Sulfur precipitant, desulfurization system and application thereof

A precipitant and sulfur technology, applied in the field of desulfurization, can solve the problems of sulfur floating up and desulfurization system not running smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] In the present invention, the preparation method of the sulfur precipitating agent preferably includes the following steps: mixing the N-acyl amino acid type surfactant and water, mixing the polyethylene glycol type nonionic surfactant and / or organosilicon surfactant Dissolve in low-carbon alcohol, and then mix the two liquid phases to obtain the sulfur precipitant.

[0036] The present invention does not specifically limit the specific manner of dissolving and mixing, and methods well known to those skilled in the art can be used.

[0037] The present invention also provides a desulfurization system, which includes a desulfurization agent packed separately and the sulfur precipitation agent described in the above scheme; the composition of the desulfurization agent includes a desulfurization catalyst, a stabilizer, alkali and water.

[0038] In the present invention, the desulfurization catalyst is preferably a complex iron compound, specifically iron nitrilotriacetate...

Embodiment 1

[0047] (1) Preparation of sulfur precipitant: Utilize isopropanol, sodium lauroyl sarcosinate, laurylphenol polyoxyethylene ether and water to prepare sulfur precipitant. The preparation method is: mix sodium lauroyl sarcosinate and water Mixing, dissolving dodecylphenol polyoxyethylene ether in isopropanol, and then mixing the two liquid phases to obtain a sulfur precipitant. Wherein the consumption of each component is shown in Table 1.

[0048] (2) Preparation of desulfurizer: Utilize ferric ammonium sulfate, NTA-3Na (trisodium aminotriacetate), sodium gluconate, sodium hydroxide and water to prepare desulfurizer, preparation method is: ferric ammonium sulfate, NTA-3Na and Sodium gluconate is dissolved in water, and then sodium hydroxide is added to adjust the pH value of the solution to 8-9 to obtain a desulfurizer. The dosage of each component is shown in Table 2, and the sulfur capacity of the desulfurization liquid prepared according to the composition table is 3.0g / L....

Embodiment 2

[0062] Chuanke 1 well pilot test device, the gas flow rate is 3000 m3 / d (hydrogen sulfide content is 0.859%), the sulfur output is 30kg / d, and it is operated continuously for 15 days to investigate the influence of sulfur precipitant on sulfur.

[0063] 150g of sodium lauroyl sarcosinate and water are mixed, 15g of polyoxyethylene dodecylphenol ether is dissolved in 15g of isopropanol, and then the two liquid phases are mixed to obtain a total surfactant mass fraction of 16.5% 1L of sulfur precipitant.

[0064] The prepared sulfur precipitant is continuously added to the desulfurization system with a total iron content of 10g / L, wherein the composition of the desulfurizer is consistent with that of Example 1, and the amount of the sulfur precipitant is controlled at 15-20mg / L. Settlement status and blockage of the device pipeline.

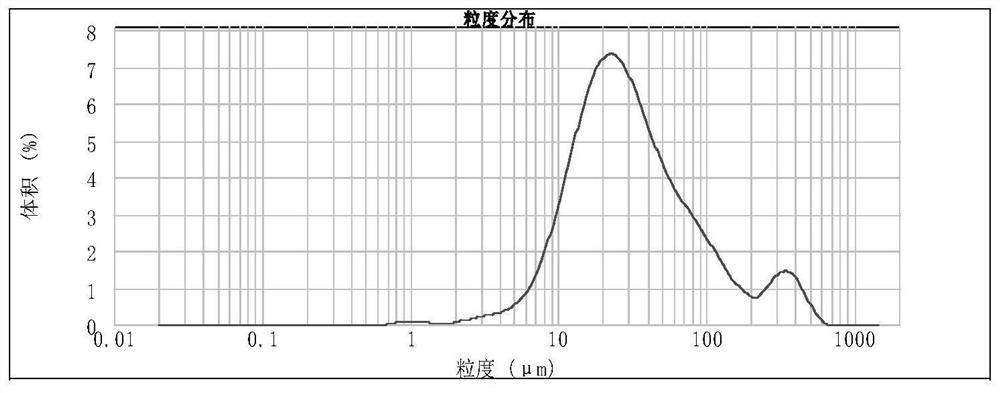

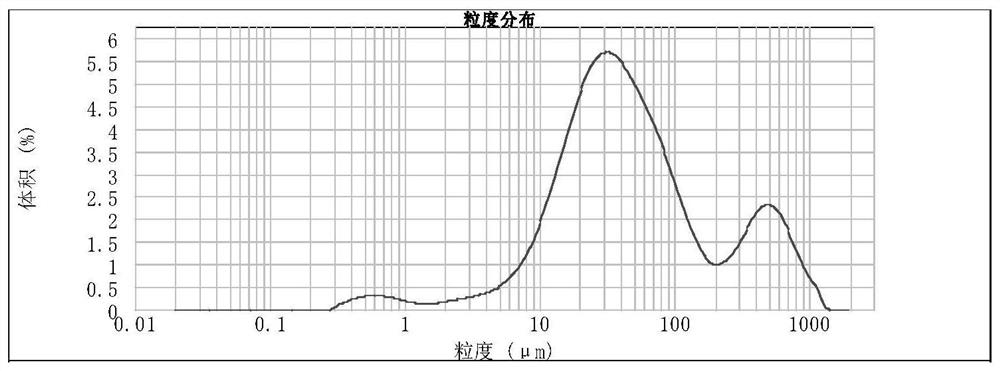

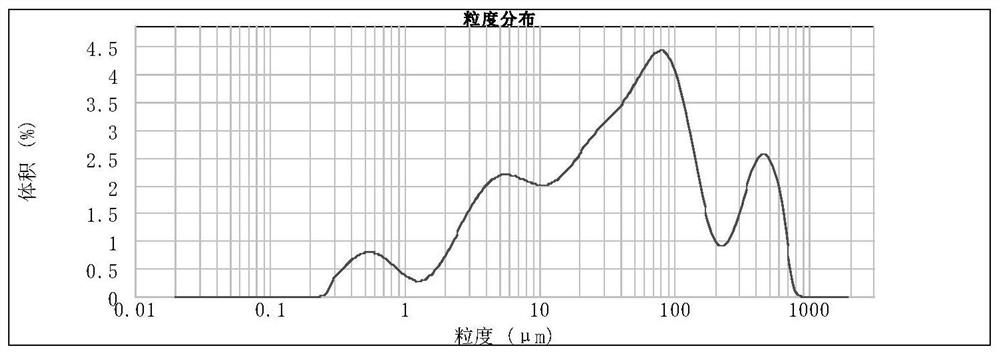

[0065] Observation results such as Figure 6 as shown, Figure 6 The left side is the desulfurization solution after the sulfur in the system i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com