Marine product preservative with antibacterial peptide loaded on gliadin nanoparticles and preparation method thereof

A technology of gliadin and nanoparticles, which is applied in the direction of antimicrobial preservation of food ingredients, food preservation, plant protein processing, etc., which can solve environmental pollution, fresh-keeping methods and preservatives that cannot be satisfied by people, improper packaging, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

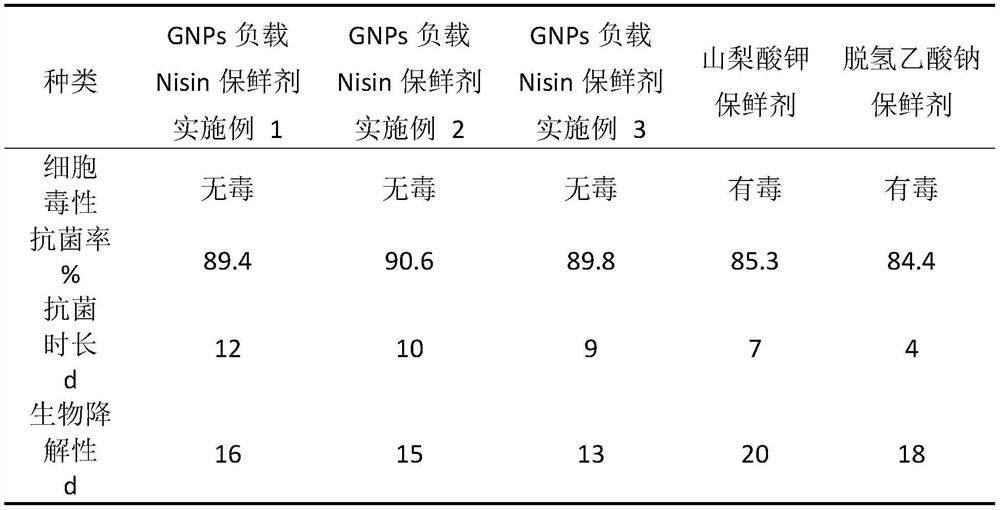

[0020] The invention provides a preparation method of a seafood antistaling agent loaded with antimicrobial peptides on gliadin nanoparticles, which comprises the following steps:

[0021] (1) Extraction of gliadin: take 10 parts of wheat area and dissolve in 100mL ethanol solution of 70% (v / v), stir at 35°C for 5h, collect the supernatant after centrifugation for 15 minutes, and extract the obtained The supernatant is subjected to rotary evaporation and freeze-drying to obtain gliadin powder;

[0022] (2) Preparation of gliadin-Nisin nanoparticles: 3-5 parts of gliadin powder obtained in step (1) and 0.05 part of Nisin were dissolved in 70% (v / v) 100mL ethanol solution in 25°C, stirred for 2h, took 20mL of the mixed liquid and added it dropwise to 100mL distilled water, stirred at 25°C for 3h, after rotary evaporation and centrifugation, the obtained gliadin-Nisin nanoparticle solution was placed in Store at 4°C for later use;

[0023] (3) Preparation of ChNW solution: Diss...

Embodiment 1

[0028] A preparation method for seafood preservatives loaded with antimicrobial peptides on gliadin nanoparticles, comprising the following steps:

[0029] (1) Extraction of gliadin: Take 10 portions of wheat area and dissolve them in 70% (v / v) 100mL ethanol solution, stir at 400r / min for 5h at 35°C, and spin in a centrifuge at 3000rpm , centrifuged for 15 min, and collected the supernatant. The solution was put into a rotary evaporator to remove the alcohol in the solution, and evaporated at -0.1Pa for 20min at 55°C. Finally, the sample was frozen at -80°C for 12 hours, and then freeze-dried for 48 hours to obtain gliadin powder;

[0030] (2) Preparation of gliadin-Nisin nanoparticles: 4 parts of gliadin and 0.05 part of Nisin were dissolved in 100 mL of ethanol solution of 70% (v / v), at 25° C., with magnetic stirring Stir at a speed of 400r / min for 2h; take 20mL of the original solution and drop it in 100mL of distilled water at a speed of 8mL / h, and stir for 3h at a speed...

Embodiment 2

[0034] (1) Extraction of gliadin: Take 10 portions of wheat area and dissolve them in 70% (v / v) 100mL ethanol solution, stir at 400r / min for 5h at 35°C, and spin in a centrifuge at 3000rpm , centrifuged for 15 min, and collected the supernatant. The solution was put into a rotary evaporator to remove the alcohol in the solution, and evaporated at -0.1Pa for 20min at 55°C. Finally, the sample was frozen at -80°C for 12 hours, and then freeze-dried for 48 hours to obtain gliadin powder;

[0035] (2) Preparation of gliadin-Nisin nanoparticles: 3 parts of gliadin and 0.05 part of Nisin were dissolved in 100 mL of ethanol solution of 70% (v / v), at 25° C., with magnetic stirring Stir at a speed of 400r / min for 2h; take 20mL of the original solution and drop it in 100mL of distilled water at a speed of 8mL / h, and stir for 3h at a speed of 400r / min at 25°C; put the solution in a rotary evaporator for 55 °C, -0.1Pa conditions, rotary evaporation for 20min to remove the alcohol in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com