Fuel oil saving device

A fuel oil and heating device technology, which is applied in the direction of fuel heat treatment device, charging system, liquid fuel feeder, etc., can solve the problems of poor energy saving effect, poor fuel saving efficiency, and short service life, so as to promote fuel saving Effect of use, improvement of treatment effect, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

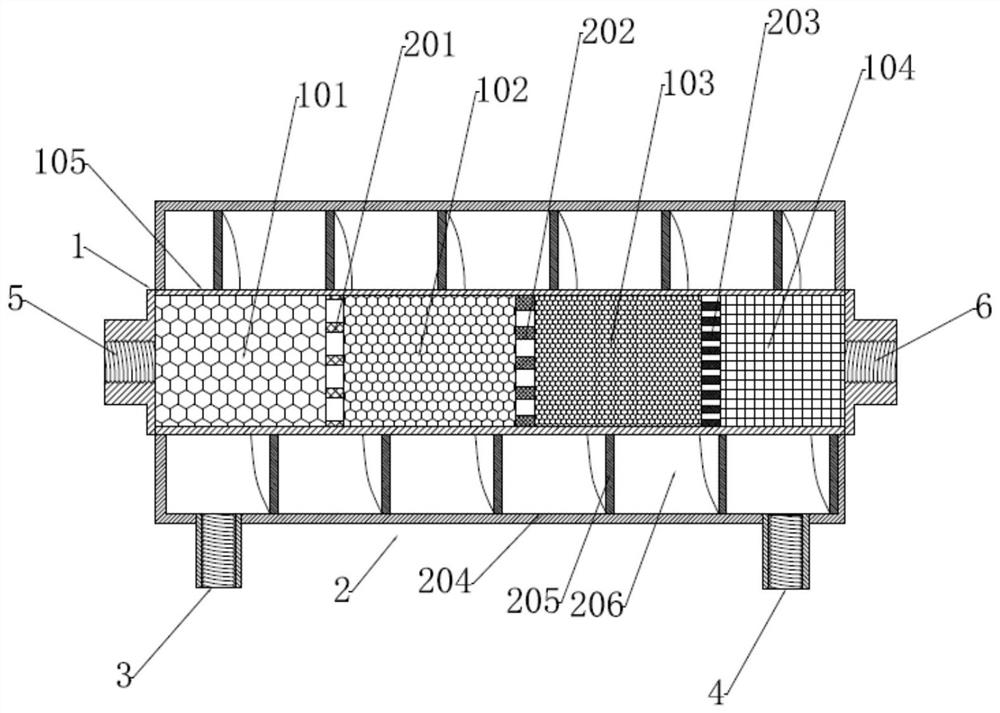

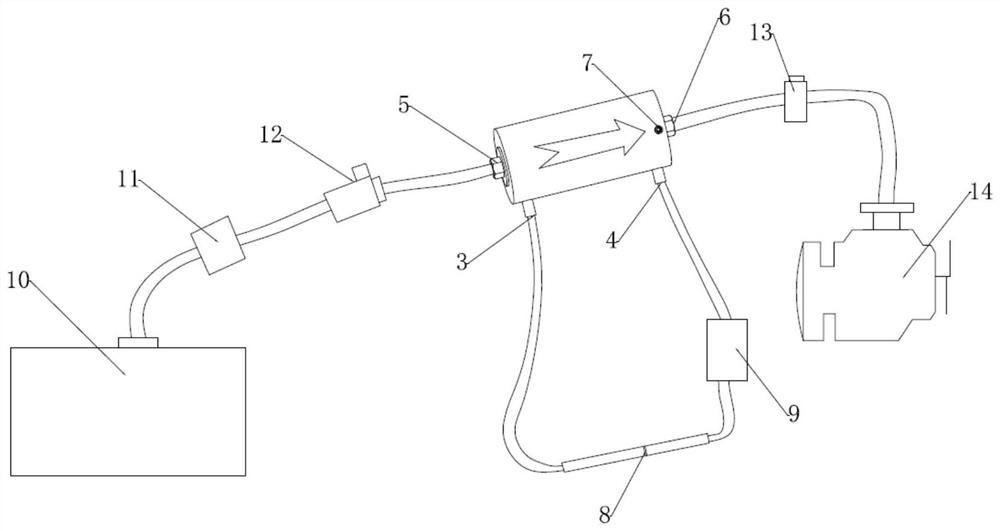

[0031] Example 1, such as figure 1 with image 3 as shown,

[0032] The present invention can improve the quality of oil products through the treatment of fuel oil by three filter materials and the filtering effect of three filter screens; and the molecular chain of combustion oil is changed from 300 μm to 3 μm by the molecular chain treatment device, and the molecules are rearranged, Change the air content in the fuel, improve the quality of the fuel, and meet the requirements of fuel-saving use; in addition, by setting the heating device to stimulate the molecular activity of the fuel, strengthen the role of the filter material and the molecular chain processing device, greatly improve the treatment effect, and indirectly promote the fuel oil. Fuel-saving effect.

