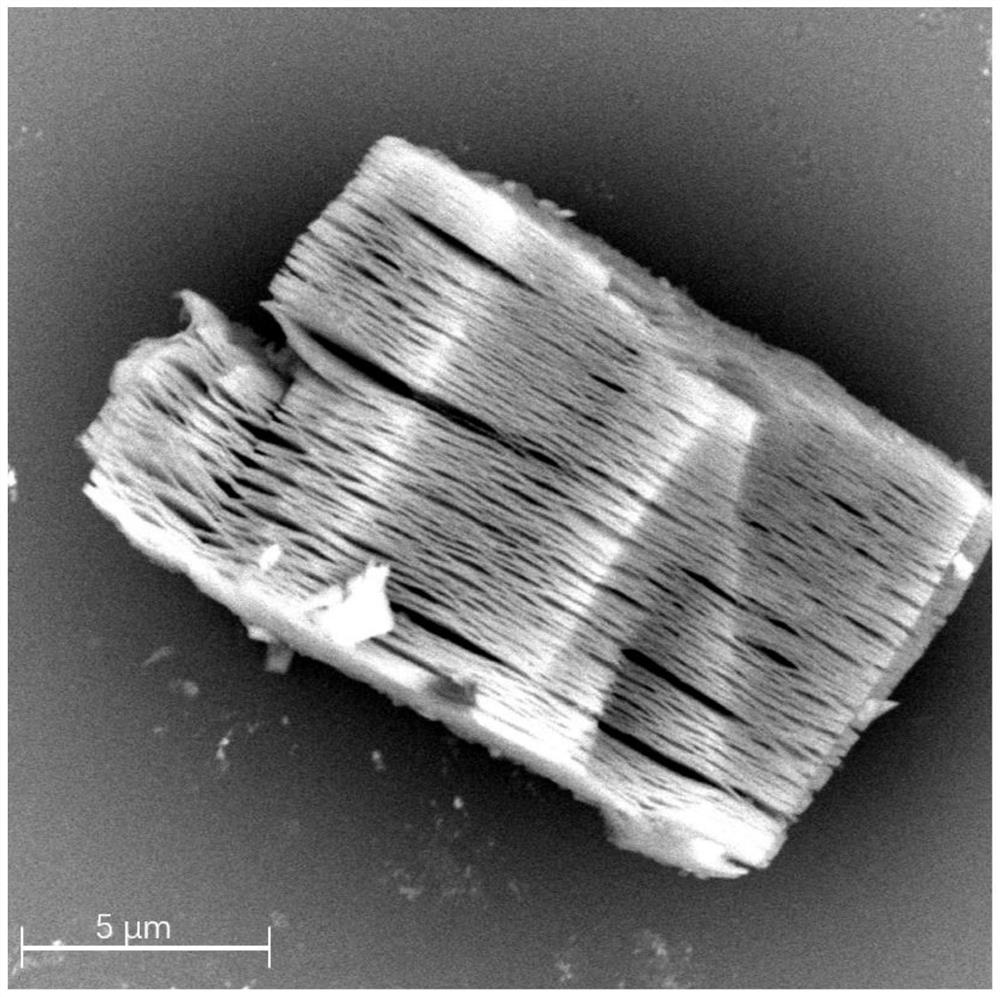

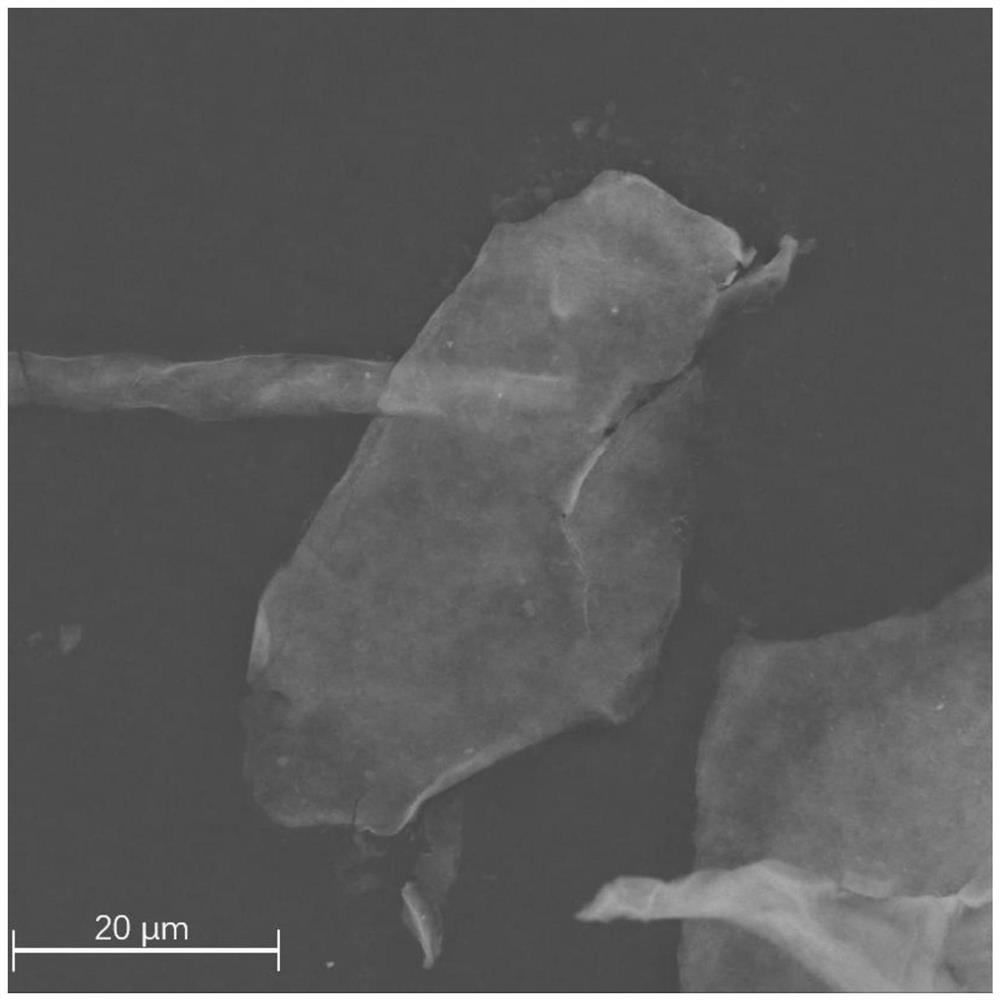

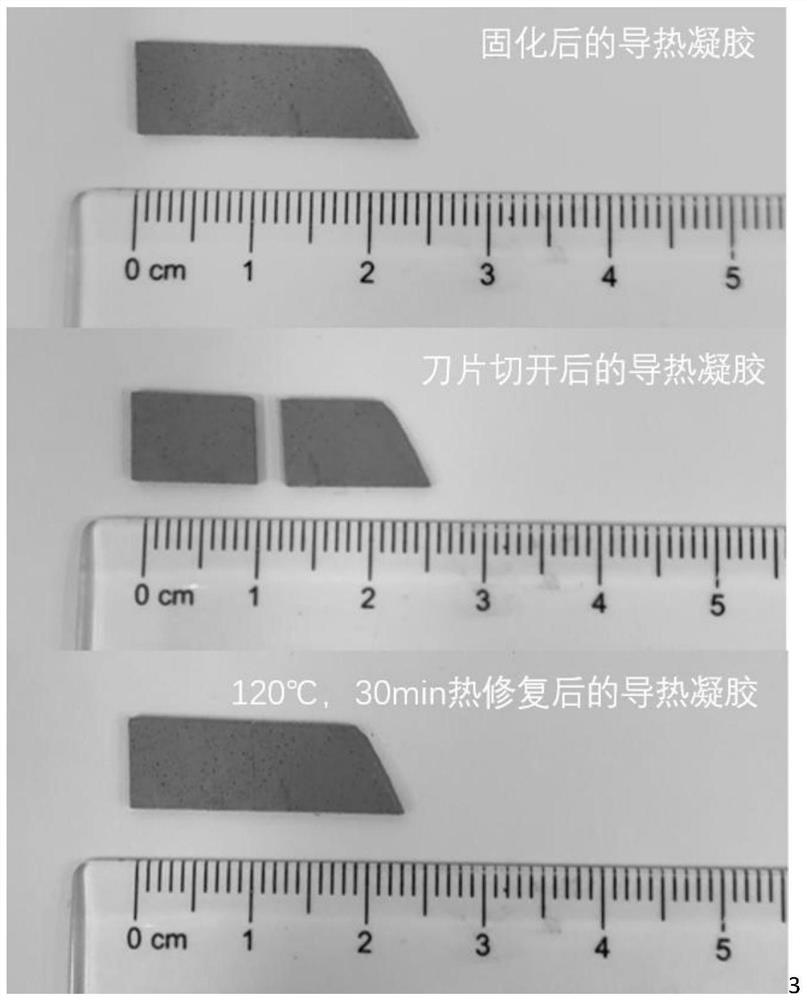

MXene nanosheet compounded thermal conductive gel with thermal self-repairing performance and preparation method of MXene nanosheet compounded thermal conductive gel

A self-healing, nanosheet technology, applied in gel preparation, chemical instruments and methods, colloid chemistry, etc., can solve the problems of decreased interface wettability, reduced service life, large addition amount, etc., to reduce phonon scattering, The effect of improving product reliability and extending the path of heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A thermally conductive gel with thermal self-healing properties composited by MXene nanosheets, comprising the following raw materials in parts by weight:

[0056]

[0057] Wherein, the raw materials for the preparation of the thermal self-healing polymer include the following components by weight:

[0058]

[0059]

[0060] In this embodiment, the chain extender is dimethylhydrogen-terminated polydimethylsiloxane with a hydrogen content of 0.01%-10%;

[0061] In this embodiment, the crosslinking agent is hydrogen-containing branched chain siloxane, and the hydrogen content is 0.01%-10%;

