Preparation method of semiconductor material, perovskite semiconductor device and preparation method of perovskite semiconductor device

A semiconductor and perovskite technology, applied in the field of semiconductor optoelectronics, can solve the problems of low solar cell efficiency, large interface impedance, and many interface defects, and achieve the effects of increased charge collection efficiency, increased contact area, and good interface energy level matching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This embodiment provides a MAPbI 3 The preparation method of perovskite semiconductor material is prepared according to the following steps:

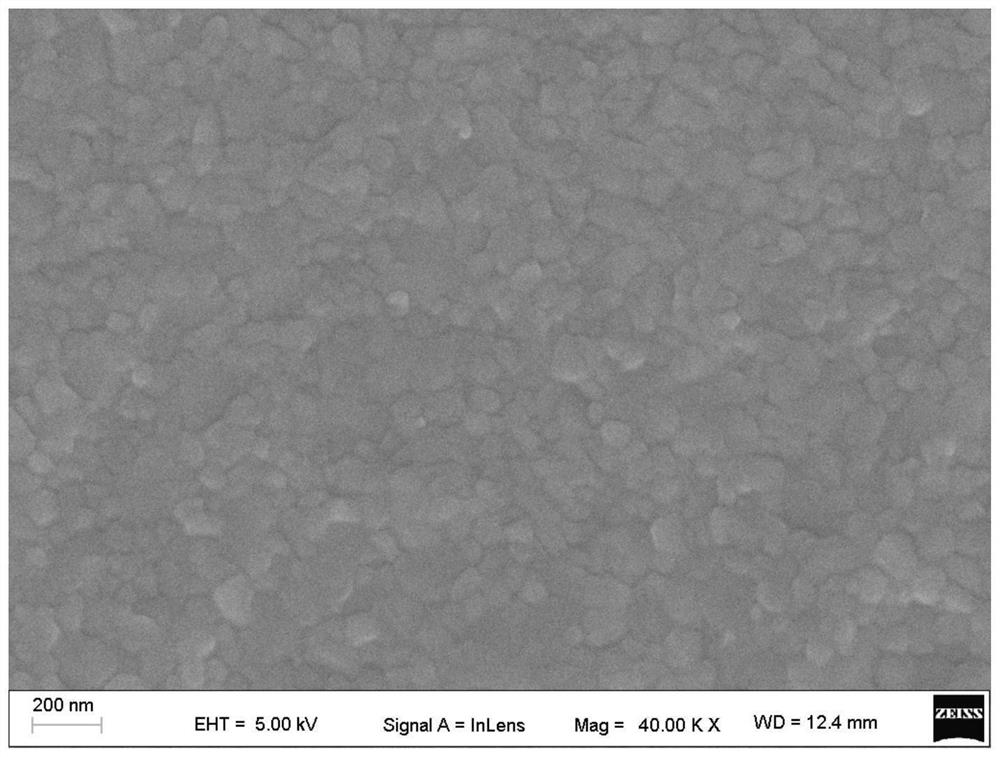

[0040] Take 60mg / mL lead acetate solution, the solvent is acetic acid, spin-coat at 2000rpm for 30 seconds on a common glass substrate, and then spin-coat 30mg / mL MAI (methylamine hydroiodide) solution, the solvent is isopropanol , spin-coating at 2000 rpm for 30 seconds, and heated at 100 °C for 10 minutes to obtain dense and smooth MAPbI 3 Perovskite thin films with surface microstructures such as figure 1 shown.

