Nattokinase sustained-release microspheres and preparation method thereof

A technology of nattokinase and slow-release microspheres, applied in biochemical equipment and methods, enzymes, peptidases, etc., can solve the problem of low effective efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

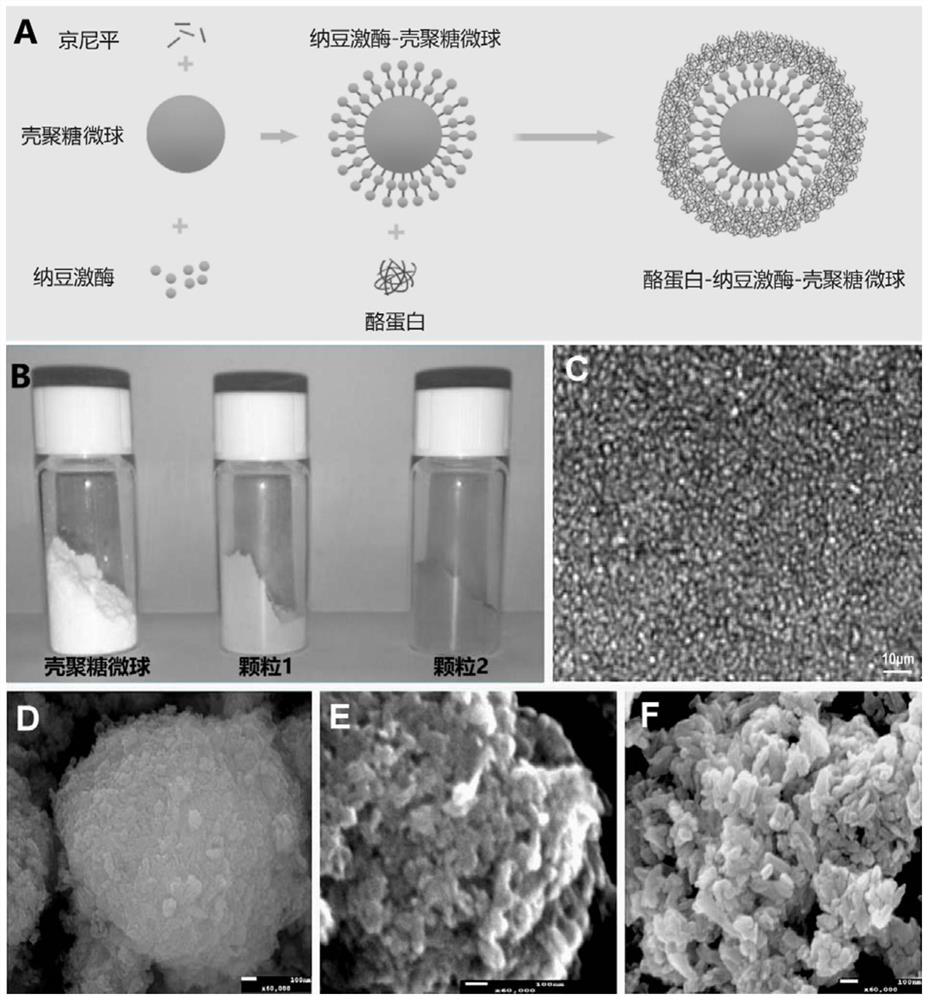

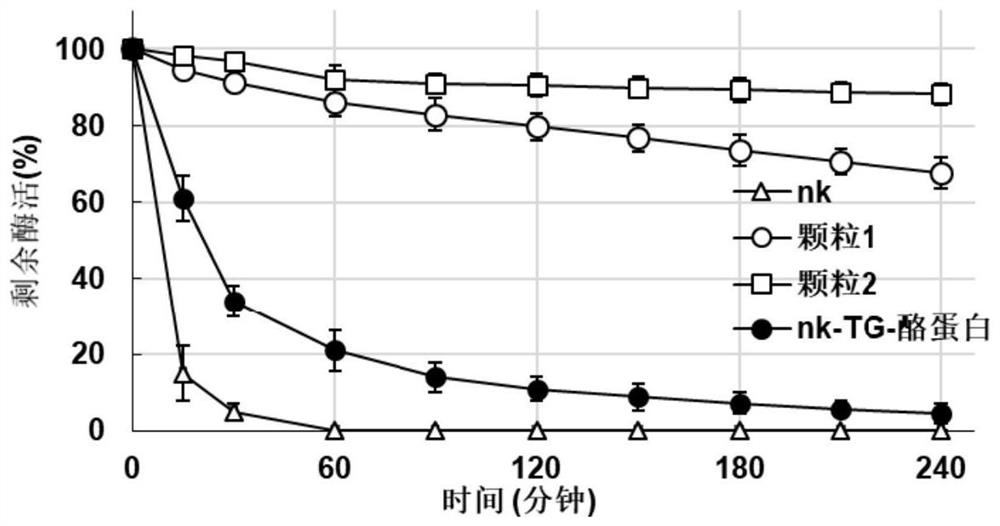

[0075] Embodiment 1: chitosan-nattokinase sustained-release microspheres

[0076] (1) Preparation of chitosan-nattokinase sustained-release microspheres

[0077] 1) The emulsifier and the organic solvent are mixed according to the volume ratio of emulsifier: organic solvent=1:50 to obtain an oil phase, wherein the emulsifier used is span-80, and the organic solvent used is liquid paraffin;

[0078] 2) Chitosan is added to an acetic acid solution with a volume concentration of 3%, magnetically stirred for 2 hours to make it fully dissolved, left to stand, and made into an aqueous phase with a mass concentration of chitosan of 0.5%;

[0079] 3) dissolving sodium tripolyphosphate in water to prepare crosslinking agent A with a concentration of sodium tripolyphosphate of 10 mg / ml;

[0080] 4) dissolving genipin in 30% ethanol solution to prepare a cross-linking agent B with a genipin concentration of 3 mg / ml;

[0081] 5) dispersing nattokinase in water to prepare an aqueous solu...

Embodiment 2

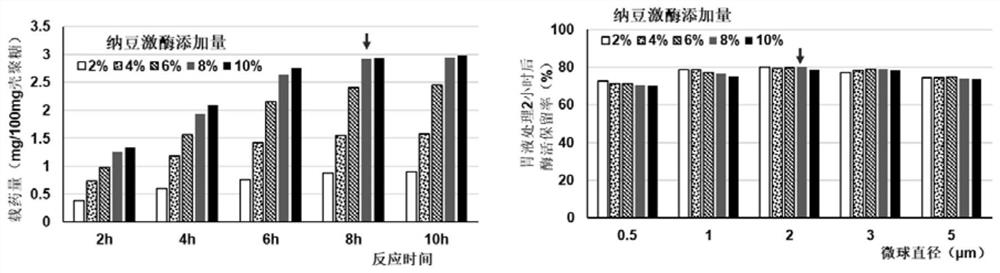

[0088] Optimization of Preparation Conditions of Chitosan-Nattokinase Sustained Release Microspheres

[0089] 1) The emulsifier and the organic solvent are mixed according to the volume ratio of emulsifier: organic solvent=1:50 to obtain an oil phase, wherein the emulsifier used is span-80, and the organic solvent used is liquid paraffin;

