Formula fertilizer special for ratoon rice

A technology for formula fertilizer and regenerated rice, applied in the field of fertilizers, can solve the problems affecting the safety of full heading and yield in the following regeneration season, incorrect use time of nitrogen fertilizer, and poor control of fertilization time, so as to reduce soil nutrient loss and adjust grades. Simple and easy, the effect of promoting fertilizer use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

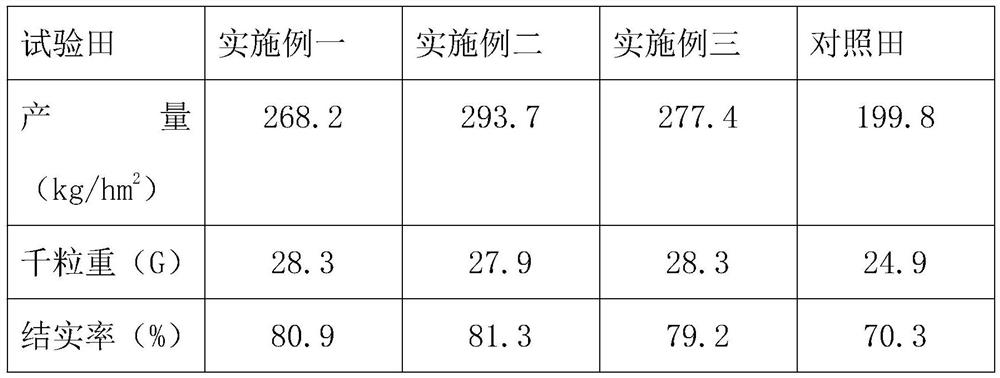

Examples

Embodiment 1

[0021] A kind of preparation method of special formula fertilizer for ratooning rice proposed by the present invention comprises the following steps,

[0022] Select the following raw materials in parts by weight: 200 parts of urea, 150 parts of potassium chloride, 100 parts of organic fertilizer, 20 parts of selenium ore powder, 40 parts of water-retaining agent, 100 parts of calcium peroxide, 40 parts of phosphorus pentoxide and 3 parts of fertilizer .

[0023] S1, grind the weighed granular raw materials such as urea and then dry them, pass through a sieve with a diameter of 5 mm after grinding, and obtain the raw material powder after screening;

[0024] S2, add the remaining raw materials to the raw material powder, and place them in the mixer to mix evenly, and the mixed powder is agglomerated and granulated by humidifying and heating in the tumbling bed through the granulator;

[0025] S3, the obtained granulated material is dried and cooled and then sieved. Those that...

Embodiment 2

[0027] A kind of preparation method of special formula fertilizer for ratooning rice proposed by the present invention comprises the following steps,

[0028] Select the following raw materials in parts by weight: 250 parts of urea, 200 parts of potassium chloride, 200 parts of organic fertilizer, 30 parts of selenium mineral powder, 55 parts of water-retaining agent, 150 parts of calcium peroxide, 60 parts of phosphorus pentoxide, 5 parts of fertilizer .

[0029] S1, grind the weighed granular raw materials such as urea and then dry them, pass through a sieve with a diameter of 5 mm after grinding, and obtain the raw material powder after screening;

[0030] S2, add the remaining raw materials to the raw material powder, and place them in the mixer to mix evenly, and the mixed powder is agglomerated and granulated by humidifying and heating in the tumbling bed through the granulator;

[0031] S3, the obtained granulated material is dried and cooled and then sieved. Those tha...

Embodiment 3

[0033] A kind of preparation method of special formula fertilizer for ratooning rice proposed by the present invention comprises the following steps,

[0034] Select the following raw materials in parts by weight: 220 parts of urea, 180 parts of potassium chloride, 150 parts of organic fertilizer, 25 parts of selenium ore powder, 48 parts of water-retaining agent, 125 parts of calcium peroxide, 45 parts of phosphorus pentoxide, 4 parts of fertilizer .

[0035] S1, grind the weighed granular raw materials such as urea and then dry them, pass through a sieve with a diameter of 5 mm after grinding, and obtain the raw material powder after screening;

[0036] S2, add the remaining raw materials to the raw material powder, and place them in the mixer to mix evenly, and the mixed powder is agglomerated and granulated by humidifying and heating in the tumbling bed through the granulator;

[0037] S3, the obtained granulated material is dried and cooled and then sieved. Those that me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com