Artificial dermis and preparation method and application thereof

An artificial and dermal technology, applied in medical science, prosthesis, etc., can solve the problems of difficulty in ensuring the uniformity of preparations, affecting the effect of wound repair, and sudden release concentration of preparations, so as to avoid concentration of release concentration and promote cell proliferation. Growth and migration, effect of uniform concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

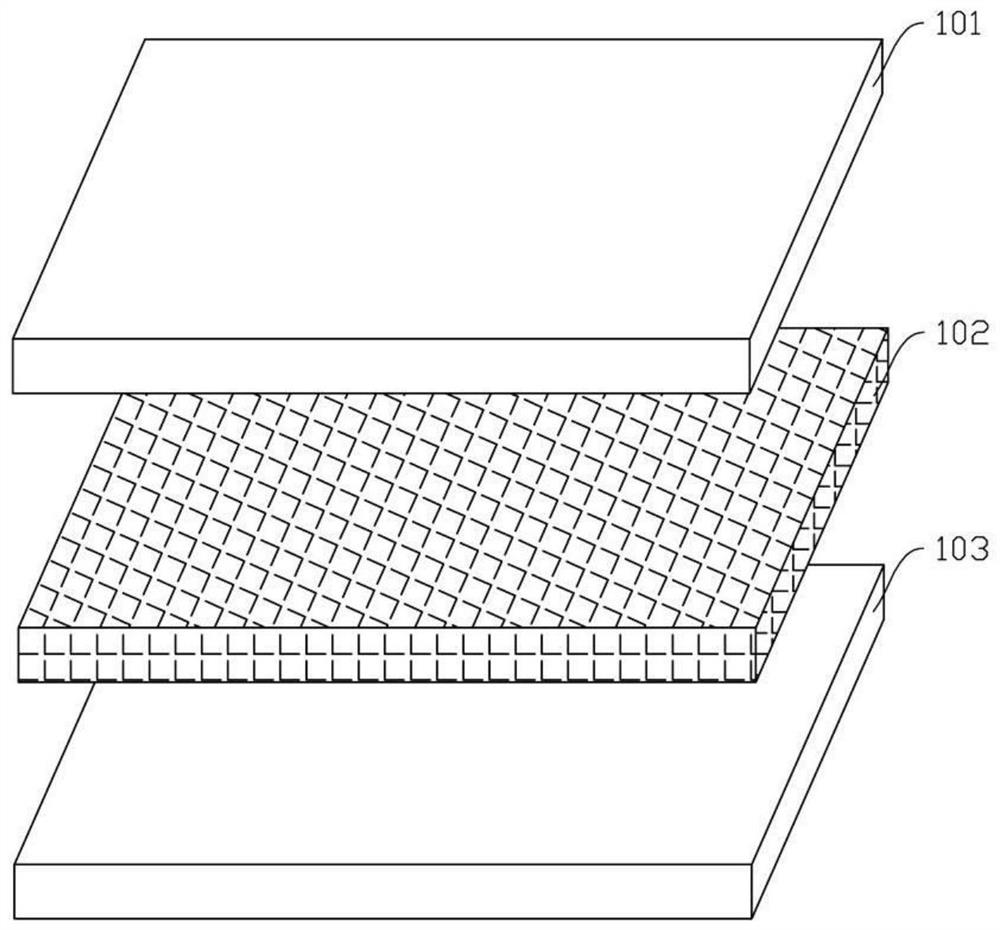

[0052] This embodiment provides a kind of artificial leather, such as figure 1 As shown, the artificial dermis includes a first collagen sponge layer 101 , a hydrogel biofilm layer 102 and a second collagen sponge layer 103 arranged in sequence. The first collagen sponge layer 101 and the second collagen sponge layer 103 are obtained by cross-linking collagen materials and chondroitin sulfate, and a certain amount of broad-spectrum antibacterial agent polyhexamethylene biguanide hydrochloride (PHMB) is mixed therein. The hydrogel biofilm layer 102 is a polycarboxymethyl chitosan-sodium alginate hydrogel scaffold doped with calcium polyphosphate particles. The particle diameter of the calcium polyphosphate particles is 100-300nm, and the repeating unit number of the phosphate group (Pi) is 40-100Pi. During the use of the artificial dermis, with the degradation of the hydrogel scaffold, the calcium polyphosphate particles are slowly released to the wound surface to provide meta...

Embodiment 2

[0060] This embodiment provides a method for preparing artificial dermis. The difference between this preparation method and Example 1 is that the components and contents of each step are different, as follows:

[0061] S1. Preparation of hydrogel biofilm: Weigh a certain amount of carboxymethyl chitosan into a small beaker, add deionized water and stir to dissolve to obtain a carboxymethyl chitosan aqueous solution with a concentration of 60 mg / mL. The same method was used to prepare a sodium polyphosphate aqueous solution with a concentration of 20 mg / mL and a gelatin aqueous solution with a concentration of 50 mg / mL. Take 5mL of sodium polyphosphate aqueous solution and add it into 10mL carboxymethyl chitosan aqueous solution through high-speed airflow atomization, and then add 15mL of MgCl with a concentration of 20mg / mL through high-speed airflow atomization 2 Aqueous solution, adjusted pH to 10 with 6M NaOH, stirred for 4h. Then, 10 mL of gelatin aqueous solution was ad...

Embodiment 3

[0066] This embodiment provides a method for preparing artificial dermis. The difference between this preparation method and Example 1 is that the components and contents of each step are different, as follows:

[0067] S1. Preparation of hydrogel biofilm: Weigh a certain amount of carboxymethyl chitosan into a small beaker, add deionized water and stir to dissolve to obtain a carboxymethyl chitosan aqueous solution with a concentration of 30 mg / mL. The same method was used to prepare a sodium polyphosphate aqueous solution with a concentration of 10 mg / mL and a sodium alginate aqueous solution with a concentration of 60 mg / mL. Take 5mL of sodium polyphosphate aqueous solution and add it into 10mL carboxymethyl chitosan aqueous solution through high-speed airflow atomization, and then add 15mL of CaCl with a concentration of 10mg / mL through high-speed airflow atomization 2 Aqueous solution, adjusted pH to 10 with 6M NaOH, stirred for 4h. Then, 10 ml of sodium alginate aqueous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com