[0062] In this embodiment, the silane coupling agent is aminopropyltrimethoxysilane;

[0063] In this embodiment, the inhibitor is 2-phenyl-3-butyn-2-ol;

[0064] In this embodiment, the catalyst is a chloroplatinic acid catalyst;

[0065] In this embodiment, the conventional thermally conductive filler is spherical alumina; the particle size range of the conventional ther...

Embodiment 2

[0080] A thermally conductive gel with thermal self-healing properties composited by MXene nanosheets, comprising the following raw materials in parts by weight:

[0081]

[0082] Wherein, the raw materials for the preparation of the thermal self-healing polymer include the following components by weight:

[0083]

[0084]

[0085] In this embodiment, the chain extender is dimethylhydrogen-terminated polydimethylsiloxane with a hydrogen content of 0.01%-10%;

[0086] In this embodiment, the crosslinking agent is hydrogen-containing branched chain siloxane, and the hydrogen content is 0.01%-10%;

[0087] In this embodiment, the silane coupling agent is aminopropyltriethoxysilane;

[0088] In this embodiment, the inhibitor is 1-ethynyl-1-1-cyclopentanol;

[0089] In this embodiment, the catalyst is chloroplatinic acid-isopropanol catalyst;

[0090] In this embodiment, the conventional thermally conductive filler is spherical zinc oxide; the particle size range of the...

Embodiment 3

[0105] A thermally conductive gel with thermal self-healing properties composited by MXene nanosheets, comprising the following raw materials in parts by weight:

[0106]

[0107] Wherein, the raw materials for the preparation of the thermal self-healing polymer include the following components by weight:

[0108]

[0109] In this embodiment, the chain extender is dimethylhydrogen-terminated polydimethylsiloxane with a hydrogen content of 0.01%-10%;

[0110] In this embodiment, the crosslinking agent is hydrogen-containing branched chain siloxane, and the hydrogen content is 0.01%-10%;

[0111] In this embodiment, the silane coupling agent is γ-aminopropylaminoethyltrimethoxysilane;

[0112] In this embodiment, the inhibitor is 3-phenyl-1-buten-3-ol;

[0113] In this embodiment, the catalyst is chloroplatinic acid-divinyltetramethyldisiloxane catalyst;

[0114] In this embodiment, the conventional thermally conductive filler is spherical aluminum nitride; the particle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com