Preparation method of nitrogen-phosphorus doped porous carbon for oxygen reduction electrocatalysis in wide pH range

A technology of electrocatalysis and porous carbon materials, which is applied in the preparation/purification of carbon, circuits, electrical components, etc., can solve the problems of insufficient research on oxygen reduction electrocatalysts for fuel cells, and achieve good cycle stability and anti-poisoning performance of impurities. The earth is rich in reserves and the flaky shape is beneficial to the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

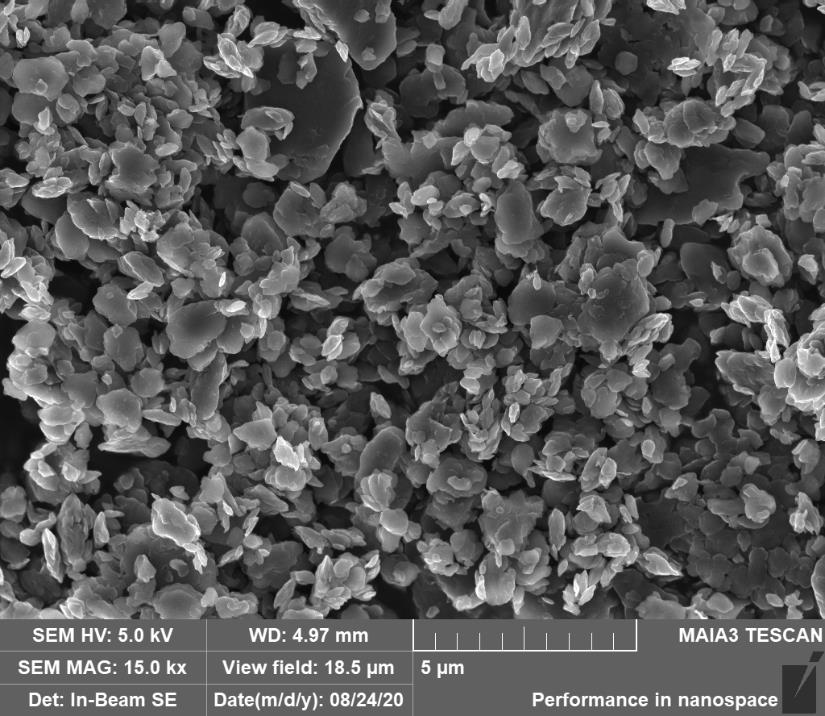

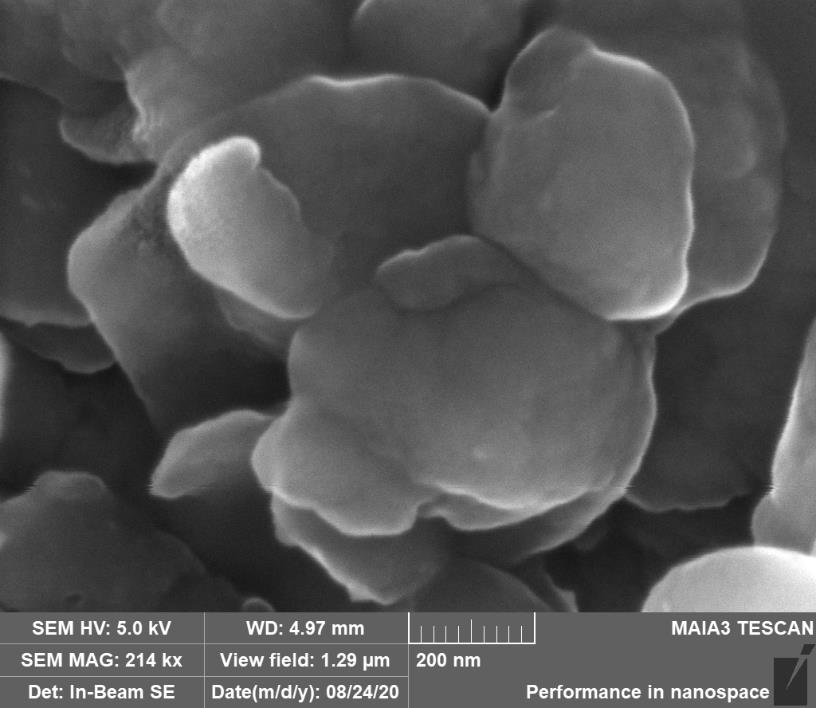

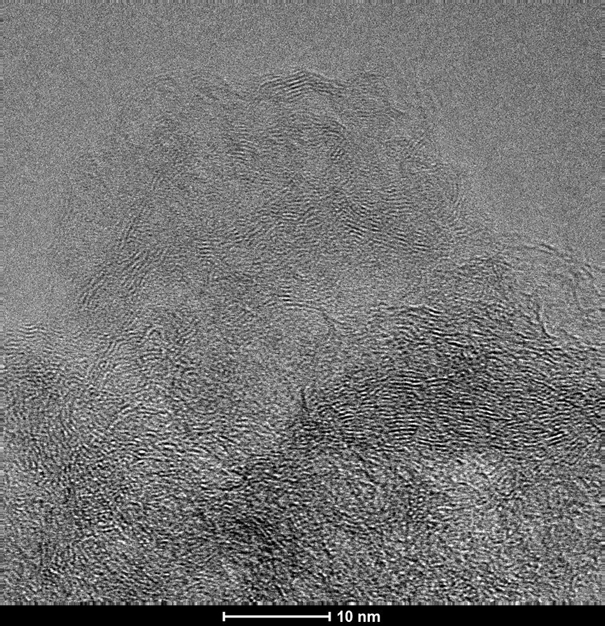

[0059] Respectively, said coal and phosphate after taking pretreatment, diluted with water 4 ultrasonic mixing, particularly ultrasonic parameter is 25 Hz (5 min), 33 Hz (10 min), 40 Hz (5 min), 59 Hz: mass ratio of 1 (10 min), the total time 0.5h, then transferred to a drying tube furnace, min to 3 ℃ under a nitrogen atmosphere –1 Heating rate taken at 900 ℃ carbonized 1 h, after carbonization, the acid, filtered, washed with water, and drying to obtain a carbon-doped phosphorus P 4 C-900; mass ratio of 1: 4: 2 were weighed phosphorous doped carbon, potassium hydroxide and melamine, transferred to a tube furnace after trituration mixing, min to 3 ℃ under a nitrogen atmosphere –1 Heating rate of carbonization at 900 deg.] C 2 h, to give the secondary carbonization product; secondary carbonized product was 1mol L at 40-60 deg.] C –1 Dilute hydrochloric acid solution was 1-3 h, filtered, washed with water until the filtrate was neutral, and dried to obtain a porous carbon material P...

Embodiment 2

