Antibacterial and antiviral non-woven fabric and preparation method thereof

A non-woven, anti-viral technology, used in non-woven fabrics, rayon manufacturing, textiles and papermaking, etc., can solve the problem that cannot meet actual needs, and the antibacterial and antiviral properties have not been greatly improved. Single mechanism and other problems, to achieve the effect of excellent oxidizing ability, enhancing optical properties and oxidizing ability, and excellent antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

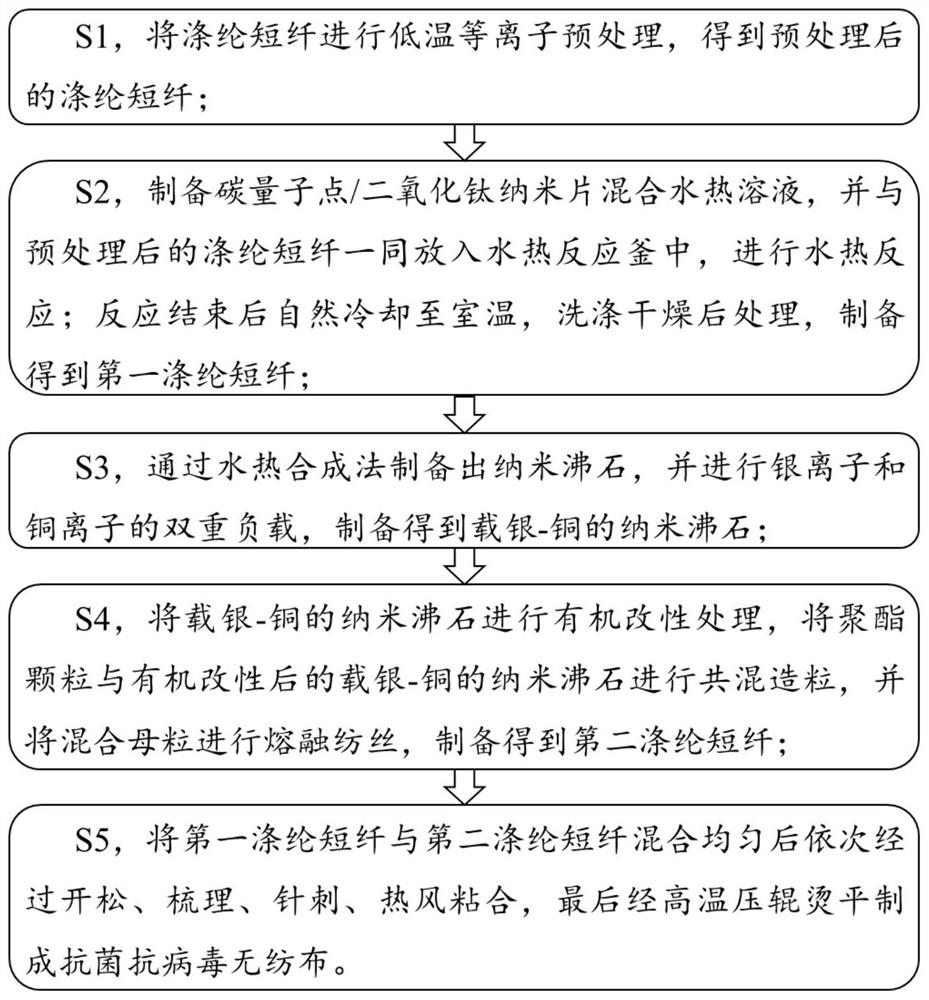

[0032] see figure 1 Shown, the invention provides a kind of preparation method of antibacterial antiviral nonwoven fabric, comprises the steps:

[0033] S1, polyester staple fiber pretreatment: low-temperature plasma pretreatment is performed on polyester staple fiber to obtain pretreated polyester staple fiber;

[0034] S2, preparation of the first polyester staple fiber: prepare a carbon quantum dot solution with a predetermined concentration, then add titanium dioxide nanosheets and stir evenly to obtain a hydrothermal solution, put the hydrothermal solution and the pretreated polyester staple fiber together into a hydrothermal reaction kettle, and the pretreated polyester staple fiber is completely submerged in the hydrothermal solution for hydrothermal reaction; after the reaction is finished, it is naturally cooled to room temperature, and the reacted polyester staple fiber is taken out and After washing and drying, the polyester staple fiber loaded with carbon quantum do...

Embodiment 1

[0046] A preparation method for an antibacterial and antiviral nonwoven fabric, comprising the steps of:

[0047] S1, polyester staple fiber pretreatment: the polyester staple fiber is treated with low-temperature plasma for 5 minutes in a room temperature air medium with a discharge power of 100W and a discharge voltage of 25Pa to obtain pretreated polyester staple fiber;

[0048] S2, preparation of the first polyester staple fiber: prepare 100 mL of carbon quantum dot solution with a concentration of 0.4 mg / mL, then add 0.7 g of two-dimensional titanium dioxide nanosheets and stir evenly to obtain a hydrothermal solution, and mix the hydrothermal solution with 50 g of the Put the pretreated polyester staple fibers together into a hydrothermal reaction kettle, and completely immerse the pretreated polyester staple fibers in the hydrothermal solution, and perform a hydrothermal reaction at 100° C. for 4 hours; the reaction ends After natural cooling to room temperature, the po...

Embodiment 2-4

[0066] The difference from Example 1 lies in that the parameter settings in the preparation process are different, and other steps are the same as in Example 1, and will not be repeated here.

[0067] Table 2 is the parameter setting of embodiment 1 to 4

[0068]

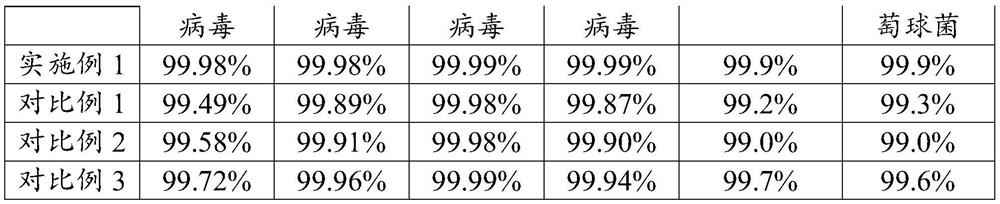

[0069] The antibacterial and antiviral performance test results of the antibacterial and antiviral non-woven fabric prepared by the above-mentioned embodiment are shown in the following table: (note: the tests are all carried out under ordinary light conditions)

[0070] Table 3 is the performance parameter data of embodiment 1 to 4

[0071]

[0072] As can be seen from Table 3, in the present invention, the loading of titanium dioxide nanosheets, the loading of nano zeolite of silver-copper and the mixing ratio of the first polyester staple fiber and the second polyester staple fiber will all affect the composite nonwoven fabric prepared by the present invention. Antibacterial and antiviral properties have a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com