Novel high-thermoplasticity PP super-thick plate and processing method thereof

A high thermal and plastic technology, applied in the direction of chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems of easy deformation, heavy weight and poor strength of PP sheet, and achieve light weight, not easy to layer and break , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

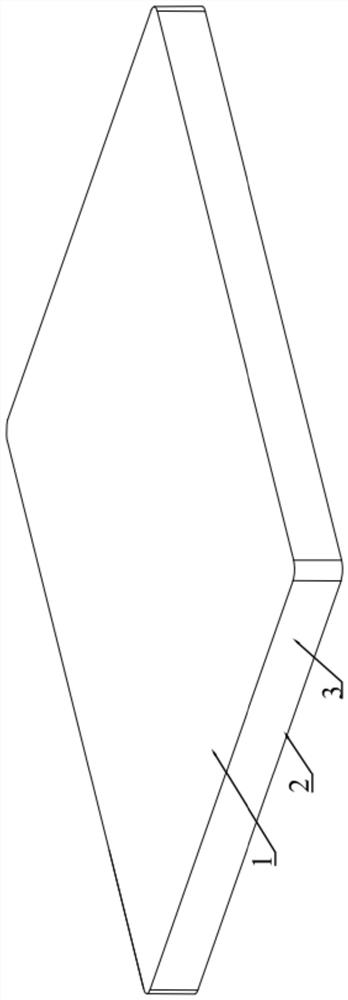

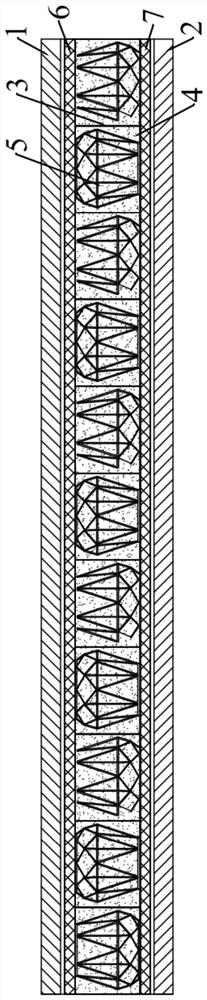

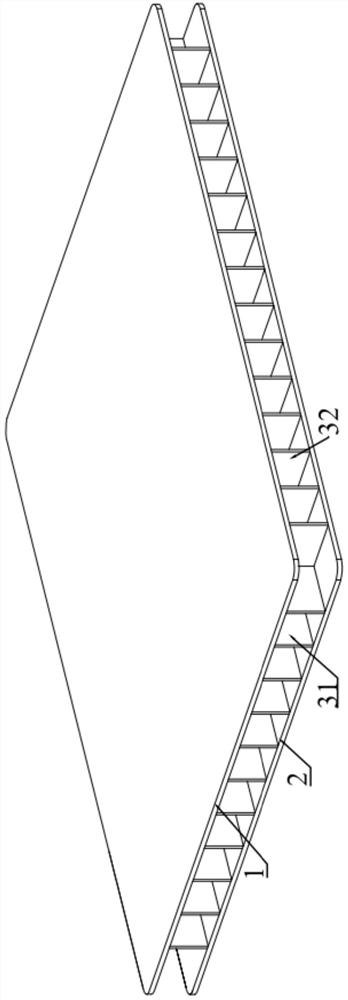

[0062] Such as figure 1 , 2 The new high-thermoplastic PP ultra-thick sheet shown includes a carbon fiber-reinforced epoxy resin composite upper skin 1, a carbon fiber-reinforced epoxy resin composite lower skin 2, PP honeycomb panels 3, a set of epoxy resin foam 4, a Set of epoxy resin foam reinforced bracket 5, upper epoxy resin film 6 and lower epoxy resin film 7, the carbon fiber reinforced epoxy resin composite material upper skin 1 and carbon fiber reinforced epoxy resin composite material lower skin 2 The cross-sectional area of the carbon fiber reinforced epoxy resin composite material is the same, and the upper skin 1 of the carbon fiber reinforced epoxy resin composite material and the lower skin 2 of the carbon fiber reinforced epoxy resin composite material are set oppositely. Between the skin 1 and the lower skin 2 of the carbon fiber reinforced epoxy resin composite material, the set of epoxy resin foam 4 and the set of epoxy resin foam reinforcing brackets 5 ...

Embodiment 2

[0103] The above-mentioned epoxy resin foam 4 includes a foaming epoxy resin and a curing agent, and the foaming epoxy resin includes an epoxy resin, a chemical foaming agent and a nano toughening agent.

[0104] Wherein, the epoxy resin includes E-51 bisphenol A type epoxy resin, nano calcium carbonate, 4,4,-diaminodiphenylmethane, 2-phenylimidazole and acetone, and the E-51 bisphenol Type A epoxy resin, nano-calcium carbonate, 4,4,-diaminodiphenylmethane, 2-phenylimidazole and acetone are calculated in parts by weight:

[0105] E-51 bisphenol A type epoxy resin 110 parts

[0106] Nano calcium carbonate 6 parts

[0107] 4,4,- 60 parts of diaminodiphenylmethane

[0108] 0.6 parts of 2-phenylimidazole

[0109] Acetone 40 parts.

[0110] In addition, chemical foaming agents include sodium dodecylbenzenesulfonate, benzenesulfonyl hydrazide, talc, azodicarbonamide, trifluoropropylene, rosin resin, sodium bicarbonate, deodorant, clay powder, calcium carbonate , sodium dodecyls...

Embodiment 3

[0141] The above-mentioned epoxy resin foam 4 includes a foaming epoxy resin and a curing agent, and the foaming epoxy resin includes an epoxy resin, a chemical foaming agent and a nano toughening agent.

[0142] Wherein, the epoxy resin includes E-51 bisphenol A type epoxy resin, nano calcium carbonate, 4,4,-diaminodiphenylmethane, 2-phenylimidazole and acetone, and the E-51 bisphenol Type A epoxy resin, nano-calcium carbonate, 4,4,-diaminodiphenylmethane, 2-phenylimidazole and acetone are calculated in parts by weight:

[0143] E-51 bisphenol A type epoxy resin 120 parts

[0144] Nano calcium carbonate 8 parts

[0145] 4,4,- 68 parts of diaminodiphenylmethane

[0146] 0.9 parts of 2-phenylimidazole

[0147] Acetone 50 parts.

[0148] In addition, chemical foaming agents include sodium dodecylbenzenesulfonate, benzenesulfonyl hydrazide, talc, azodicarbonamide, trifluoropropylene, rosin resin, sodium bicarbonate, deodorant, clay powder, calcium carbonate , sodium dodecyls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com