Embodiment 2

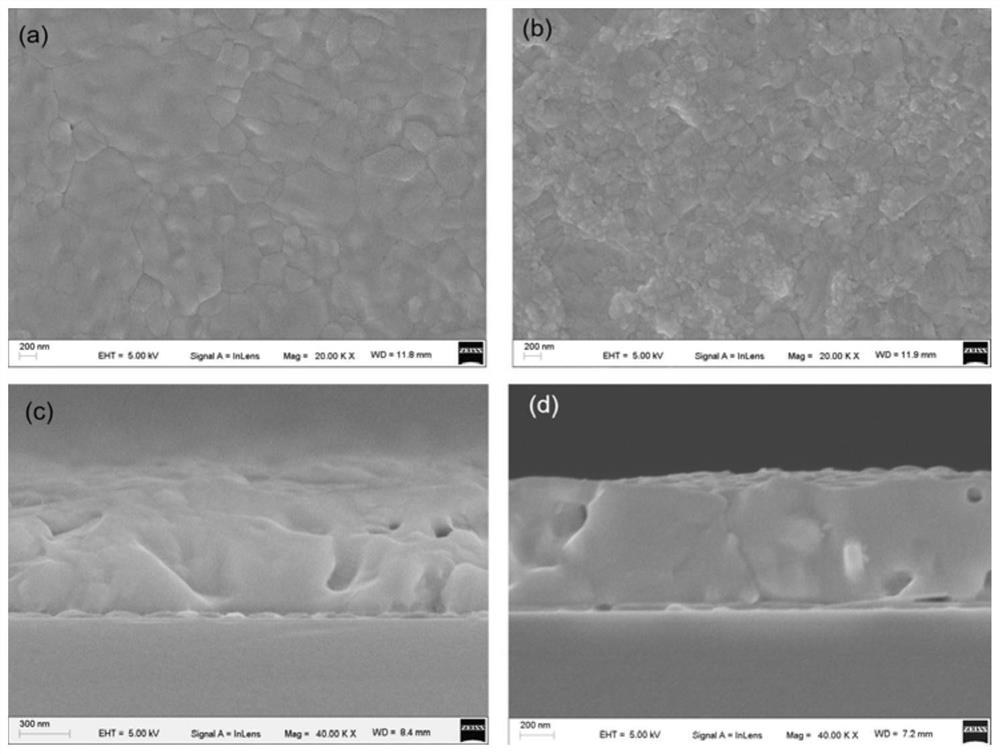

[0042] First, MAPbI prepared on ordinary glass substrates 3 Substrate: PbI 2and MAI were dissolved in DMSO and DMF, the volume ratio was 7:3, the concentration was 1.47M, the anti-solvent was a mixture of toluene and ethyl acetate, the volume ratio was 7:3, the rotation speed was 1000rpm 20s, and 2000rpm 50s, at the end Add the anti-solvent dropwise for 10 seconds, then heat at 60°C for 2 minutes, and continue heating at 100°C for 5 minutes to obtain a perovskite substrate.

[0043] Prepare another layer of perovskite film on the obtained perovskite substrate: get 15mg / mL of MAI (methylamine hydroiodide) solution, the solvent is isopropanol, spin-coat for 30 seconds with the rotating speed of 2000rpm, then take 18mg / mL lead acetate solution, the solvent is acetic acid, spin-coated on the perovskite substrate at a speed of 2000rpm for 30 seconds, and then spin-coated 15mg / mL MAI (methylamine hydroiodide) solution, the solvent is iso propanol, spin-coated at 2000 rpm for 30 s,...

Embodiment 3

[0045] This embodiment provides a FA 1-x MA x PB 3 The preparation method of the perovskite semiconductor material is prepared according to the following steps:

[0046] Get 18mg / mL of lead acetate solution, the solvent is a mixture of acetic acid and ethanol, the ratio is 5 to 5, spin coating with 1000rpm rotating speed for 60 seconds on the PET substrate, spin coating 30mg / mL FAI (a A mixed solution of amidine iodine) and MAI, the solvent is isopropanol, spin-coated at a speed of 1000rpm for 60 seconds, heated at 150°C for 10 minutes to obtain FA 1-x MA x PB 3 perovskite thin film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Short circuit current density | aaaaa | aaaaa |

| Short circuit current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com