Active clamp flyback converter, controller and control method thereof

A technology of flyback converter and control method, which is applied in the direction of control/regulation system, conversion of DC power input to DC power output, instruments, etc., can solve the problems of large no-load power consumption and low efficiency, and achieve the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

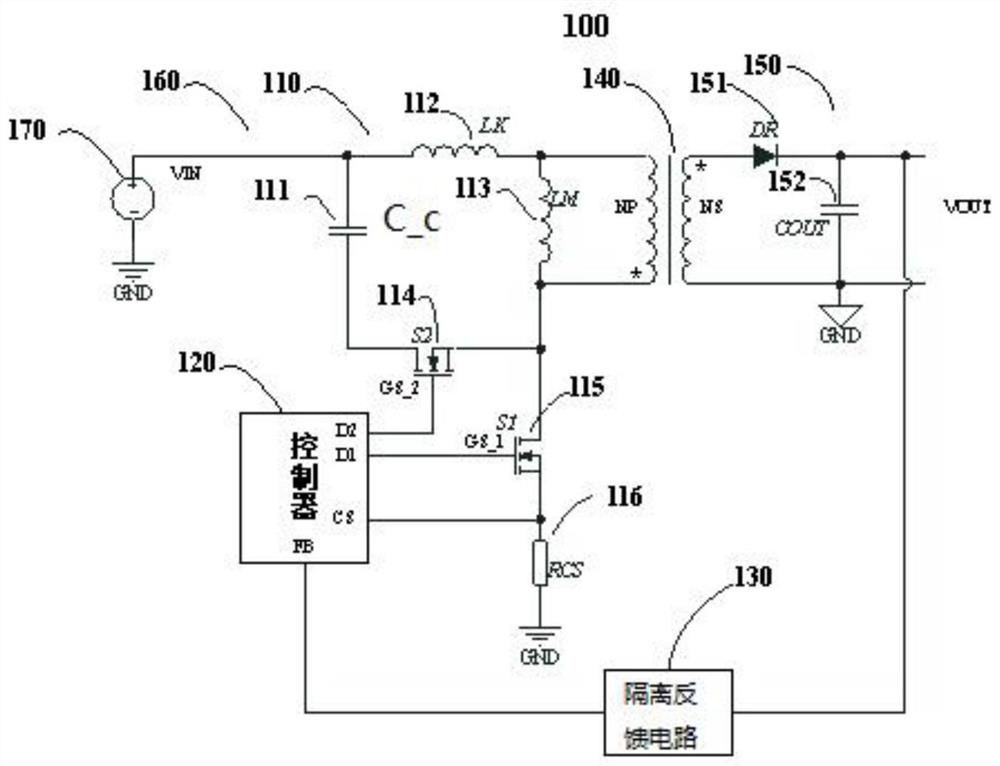

[0054] Please refer to figure 2 , figure 2 It is a schematic diagram of the active clamp flyback converter of the first embodiment of the present invention, the active clamp flyback converter 700 (hereinafter referred to as the converter) is used to convert the input voltage into an output voltage for use by the load , which includes: a transformer, a primary circuit, a secondary circuit, a controller 710 and an isolated feedback circuit 720 .

[0055] The primary winding NP of the transformer is connected to the primary circuit, and the secondary winding NS of the transformer is connected to the secondary circuit.

[0056] The primary side circuit is composed of leakage inductance LK, excitation inductance LM, clamp capacitor C_c, main switch S1, clamp switch S2, excitation inductance LM and current sampling resistor RCS. In this embodiment, the main switch tube S1 and the clamp switch tube S2 are respectively MOS tubes, the drain of the clamp switch S2 is connected to on...

no. 2 example

[0088] Please refer to Figure 9 , Figure 9 It is a schematic circuit diagram of an active clamp flyback converter according to the second embodiment of the present invention. Compared with Embodiment 1, in the embodiment, a resistor Rbleed is connected in parallel to both ends of the clamp capacitor C_c. Since this embodiment The clamp switch S2 is not driven at light load, that is to say, at light no-load, the converter 700 works in the flyback mode, but no matter what mode it works in, the energy on the leakage inductance LK always exists. Therefore, the leakage inductance LK energy will charge the clamping capacitor C_c through the body diode of the clamping switch S2. If the resistor Rbleed is not connected in parallel with the clamping capacitor C_c, the energy on the clamping capacitor C_c will accumulate. When the accumulation reaches a certain level The energy of the leakage inductance LK cannot be charged in, which will cause the converter 700 to work abnormally. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com