Embodiment 2

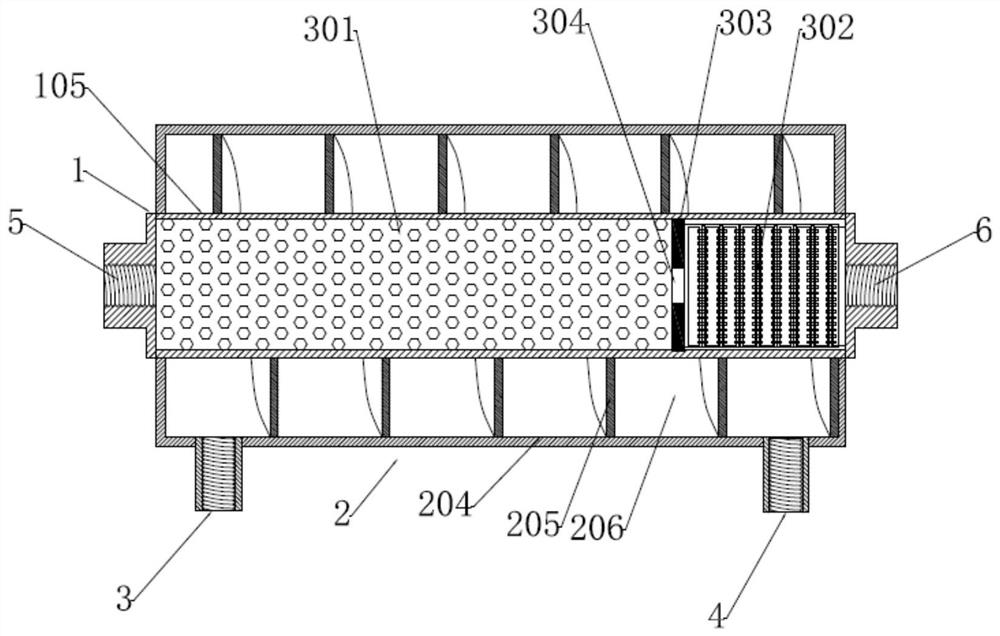

[0033] Example 2, such as figure 2 with image 3 as shown,

[0034] The energy ball is made of composite processing of natural tourmaline, zeolite, silicon oxide, calcium oxide and other materials, and is fired through a high-temperature calcination process above 1100°C.

[0035] The energy sheet is made of various mineral materials such as tourmaline, titanium oxide, zirconium oxide, and kaolin, and is fired through a high-temperature calcination process at 800°C.

[0036] Working principle: The fuel-saving device of the present invention, on the one hand, utilizes high-energy photon waves, electronic waves and magnetic energy. After being immersed in oil, it will emit high-energy waves unique to its own physical characteristics, and can generate electron separation, thereby It can emit a large number of α-rays and β-rays, and through the vibration of the amplitude, the fuel (gas) molecules can be promoted to form a resonance, the internal energy of the fuel (gas) molecule...

Embodiment

[0039]Example: The logistics vehicle of a certain company in Dongguan is equipped with a fuel-saving device with a heating device, and the fuel consumption of the logistics vehicle is calculated based on the first refueling.

[0040] Fuel consumption test on October 4, 2020: The vehicle showed 164190Km before driving, and 600L was refueled on October 4, 2020. After running, the displayed mileage was 148732km, that is, 1542km was driven with 600L fuel, and the fuel consumption per kilometer: 0.389L / km;

[0041] On October 8, 2020, I refueled 445L for the second time. After driving, the mileage displayed was 150274km, that is, I drove 1542km with 445L fuel, and the fuel consumption per kilometer: 0.28886L / km;

[0042] According to 100km fuel consumption calculation:

[0043] 38.9-28.86 = 10.04;

[0044] 10.04 / 38.9 = 25.8%.

[0045] According to the calculation, the fuel saving rate of the fuel has reached 25.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com