Method for preparing silicon-carbon composite material by molten salt assisted magnesiothermic reduction

A technology of silicon-carbon composite materials and composite materials, applied in the direction of nanotechnology, active material electrodes, nanotechnology, etc. for materials and surface science, can solve the problems of complex process and high reduction temperature, so as to improve electronic conductivity and reduce Formation of silicon carbide, effect of alleviating volume expansion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) First, attapulgite was dried at 200 °C to remove water, washed with 4 mol / L HCl solution, and then 2 g of pretreated attapulgite was uniformly dispersed in 300 mL of ethanol-water mixed solution (V 乙醇 : V 水 = 1:4) to obtain attapulgite dispersion; dissolve 2 g of sodium alginate in 100 ml of deionized water to form a sodium alginate solution; mix the attapulgite dispersion and sodium alginate solution, stir dry, and place under inert gas protection and carbonization at 800 °C for 5 h to obtain an amorphous carbon coating-coated attapulgite composite material.

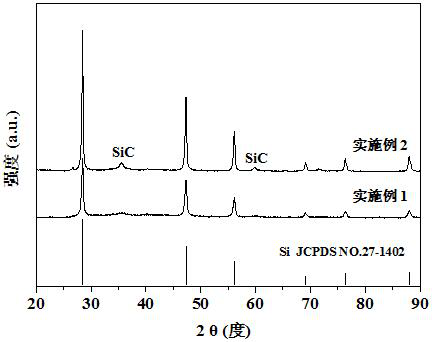

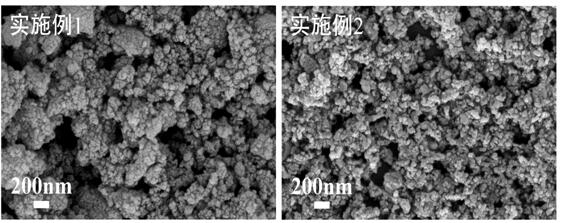

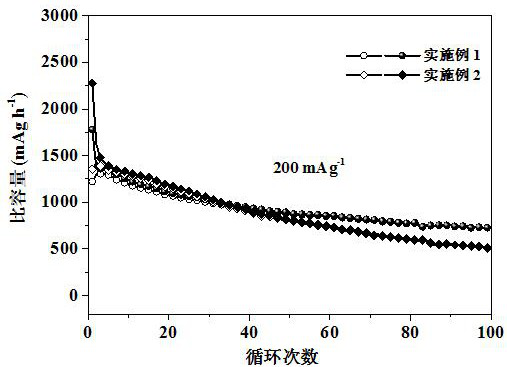

[0024] (2) Mix the amorphous carbon coating-coated attapulgite composite material with magnesium powder in a mass ratio of 1:1, and mix and grind it with potassium chloride in a mass ratio of 1:15, and react at 650 ° C under the protection of inert gas. 5h, cooled to room temperature, then washed with hydrochloric acid and hydrofluoric acid, and finally washed with deionized water and absolute ethanol, and d...

Embodiment 2

[0027] (1) First, attapulgite was dried at 300 °C to remove water, washed with 8 mol / L HCl solution, and then 4 g of pretreated attapulgite was uniformly dispersed in 300 mL of ethanol-water mixed solution (V 乙醇 : V 水 = 1:4) to obtain attapulgite dispersion; dissolve 2 g of potassium alginate in 100 ml of deionized water to form a potassium alginate solution; mix the attapulgite dispersion and potassium alginate solution, stir dry, and place under inert gas protection and carbonization at 900 °C for 2 h to obtain an amorphous carbon coating-coated attapulgite composite material.

[0028] (2) Mix the amorphous carbon coating-coated attapulgite composite material with magnesium powder in a mass ratio of 1:3, and mix and grind it with potassium chloride in a mass ratio of 1:25, and react at 750 ° C under the protection of inert gas. 6h, cooled to room temperature, then washed with hydrochloric acid and hydrofluoric acid, and finally washed with deionized water and absolute ethan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Reversible specific capacity | aaaaa | aaaaa |

| Coulombic efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com