Preparation method of all-solid-state sulfide electrolyte for lithium ion battery

A technology for sulfide electrolytes and lithium-ion batteries, applied in the manufacture of electrolyte batteries, electrolytes, non-aqueous electrolyte batteries, etc., can solve problems such as hydrogen sulfide gas corrosion, electrode flatulence, etc., to inhibit corrosion, improve conductivity, and improve cycle performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

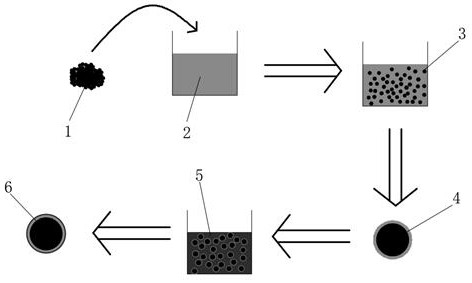

Method used

Image

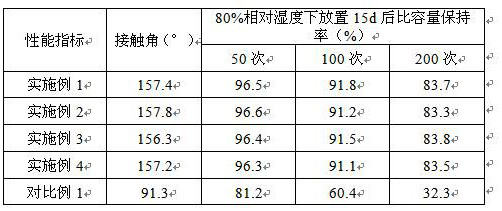

Examples

Embodiment 1

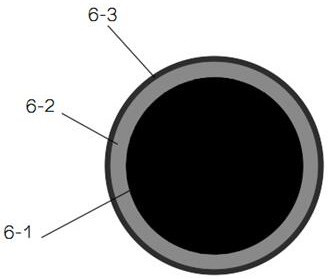

[0030] (1) Will Li 2 S, P 2 S 5 Mix with the doped powder evenly according to the stoichiometric ratio, then add it to the vacuum silicon tube, and use micro-arc oxidation discharge for heat treatment to obtain doped solid electrolyte powder; the metal elements of the doped powder are magnesium and germanium; doped solid electrolyte powder In the preparation of electrolyte particles, Li 2 S, P 2 S 5 , The molar ratio of the doped powder is 1:0.7:0.3; the output voltage of the micro-arc oxidation discharge is 580V, the temperature is 86°C, and the time is 56min;

[0031] (2) Mix the doped solid electrolyte particles with epoxy resin and nano-silica evenly, and then add a coupling agent for stirring, so that the epoxy resin is coupled with nano-silica to coat the particles, and the coating treatment is obtained. Doping solid electrolyte particles; the coupling agent is isopropyl titanate triisostearate; in the preparation of coated doped solid electrolyte particles, doping ...

Embodiment 2

[0038] (1) Will Li 2 S, P 2 S 5 Mix with the doping powder evenly according to the stoichiometric ratio, then add it to the vacuum silicon tube, and use micro-arc oxidation discharge for heat treatment to obtain the doped solid electrolyte powder; the metal elements of the doped powder are gallium and selenium; the doped solid electrolyte powder In the preparation of electrolyte particles, Li 2 S, P 2 S 5 , The molar ratio of the doped powder is 1:0.5:0.1; the output voltage of the micro-arc oxidation discharge is 500V, the temperature is 80°C, and the time is 60min;

[0039] (2) Mix the doped solid electrolyte particles with epoxy resin and nano-silica evenly, and then add a coupling agent for stirring, so that the epoxy resin is coupled with nano-silica to coat the particles, and the coating treatment is obtained. Doping solid electrolyte particles; the coupling agent is isopropyl tris(dioctyl phosphate acyloxy) titanate; in the preparation of coated doped solid electro...

Embodiment 3

[0044] (1) Will Li 2 S, P 2 S 5 Mix with the doping powder evenly according to the stoichiometric ratio, then add it into the vacuum silicon tube, and use micro-arc oxidation discharge for heat treatment to obtain the doped solid electrolyte powder; the metal elements of the doping powder are magnesium, selenium, titanium; In the preparation of heterosolid electrolyte particles, Li 2 S, P 2 S 5 , The molar ratio of the doped powder is 1:0.9:0.5; the output voltage of the micro-arc oxidation discharge is 700V, the temperature is 90°C, and the time is 50min;

[0045] (2) Mix the doped solid electrolyte particles with epoxy resin and nano-silica evenly, and then add a coupling agent for stirring, so that the epoxy resin is coupled with nano-silica to coat the particles, and the coating treatment is obtained. Doping solid electrolyte particles; the coupling agent is bis(dioctyloxypyrophosphate) ethylene titanate; in the preparation of coated doped solid electrolyte particles,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com