Method for preparing hexanediol through whole-cell catalysis of genetically engineered bacteria

A technology of genetically engineered bacteria and whole-cell catalysts, applied in genetic engineering, microorganism-based methods, biochemical equipment and methods, etc., can solve the problems of product contamination, harsh reaction conditions, soaring prices of HDO-related products, etc., and achieve production efficiency. High and low use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

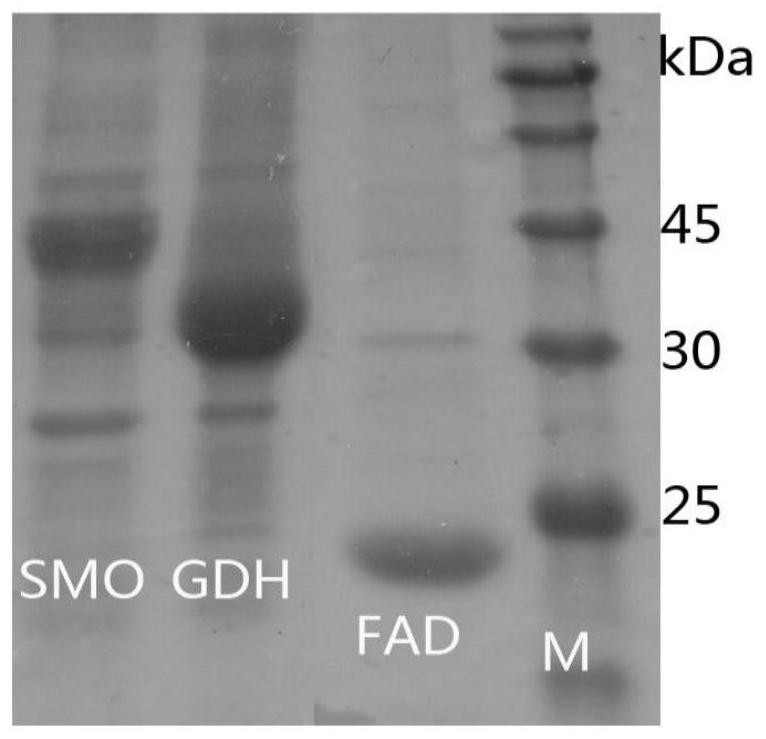

[0038] Embodiment 1 A kind of method for preparing the genetically engineered bacteria of SMO enzyme

[0039] Primers were designed according to the sequence of the SMO gene of Pseudomonas putida:

[0040] Forward primer: GGGAATTCCATATGatgaaaaagcgtatcggtattgttg, the underlined sequence is the enzyme cutting site NdeI.

[0041] Reverse primer: CGAGCTCggccgcaatagtgggtgcgtactggct, the underlined sequence is the SacI restriction site. The sequence number of the gene product is ABX24519.1.

[0042] The two ends of the gene sequence obtained by PCR have NdeI and SacI sites, and the gene is inserted into the pET30a vector, and the high-expression genetic engineering vector plasmid obtained is named pET30SMO, and then the high-expression vector is transformed into the recipient strain Escherichia coli In BL21(DE3), a genetically engineered bacterium with high SMO enzyme production was obtained, and the protein expressed by the obtained genetically engineered bacterium had a His-Tag ...

Embodiment 2

[0052] Embodiment 2 A kind of method for preparing the genetically engineered bacteria of FAD enzyme

[0053] Primers were designed according to the sequence of the FAD gene of Pseudomonas putida:

[0054] Forward primer: GGGAATTCCATATGgtgattcaaatgacgttaaaaaa, the underlined sequence is the enzyme cutting site NdeI.

[0055] Reverse primer: CGAGCTCattcagcggcaacgggttgccgtgataac, the underlined sequence is the SacI restriction site. The sequence number of the gene product is ABX24520.1.

[0056] The two ends of the gene sequence obtained by PCR have NdeI and SacI sites, and the gene is inserted into the pET30a vector, and the high-expression genetic engineering vector plasmid obtained is named pET30FAD, and then the high-expression vector is transformed into the recipient strain Escherichia coli In BL21(DE3), a genetically engineered bacterium with high FAD enzyme production was obtained, and the protein expressed by the obtained genetically engineered bacterium had a His-Tag ...

Embodiment 3

[0062] Embodiment 3 A kind of method for preparing the genetically engineered bacteria of GDH enzyme

[0063] Primers were designed according to the sequence of the GDH gene of Bacillus megaterium:

[0064] Forward primer: GGGAATTCCATATGATGTATACAGATTTAAAAGATAA, the underlined sequence is the enzyme cutting site NdeI.

[0065] Reverse primer: CGAGCTCGCCTCTTCCTGCTTGGAAA, the underlined sequence is the SacI restriction site. The sequence number of the gene product is AJI21421.1.

[0066] The two ends of the gene sequence obtained by PCR have NdeI and SacI sites, and the gene is inserted into the pET30a vector, and the high-expression genetic engineering vector plasmid obtained is named pET30GDH, and then the high-expression vector is transformed into the recipient strain Escherichia coli In BL21(DE3), a genetically engineered bacterium with high FAD enzyme production was obtained, and the protein expressed by the obtained genetically engineered bacterium had a His-Tag tag prote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com