Efficient straw enzymolysis method

A straw and enzymatic hydrolysis technology, applied in the biological field, can solve the problems of economic loss, generation of miscellaneous bacteria, affecting the enzymatic hydrolysis effect, etc., and achieve the effects of large economic value, improved accessibility, and high enzymatic hydrolysis effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

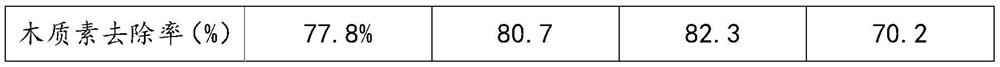

Embodiment 1

[0031] Embodiment 1, a kind of method of efficient enzymolysis straw

[0032] A method for efficient enzymolysis of straw, comprising the following steps:

[0033] S1: Pretreatment of straw:

[0034] 1) After the straw is crushed and passed through a 30-mesh sieve, it is placed in a steamer and steamed for 2 hours to obtain the cooked straw A;

[0035] 2) Add the straw A obtained in step 1) into a mixed solution made of potassium hydrogen persulfate and boric acid, the mass of the mixed solution added is twice the mass of the straw A, and keep it standing for 1 hour at 65° C. Obtain acidified straw B; the preparation method of the mixed solution is: mix potassium persulfate and boric acid according to the mass ratio of 1:1, and dissolve the above-mentioned mixture in deionized water with 5 times the mass, to obtain final product;

[0036] 3) Add the straw B obtained in step 2) to 10 times the mass of deionized water, and keep it at 40°C for 10 minutes to obtain straw C. Dry ...

Embodiment 2

[0038] Embodiment 2, a kind of method of efficient enzymolysis straw

[0039] A method for efficient enzymolysis of straw, comprising the following steps:

[0040] S1: Pretreatment of straw:

[0041] 1) After the straw is crushed and passed through a 30-mesh sieve, it is placed in a steamer and steamed for 3 hours to obtain the cooked straw A;

[0042] 2) Add the straw A obtained in step 1) into a mixed solution made of potassium hydrogen persulfate and boric acid, the mass of the mixed solution added is 3 times the mass of the straw A, and keep it standing for 2 hours at 80° C. Acidified straw B is obtained; the preparation method of the mixed solution is: mix potassium persulfate and boric acid according to a mass ratio of 3:1, and dissolve the above-mentioned mixture in deionized water with 5 times the mass;

[0043] 3) Add the straw B obtained in step 2) to 10 times the mass of deionized water, and keep it at 60°C for 30 minutes to obtain straw C. Dry the straw C in an o...

Embodiment 3

[0045] Embodiment 3, a kind of method of efficient enzymolysis straw

[0046] A method for efficient enzymolysis of straw, comprising the following steps:

[0047] S1: Pretreatment of straw:

[0048] 1) After the straw is crushed and passed through a 30-mesh sieve, it is placed in a steamer and steamed for 2 hours to obtain the cooked straw A;

[0049] 2) Add the straw A obtained in step 1) into a mixed solution made of potassium hydrogen persulfate and boric acid, the mass of the mixed solution added is 3 times the mass of the straw A, and keep it standing for 1 hour at 70° C. Obtain acidified straw B; the preparation method of the mixed solution is: mix potassium persulfate and boric acid according to the mass ratio of 2:1, and dissolve the above-mentioned mixture in deionized water with 5 times the mass;

[0050] 3) Add the straw B obtained in step 2) to 10 times the mass of deionized water, and keep it at 50°C for 20 minutes to obtain straw C. Dry the straw C in an oven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com