Heavy aromatics lightening catalyst as well as preparation method and application thereof

A technology for lightening heavy aromatics and catalysts. It is applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc. It can solve the problems of difficult separation of nano-zeolite, low production efficiency, and increased cost, and achieve good regeneration performance. , the effect of long reaction cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

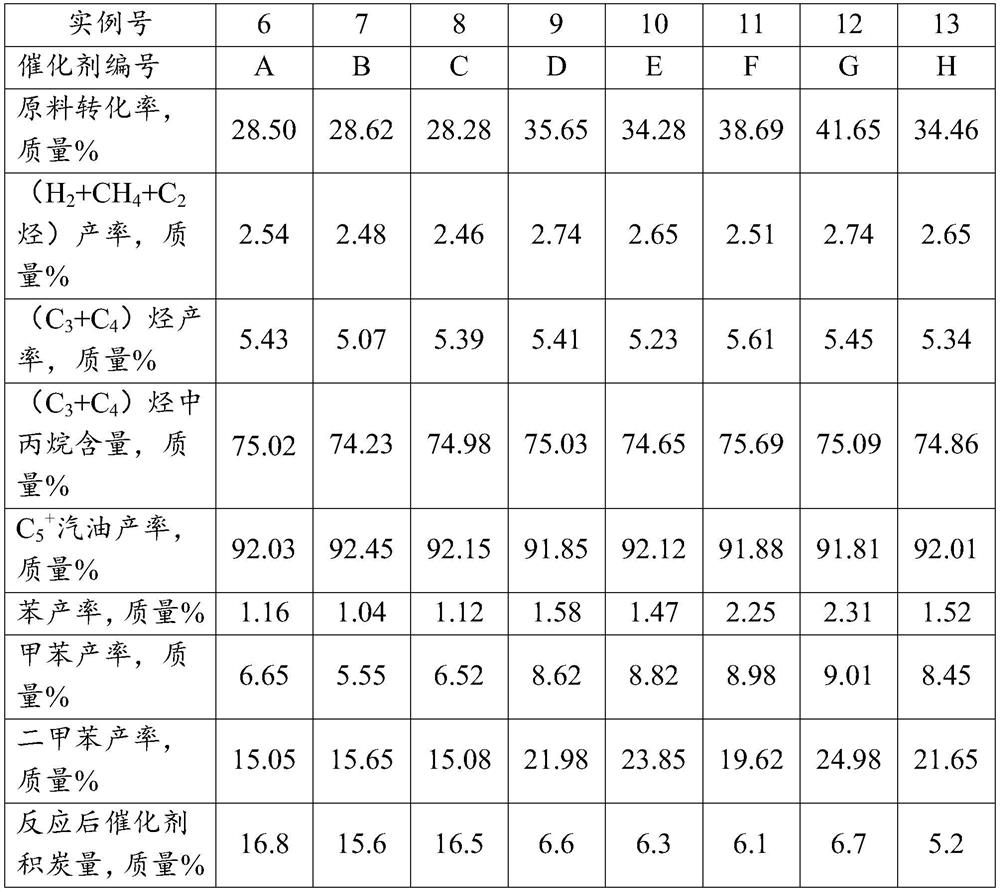

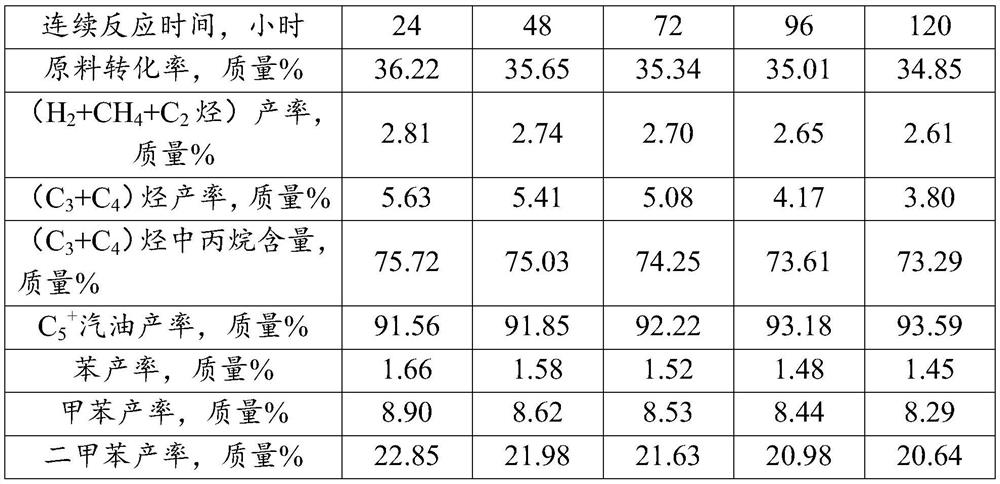

Examples

preparation example Construction

[0019] Preferably, the preparation method of the catalyst of the present invention comprises the steps of:

