Molecular sieve-based antibacterial additive for automobile leather as well as preparation method and application thereof

An antibacterial additive and molecular sieve technology, applied in the field of antibacterial materials, can solve the problems of incomplete antibacterial function, poor antibacterial effect, and low antibacterial life, and achieve the effect of simple and easy preparation method, large specific surface area, and improved mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

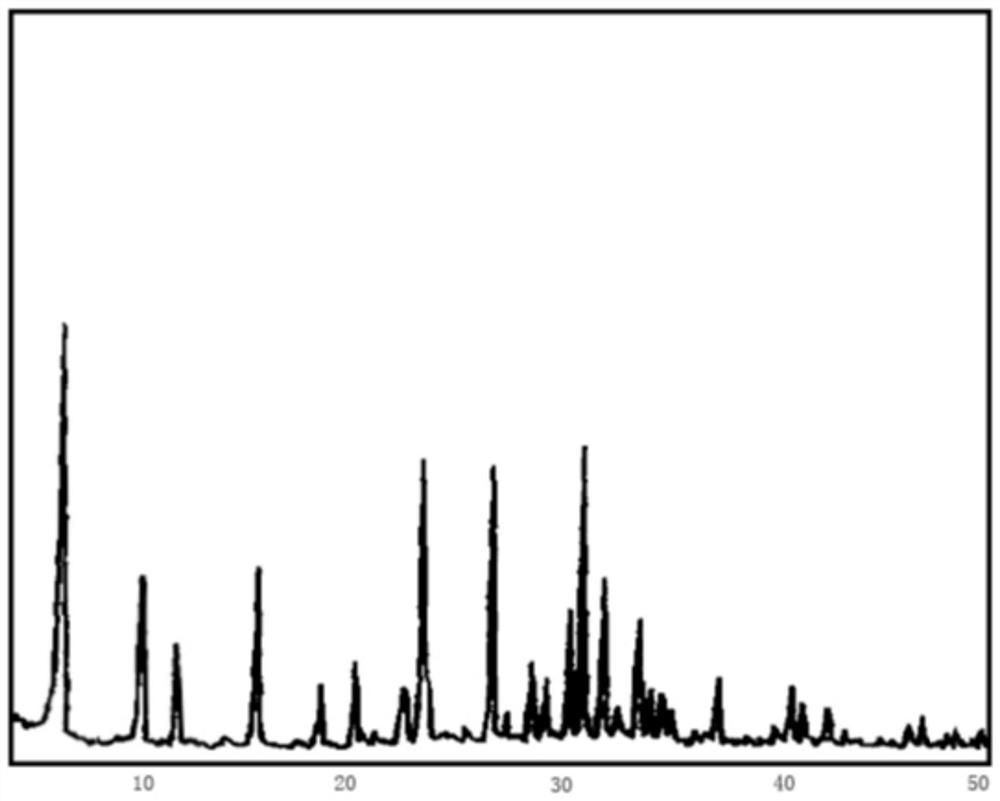

Image

Examples

Embodiment 1

[0050] The present embodiment provides a molecular sieve-based antibacterial additive for automobile leather, and its preparation method is as follows:

[0051] (1) Mix sodium metaaluminate, sodium hydroxide, sodium silicate, and water in the following molar ratio: SiO 2 / Al 2 o 3 = 3; Na 2 O / SiO 2 =1.5;H 2 O / Na 2 O=35, get the sol after mixing evenly;

[0052] (2) The sol was left to stand at 25°C for 3h, put into a polytetrafluoroethylene-lined stainless steel reaction kettle, and left at 98°C for 5h to obtain a crude product;

[0053] (3) The crude product is washed with deionized water, filtered, and dried to obtain a 13X molecular sieve material;

[0054] (4) According to the mass ratio, add 40 parts of 13X molecular sieve material to 300 parts of water to disperse, add 0.5 parts of copper acetate at the same time, add aqueous sodium hydroxide solution drop by drop, adjust pH = 10, stir well, heat to 70 ° C for 20 minutes, cool to At 20°C, a suspension was obtaine...

Embodiment 2

[0059] The present embodiment provides a molecular sieve-based antibacterial additive for automobile leather, and its preparation method is as follows:

[0060] (1) Mix sodium metaaluminate, sodium hydroxide, sodium silicate, and water in the following molar ratio: SiO 2 / Al 2 o 3 =5;Na 2 O / SiO 2 = 1; H 2 O / Na 2 O=35, get the sol after mixing evenly;

[0061] (2) The sol was left to stand at 25°C for 3h, put into a polytetrafluoroethylene-lined stainless steel reaction kettle, and stood at 96°C for 14h to obtain a crude product;

[0062] (3) The crude product is washed with deionized water, filtered, and dried to obtain a 13X molecular sieve material;

[0063] (4) According to the mass ratio, add 40 parts of 13X molecular sieve material to 300 parts of water to disperse, add 2 parts of copper acetate at the same time, add aqueous sodium hydroxide solution drop by drop, adjust pH = 9.5, stir well, heat to 65 ° C for 30 min, cool to At 20°C, a suspension was obtained;

...

Embodiment 3

[0068] The present embodiment provides a molecular sieve-based antibacterial additive for automobile leather, and its preparation method is as follows:

[0069] (1) Mix sodium metaaluminate, sodium hydroxide, sodium silicate, and water in the following molar ratio: SiO 2 / Al 2 o 3 = 4; Na 2 O / SiO 2 =1.3;H 2 O / Na 2 O=50, get the sol after mixing evenly;

[0070] (2) The sol was left to stand at 25°C for 5h, put into a polytetrafluoroethylene-lined stainless steel reaction kettle, and stood at 100°C for 9h to obtain a crude product;

[0071] (3) The crude product is washed with deionized water, filtered, and dried to obtain a 13X molecular sieve material;

[0072] (4) According to the mass ratio, add 40 parts of 13X molecular sieve material to 300 parts of water to disperse, add 3 parts of copper acetate at the same time, add aqueous sodium hydroxide solution drop by drop, adjust pH = 10.5, stir well, heat to 75 ° C for 15 minutes, cool to At 20°C, a suspension was obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com