Preparation method of porous semi-interpenetrating temperature-sensitive composite hydrogel

A composite hydrogel and semi-interpenetrating technology, which is applied in the direction of non-active ingredient medical preparations, pharmaceutical formulations, aerosol delivery, etc., can solve the problems of short release time, poor degradation performance, and difficulty in drug entry. Achieve good biocompatibility, high water content, and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

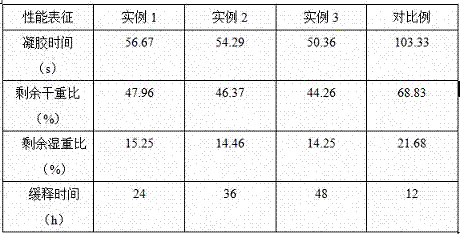

Examples

example 1

[0022] Take 20g of glucose, 3g of yeast extract, 15g of agar, and 5g of peptone, add them to 800mL of deionized water, stir at 300r / min for 20min, and adjust the pH to 5.0 with citric acid, then place them in an autoclave at 121°C, Sterilize for 20 minutes to obtain the fermentation medium, inoculate Acetobacter xylinum into 100 mL of fermentation medium according to the inoculum amount of 5% (V / V), cultivate it in a constant temperature incubator at 30°C for 8 days, and take out the surface of the fermentation medium with tweezers The resulting gel-like product was obtained as a bacterial cellulose hydrogel membrane. Soak the bacterial cellulose hydrogel membrane in 100mL of 0.1% sodium hydroxide solution in a constant temperature water bath at 70°C for 1 hour and then replace the hydrogen Repeat the soaking operation in sodium oxide solution 3 times, then soak and wash with deionized water until the washing liquid is neutral, and obtain purified bacterial cellulose gel. Take ...

example 2

[0024] Take 22g of glucose, 4g of yeast extract, 17g of agar, and 6g of peptone, add it to 900mL of deionized water, stir at 350r / min for 25min, and adjust the pH to 5.5 with citric acid, then place it in an autoclave at 123°C, Sterilize for 25 minutes to obtain the fermentation medium, inoculate Acetobacter xylinum into 110 mL of fermentation medium according to the inoculum amount of 6% (V / V), cultivate it in a constant temperature incubator at 31°C for 9 days, and take out the surface of the fermentation medium with tweezers The resulting gel-like product was obtained as a bacterial cellulose hydrogel membrane. Soak the bacterial cellulose hydrogel membrane in 150 mL of 0.1% sodium hydroxide solution in a constant temperature water bath at 75°C, soak for 1 hour, and then replace the hydrogen Repeat the soaking operation in sodium oxide solution 4 times, then soak and wash with deionized water until the washing liquid is neutral, and obtain purified bacterial cellulose gel. T...

example 3

[0026]Take 25g of glucose, 5g of yeast extract, 20g of agar, and 8g of peptone, add it to 1000mL of deionized water, stir at 400r / min for 30min, and adjust the pH to 6.0 with citric acid, then place it in an autoclave at 125°C, Sterilize for 30 minutes to obtain the fermentation medium, inoculate Acetobacter xylinum into 120 mL of fermentation medium according to the inoculum amount of 8% (V / V), culture it in a constant temperature incubator at 32°C for 10 days, and take out the surface of the fermentation medium with tweezers The resulting gel-like product was obtained as a bacterial cellulose hydrogel membrane. Soak the bacterial cellulose hydrogel membrane in 200mL of 0.1% sodium hydroxide solution in a constant temperature water bath at 80°C for 2 hours and then replace the hydrogen Repeat the soaking operation in sodium oxide solution 5 times, then soak and wash with deionized water until the washing liquid is neutral, and obtain purified bacterial cellulose gel. Take 14g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com