[0020] (1) Pseudo-boehmite and acid solution are fully mixed and then peptized to obtain an aluminum sol with an alumina content of 8-16% by mass, adding hydrogen-type ZSM-5 and hydrogen-type EU-1 zeolite, and stirring evenly to obtain an aluminum sol containing The zeolite slurry is formed by dropping balls in an oil ammonia column, and the wet balls formed by the drop balls are dried at 30-100°C for 5-30 hours, activated at 500-650°C for 2-6 hours, and a spherical composite carrier is obtained.

[0021] (2) impregnating the spherical composite carrier prepared in step (1) with a compound solution containing VA group elements, drying and roasting at 500-700° C. to obtain a spherical catalyst, and then treating it with water vapor at 400-600° C. for 0.5-8 hours.

[0022] The step (1) of the above method is to prepare a small spherical composite carrier, and the mass rat...

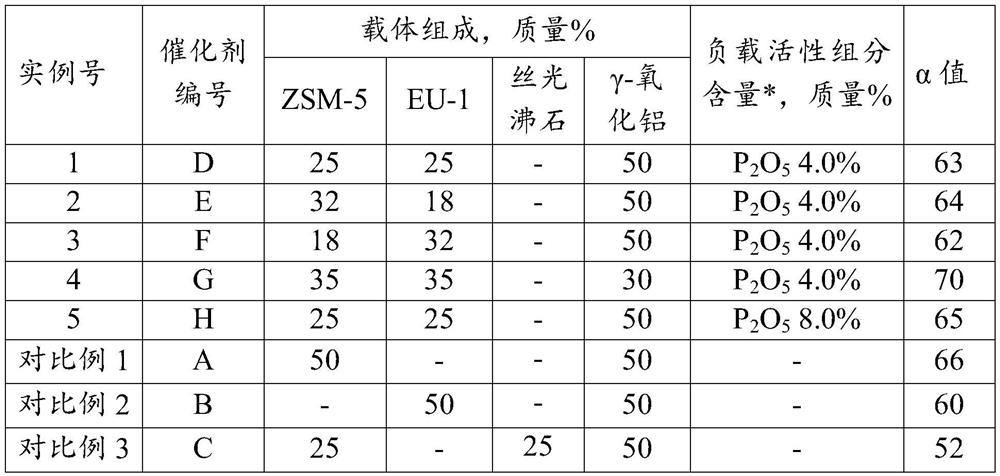

example 1

[0038] The following examples prepare the catalyst of the present invention

[0039] (1) Preparation of small spherical composite carrier

[0040] Get 67.6 grams of pseudo-boehmite (produced by Sasol company, SB powder, the alumina content is 75% by mass), under stirring conditions, adding 270 grams of nitric acid aqueous solution with a concentration of 1.1% by mass, after peptizing for 2 hours, to obtain an aluminum sol with an alumina content of 10% by mass, adding 25 g SiO 2 / Al 2 o 3 Hydrogen ZSM-5 molecular sieve with a molar ratio of 50 and 25 grams of SiO 2 / Al 2 o 3 The hydrogen EU-1 molecular sieve with a molar ratio of 60 was stirred at a high speed for 3 hours to obtain a zeolite-containing slurry, and the solid content in the slurry was 20% by mass.

[0041] The above slurry was formed into drop balls in an oil ammonia column, the temperature of the drop ball was 15°C, the oil phase of the oil ammonia column was kerosene with a thickness of 10 cm, the thic...

example 2

[0045] Catalyst is prepared by the method of example 1, difference is (1) the hydrogen type ZSM-5 molecular sieve that adds in the aluminum sol is 32 grams, the hydrogen type EU-1 molecular sieve that adds is 18 grams, obtains that solid content is 20 mass % The zeolite-containing slurry was dropped, dried, and roasted to obtain a composite carrier e, which contained 32% by mass of hydrogen-type ZSM-5 molecular sieve, 18% by mass of hydrogen-type EU-1 molecular sieve and 50% by mass of γ-oxidized aluminum. The composition and α value of the catalyst E obtained after impregnating the composite carrier e with phosphoric acid solution, drying, calcining and water vapor treatment are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com