[0061] Mass ratio of 1: 4: 2, respectively, after taking said pretreated coal, melamine, potassium hydroxide, mixing after grinding was transferred to a tube furnace, min to 3 ℃ under a nitrogen atmosphere –1 Heating rate, taken after carbonization carbonized at 900 deg.] C 2 h, the acid, filtered, washed with water, and drying to obtain a carbon nitrogen-doped N 4 C-900; mass ratio of 1: 4 Weigh the nitrogen-doped carbon with phosphoric acid, diluted with water ultrasonic mixing, particularly ultrasonic parameter is 25 Hz (5 min), 33 Hz (10 min), 40 Hz (5 min) , 59Hz (10 min), the total time of 0.5 h, after drying was transferred to a tube furnace, min to 3 ℃ under a nitrogen atmosphere –1 Heating rate carbonized at 900 deg.] C 1 h, to give the secondary carbonization product; the second with 1 mol L carbonized product at 40-60 deg.] C –1 Dilute hydrochloric acid solution was 1-3 h, filtered, washed with water until the filtrate was neutral, and dried to obtain a porous carbon ma...

Embodiment 3

[0063] Mass ratio of 1: 4: 2, respectively, after taking said pretreated coal, melamine, potassium hydroxide, mixing after grinding was transferred to a tube furnace, min to 3 ℃ under a nitrogen atmosphere –1 Heating rate, taken after carbonization carbonized at 900 deg.] C 2 h, the acid, filtered, washed with water, and drying to obtain a carbon nitrogen-doped N 4 C-900; mass ratio of 1: 4 were weighed directly after mixing the nitrogen-doped carbon with phosphoric acid was transferred to a drying tube furnace, min to 3 ℃ under a nitrogen atmosphere –1 Heating rate carbonized at 900 deg.] C 1 h, to give the secondary carbonization product; the second with 1 mol L carbonized product at 40-60 deg.] C –1 Dilute hydrochloric acid solution was 1-3 h, filtered, washed with water until the filtrate was neutral, and dried to obtain a porous carbon material Phosphorus doped N 4 P 4 C-900-d.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com