Two-component polyurethane coating as well as preparation method and application thereof

A two-component polyurethane and coating technology, applied in the coating field, can solve the problems of poor insulation performance, slow cross-linking reaction rate, and inability to apply electrical insulation materials, etc., to achieve good adhesion, good dimensional stability, and prevent leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

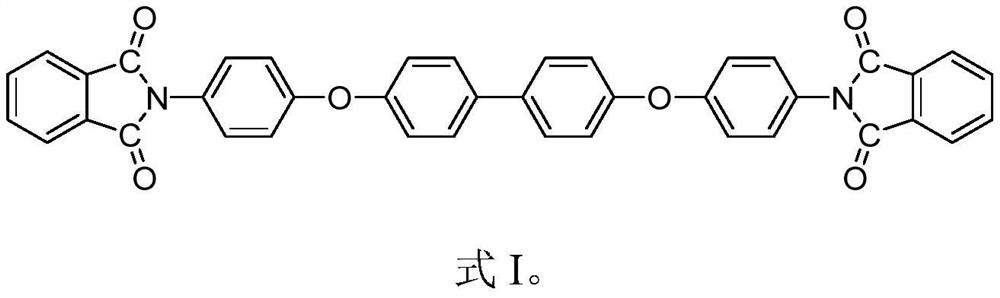

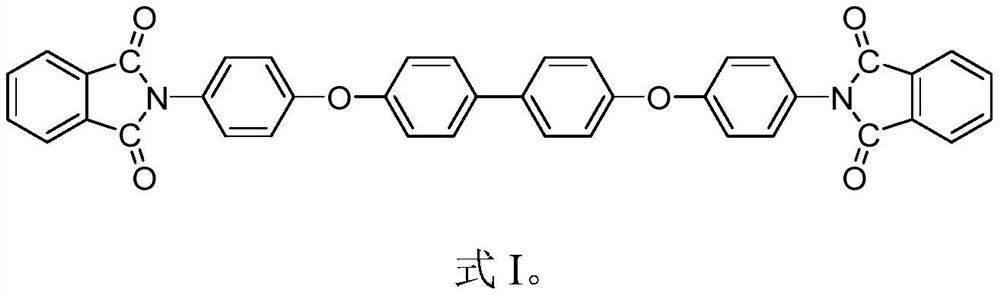

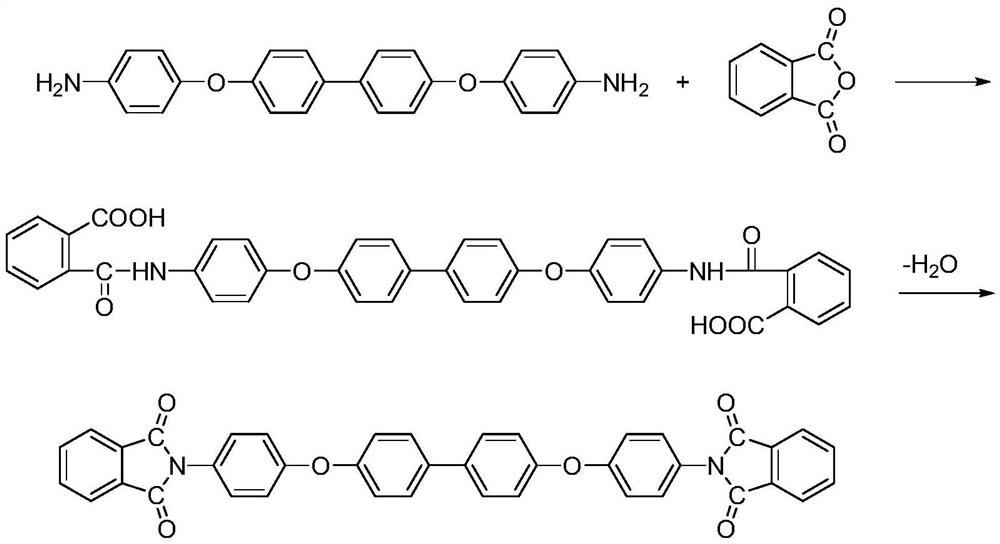

[0061] The local preparation example provides the polyimide represented by Formula I, and the polyimide shown in Formula I is prepared from the following preparation method: 4,4'-di (4-aminophenoxy) biphenyl (0.1 mol, 36.8 g) was dissolved in DMF (200 mL), and phthalic anhydride (0.2 mol, 29.6 g) was added, and the mixture was mixed, then toluene mixed, 10 ° C was heated and refluxed for 4 h, separated from benzene The solvent and DMF were allowed to cool after crystalline crystalline (5.86 g, purity 98%, yield 92.3% yield).

[0062] The sources of each component are as follows: isocyanate is purchased in (manufacturers: Dugguai Chemical Co., Ltd., brand IPDI), super branched polyol purchase (manufacturer: Perstorp, brand Boltorn H20), catalyst purchase ( Manufacturer: Shanghai Nanxiang Reagent Co., Ltd., brand DBTDL Company, brand MDEA), pigment purchases in (manufacturers: Anhui black color new materials, cards HY330), UV light absorbers are purchased in (manufacturers: Yongluo,...

Embodiment 1

[0064] This embodiment provides a two-component polyurethane coating comprising a component and a component B component, the composition of the A component and the B component is shown below, wherein a component and group B The weight ratio of points is 1: 2:

[0065]

[0066] The preparation method includes the step of mixing an isocyanate, a polyol, a catalyst, and a storage stabilizer in the preparation of the A component, and the reaction is heated at 80 ° C for 3 h at 80 ° C to obtain a prepolymer containing an end isocyanate group. Further, stirring with polyimide at 80 ° C to obtain the A component; a polyol, crosslinking agent, pigment, ultraviolet absorber, auxiliary agent, a pigment, an ultraviolet absorber and aid in the preparation of B components in the formulation. The mixture was mixed at ° C to give the B component.

Embodiment 2

[0068] This embodiment provides a two-component polyurethane coating comprising a component and a component B component, the composition of the A component and the B component is shown below, wherein a component and group B The weight ratio of points is 1: 2:

[0069]

[0070] The preparation method includes the step of mixing an isocyanate, a polyol, a catalyst, and a storage stabilizer in the preparation of the A component, and the reaction is heated at 80 ° C for 3 h at 80 ° C to obtain a prepolymer containing an end isocyanate group. Further, stirring with polyimide at 80 ° C to obtain the A component; a polyol, crosslinking agent, pigment, ultraviolet absorber, auxiliary agent, a pigment, an ultraviolet absorber and aid in the preparation of B components in the formulation. The mixture was mixed at ° C to give the B component.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com