Manufacturing method for producing green microcrystalline glass plate by utilizing Pan long jade tailings

A technology of glass-ceramic and panlong jade, applied in glass forming, glass manufacturing equipment, glass furnace equipment, etc., can solve the problem of high production cost, and achieve the effect of saving energy cost, reducing energy consumption and reducing melting temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

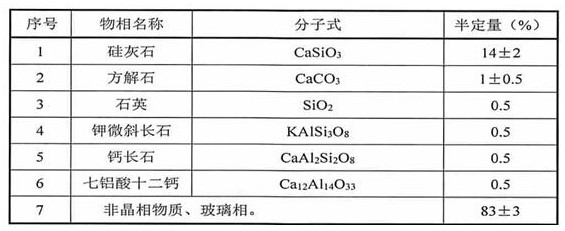

[0033] see figure 1 , the present invention provides a technical solution: a method for producing green glass-ceramic plates using Panlong jade tailings, comprising the following steps:

[0034] Step 1: Take 32-38 parts of Panlong jade tailings; 8-12 parts of feldspar; 18-25 parts of quartz sand; 6-10 parts of dolomite; 5-10 parts of calcite; 1-4 parts of sodium acid; 0-2 parts of borax; 4-10 parts of soda ash; 0.1-0.3 parts of stabilizer;

[0035] Step 2: Prepare a qualified mixture by weighing, stirring and mixing;

[0036] Step 3: Melt in a high-temperature furnace at 1480-1500°C for 4-6 hours. After melting, pour the molten glass into water, and quench it into glass pellets;

[0037] Step 4: Dry the glass granules, and sieve them through 8 mesh, 16 mesh, and 30 mesh, and spread the granules under 8-16-30 mesh respectively in refractory porcelain boats with a size of 80*30. Then put the porcelain boat in a box-type electric furnace for crystallization treatment, the crys...

Embodiment 2

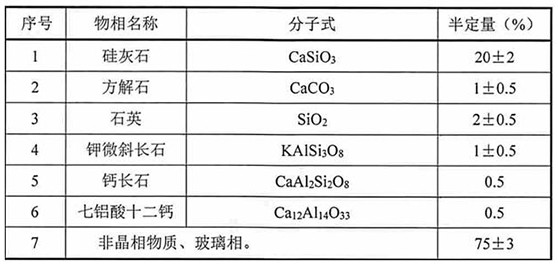

[0040] see figure 2 , the present invention provides a technical solution: a method for producing green glass-ceramic plates using Panlong jade tailings, comprising the following steps:

[0041] Step 1: Take 36 parts of Panlong jade tailings; 11 parts of feldspar; 21 parts of quartz sand; 8 parts of dolomite; 7 parts of calcite; 5 parts of barium carbonate; 2 parts of sodium dichromate; 2 parts of borax; 8 parts of soda ash ; 0.2 parts of stabilizer;

[0042] Step 2: Prepare a qualified mixture by weighing, stirring and mixing;

[0043] Step 3: Melt in a high-temperature furnace at 1480°C for 6 hours. After melting, pour the molten glass into water, and quench it into glass pellets;

[0044] Step 4: Dry the glass granules, and pass through 8 mesh and 16 mesh sieves, mix the 8 mesh and 16 mesh granules, weigh 700 grams of the material as the base material, and spread it on a 140*140 The bottom layer of the refractory sagger, and then use 8-16 mesh 300 grams of pellets as th...

Embodiment 3

[0047] see image 3 , the present invention provides a technical solution: a method for producing green glass-ceramic plates using Panlong jade tailings, comprising the following steps:

[0048] Step 1: Take 36 parts of Panlong jade tailings; 11 parts of feldspar; 21 parts of quartz sand; 8 parts of dolomite; 7 parts of calcite; 5 parts of barium carbonate; 2 parts of sodium dichromate; 2 parts of borax; 8 parts of soda ash ; 0.2 parts of stabilizer;

[0049] Step 2: Prepare a qualified mixture by weighing, stirring and mixing;

[0050] Step 3: Melt in a high-temperature furnace at 1480°C for 6 hours. After melting, pour the molten glass into water, and quench it into glass pellets;

[0051] Step 4: Dry the glass pellets, and pass through 8 mesh and 16 mesh sieve, mix the pellets above 8 mesh and below 16 mesh, weigh 7 kg as the base material, and lay it flat on a surface with a size of 530*410*19 The bottom layer of the refractory material mold, and then use 8-16 mesh 3 kg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com