Polystyrene-divinyl benzene modified magnetic carbon nanotube composite material and application thereof

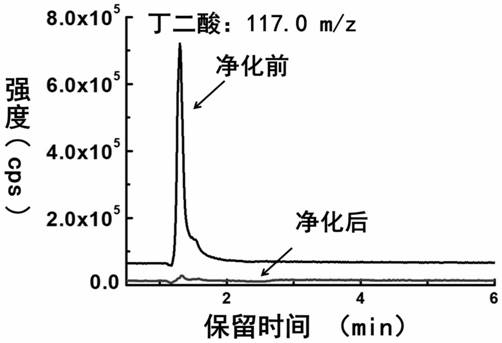

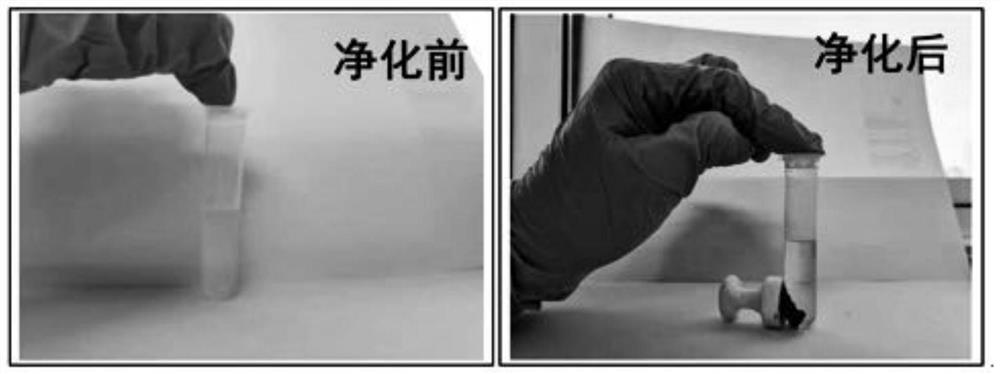

A technology of magnetic carbon nanotubes and divinylbenzene, which is applied in the analysis of materials, material separation, and other chemical processes, can solve the problems of unsatisfactory purification effects and achieve the effect of reducing the matrix effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

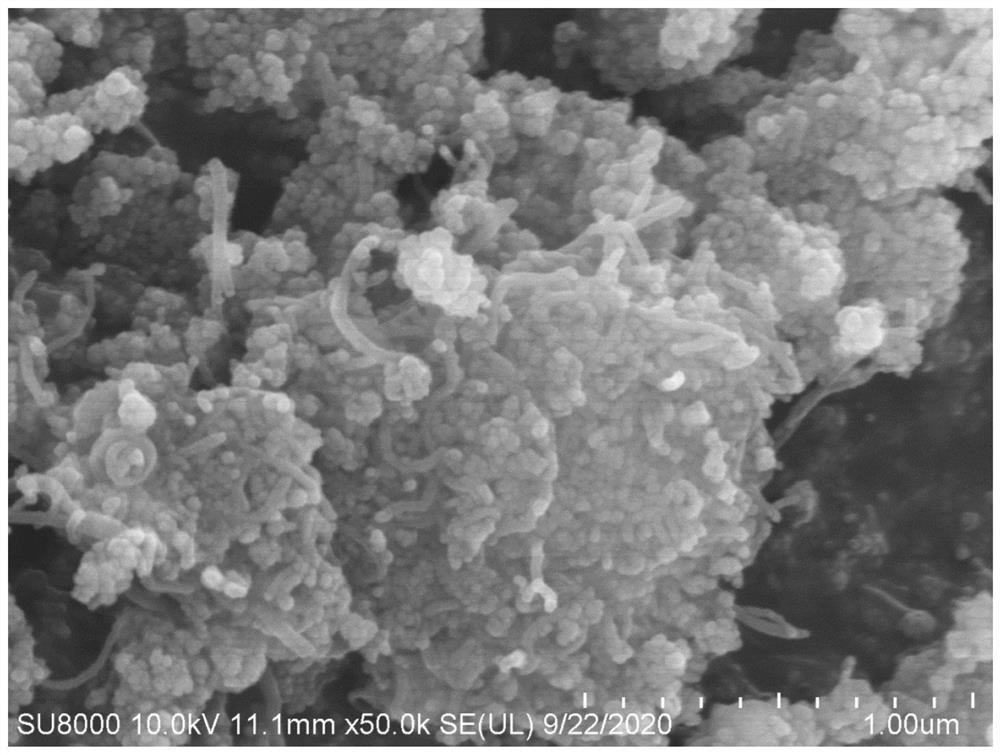

[0032]A method of synthesizing magnetic carbon nanotube composites modified by polystyrene-divinylbenzene, including the following steps:

[0033]Step 1, synthesized magnetic multi-walled carbon nanotube matrix;

[0034]Preparation of poly (styrene-divinylbenzene) modified magnetic multi-walled carbon nanotubes (Fe3O4MWCNTS @ P (ST-CO-DVB)).

[0035]Step 1.1, prepared magnetic multi-walled carbon nanotubes using coprecipitation method: 5 g of iron chloride and 5 g of ferrous sulfate in 100 ml of deionized water;

[0036]Step 1.2, 2 g of multi-wall carbon nanotubes were dispersed in the above solution, and 120 mL of 28% WT ammonia solution was added dropwise, the reaction liquid was heated to 70 ° C, and the reaction was continued under stirring.

[0037]Step 1.3, the prepared black product sequentially uses deionized water, ethanol, to remove the unreacted residue, after treatment, the product Fe3O4MWCNTS was placed at a vacuum drying box for 12 hours of vacuum drying in a 60 ° C.

[0038]Step 2, mod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com