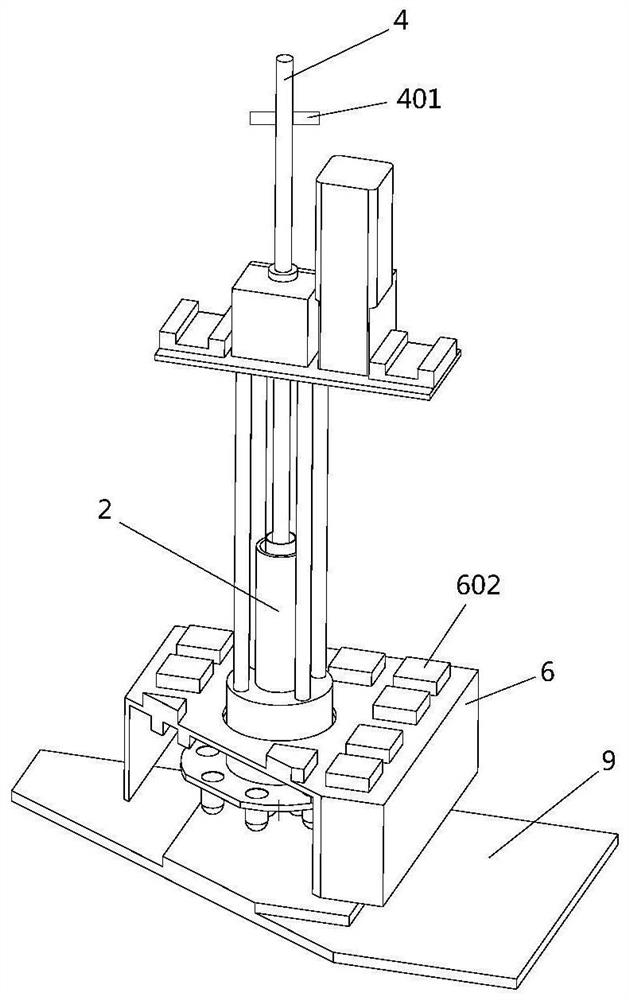

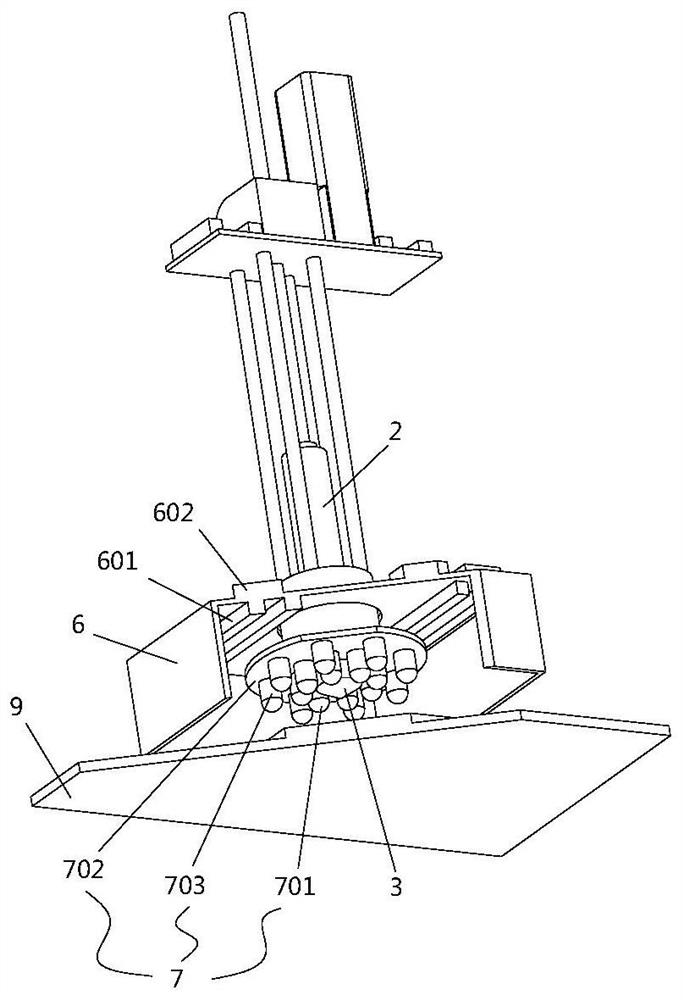

[0105] Such as Figure 1 to Figure 3 As shown, a rapid prototyping device 1 for ultra-high molecular weight polymers described in this embodiment includes a silo 2, and a nozzle 3 arranged at the bottom of the silo 2; a heating module 5 is formed from the silo From the top to the bottom of the nozzle 3 side, a heating zone where the temperature gradually increases; the feeding rod 4 cooperates with the feed bin, and reciprocates in the feed bin 2 along the axial direction of the feed rod 4; heating The cover 6 covers at least the shower head 3 and forms a heating chamber outside the shower head 3 .

[0106] Wherein, the trajectory of the heating mantle 6 is synchronized with the trajectory of the shower head 3; the heating mantle 6 is a heating chamber with a sealed peripheral wall and an opening at the bottom; the nozzle 3 extends from the top of the heating mantle 6 In the heating chamber; inside the top of the heating mantle 6, several heating parts 601 are arranged at int...

Embodiment 2

[0110] Such as Figure 1 to Figure 3 As shown, a rapid prototyping device 1 for ultra-high molecular weight polymers described in this embodiment includes a rolling assembly 7 for compacting the ultra-high molecular weight polymers extruded from the nozzle 3; the rolling The assembly 7 includes a first fixed seat 702, connected with the silo 2, and / or, the spray head 3; a second fixed seat 703, connected with the first fixed seat 702; a pressure roller 701, arranged on the Inside the second fixed seat 703; the pressure roller 701, by rolling on the surface of the ultra-high molecular weight polymer extruded by the nozzle 3, realizes the compaction of the ultra-high molecular weight polymer; the first fixed seat 702 is, The fixed structure that is connected to the silo 2 and / or the spray head 3 is arranged in a plane; the second fixed seat 703 is at least one cylindrical structure arranged on the first fixed seat 702 Hollow structure; the pressure roller 701 is a ball that can...

Embodiment 3

[0114] Such as Figure 1 to Figure 5 As shown, a rapid prototyping device 1 for ultra-high molecular weight polymers described in this embodiment includes a first feeding chamber 201, a second feeding chamber 202 and The cross-sectional area of the third feeding chamber 203 ; the first feeding chamber 201 , the second feeding chamber 202 and the third feeding chamber 203 along the radial direction of the silo 2 gradually decreases.

[0115] The first feeding chamber 201 is arranged inside the silo 2; at least two of the second feeding chambers 202 are arranged inside the silo 2 and communicated with the first feeding chamber 201; At least two of the third feeding chambers 203 are arranged inside the silo 2 and communicate with the second feeding chamber 202 .

[0116] Preferably, the first feeding chamber 201, the second feeding chamber 202 and the third feeding chamber 203 are cylindrical structures;

[0117] More preferably, the diameter of the first feeding cavity 201 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com