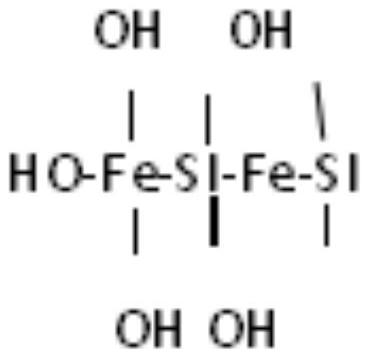

Micron-sized iron-doped silicon dioxide as well as preparation method and application thereof

A silicon dioxide, micron-scale technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, inorganic chemistry, etc., can solve problems such as iron ion precipitation, shutdown and maintenance that cannot be completely solved, and achieve Easy access to raw materials, reduced operating costs, and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] As an example, the preparation method of micron-scale iron-doped silicon dioxide is characterized in that: comprising the following steps:

[0027] S1: Prepare sodium silicate aqueous solution and ferric acetate aqueous solution; the silicon dioxide content of the sodium silicate aqueous solution is 3-5%wt, and the iron oxide content of the ferric acetate aqueous solution is 1-2%wt.

[0028] S2: Add EDTA to the aqueous sodium silicate solution in step S1 at 25-30°C and stir for 20-30 minutes, heat up to 40-50°C and add iron acetate aqueous solution at a rate of 100-200ml / min to pH8-9. The amount of EDTA added is 1-3%wt of silicon dioxide.

[0029] S3: add hydrogen peroxide to the material in step S2 at 80-90° C. and keep it warm for 40-60 minutes.

[0030] The amount of hydrogen peroxide added is 5-10% of the silicon dioxide mass.

[0031] S4: washing the material in step S3 with water until the water resistivity is below 1000Ω / cm.

[0032] S5: Add the materials in s...

Embodiment 1

[0035] S1: Prepare 1000 g of an aqueous sodium silicate solution with a silicon dioxide content of 3%wt, and prepare an aqueous solution of iron oxide with a 2%wt iron oxide content for later use;

[0036] S2: Add 0.9 g of EDTA to the aqueous solution of sodium silicate in step S1 at 25°C and stir for 30 minutes, raise the temperature to 48°C and add iron acetate at a rate of 100ml / min to pH 8.2;

[0037] S3: Warm up the material in step S2 to 80°C, add 3g of hydrogen peroxide and keep it warm for 40 minutes;

[0038] S4: washing the material in step S3 until the water resistivity is below 1000Ω / cm;

[0039] S5: Add the materials in step S4 to the reaction kettle, add water to adjust the carbon dioxide content to 10%, add 0.9g of polycarboxylate water reducer, heat up to 100°C, stir and beat for 40 minutes; stir and keep warm for 2-4 hours.

[0040] S6: Step S5 is dried and pulverized to obtain micron-sized iron-doped silica.

Embodiment 2

[0042] S1: Prepare 1000 g of sodium silicate aqueous solution with a silicon dioxide content of 4%wt, and prepare an aqueous solution of iron oxide with a 1.5%wt iron oxide content for later use;

[0043] S2: Add 0.8 g of EDTA to the aqueous solution of sodium silicate in step S1 at 28°C and stir for 25 minutes, raise the temperature to 40°C and add iron acetate at a rate of 150ml / min to pH 8.5;

[0044] S3: Warm up the material in step S2 to 90°C, add 3.2g of hydrogen peroxide and keep it warm for 50 minutes;

[0045] S4: washing the material in step S3 until the water resistivity is below 1000Ω / cm;

[0046] S5: Add the materials in step S4 to the reactor, add water to adjust the carbon dioxide content to 8%, add 0.8g of polycarboxylate water reducer, heat up to 95°C, stir and beat for 35 minutes; stir and keep warm for 2-4 hours.

[0047] S6: Step S5 is dried and pulverized to obtain micron-sized iron-doped silica.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com