[0090] 2) Chitosan is added to an acetic acid solution with a volume concentration of 3%, magnetically stirred for 2 hours to make it fully dissolved, left to stand, and made into an aqueous phase with a chitosan mass concentration of 0.5%;

[0091] 3) dissolving sodium tripolyphosphate in water to prepare crosslinking agent A with a concentration of sodium tripolyphosphate of 10 mg / ml;

[0092] 4) dissolving genipin in 30% ethanol solution to prepare a cross-linking agent B with a genipin concentration of 3 mg / ml;

[0093] 5) dispersing nattokinase in water to prepare an aqueous solution with a concentration of 50 mg / ml;

[0094] 6) Acco...

Embodiment 3

[0100] Embodiment 3: the preparation of chitosan-nattokinase sustained-release microspheres

[0101] 1) The emulsifier and the organic solvent are mixed according to the volume ratio of emulsifier: organic solvent=1:50 to obtain an oil phase, wherein the emulsifier used is span-80, and the organic solvent used is liquid paraffin;

[0102] 2) Chitosan is added to an acetic acid solution with a volume concentration of 3%, magnetically stirred for 2 hours, fully dissolved, left to stand, and made into an aqueous phase with a chitosan mass concentration of 3%;

[0103] 3) dissolving sodium tripolyphosphate in water to prepare crosslinking agent A with a concentration of sodium tripolyphosphate of 30 mg / ml;

[0104] 4) dissolving genipin in 90% ethanol solution to prepare a cross-linking agent B with a genipin concentration of 10 mg / ml;

[0105] 5) dispersing nattokinase in water to prepare an aqueous solution with a concentration of 50 mg / ml;

[0106] 6) According to the volume ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com