Solid Phase Microextraction-High Performance Liquid Chromatography Online Detection Method of Oil Antioxidants

A high-performance liquid chromatography and detection method technology, which is applied in the field of solid-phase microextraction-high performance liquid chromatography on-line detection of oil antioxidants, to achieve the effects of reducing adsorption, reducing impact, and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The covalent organic framework functionalized solid-phase microextraction monolithic column is prepared by mixing covalent organic framework nano-microspheres, urea aqueous solution, formaldehyde aqueous solution and a catalyst, wherein the covalent organic framework nano-microspheres, urea aqueous solution, and formaldehyde aqueous solution , The mass ratio of the catalyst is 2:9:11:2.

[0028] The aqueous urea solution has a concentration of 1 g / mL; the aqueous formaldehyde solution has a mass concentration of formaldehyde of 37%; the catalyst is an aqueous hydrochloric acid solution with a concentration of 0.1 mol / L.

[0029] The preparation method of the covalent organic framework functionalized solid-phase microextraction monolithic column comprises the following steps:

[0030] (1) Cleaning the empty tube: Rinse the empty PTFE tube with chromatographically pure methanol, then dry it in an oven at 60°C until use; the PTFE tube used is 10 cm in length and 750 mm in ...

Embodiment 2

[0035] The specific operation steps of the combined system are as follows:

[0036] In the first step, both the ten-way valve and the six-way valve of the online coupling system are in the LOAD position; the loading liquid passes through the pump A to balance the covalent organic framework functionalized solid-phase microextraction monolithic column (the monolithic column prepared in Example 1), and the flow rate is The flow rate is 0.1 mL / min; the mobile phase passes directly through the analytical column through pump B to obtain a stable baseline required for chromatographic separation, and the flow rate is 1.0 mL / min; at the same time, the sample solution is filled with the 0.5 mL PEEK tube quantitative loop through the injection needle;

[0037] In the second step, the six-way valve is adjusted to the INJECT position, and the online solid-phase microextraction starts. The sample in the 0.5 mL PEEK tube quantitative loop is brought into the covalent organic framework functio...

Embodiment 3

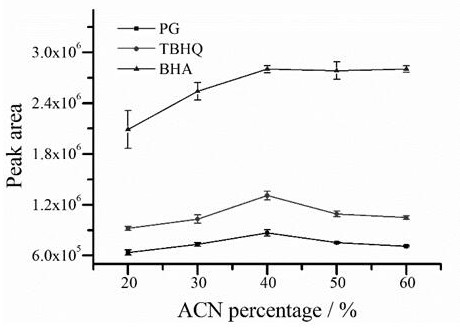

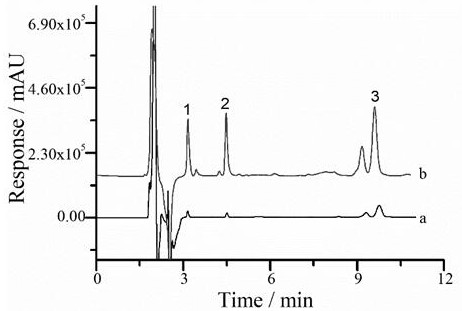

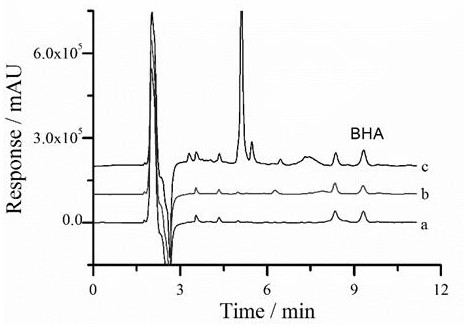

[0042] According to the technical scheme of Example 2, first prepare the covalent organic framework functionalized monolithic column of Example 1, and use the monolithic column as the solid-phase microextraction medium, refer to the relevant patent (patent number: 2018207623454) to construct solid-phase microextraction- High performance liquid chromatography online coupled analysis system. Then, relying on the on-line combined system to enrich and detect the antioxidants in oils, the optimized parameters of the combined system operation are: sample loading solution is ACN / 5 mM pH=6.0 ammonium formate solution=40% / 60% (v / v) ; eluent is acetonitrile; injection flow rate is 0.10 mL / min; elution flow rate is 0.10 mL / min; elution volume is 200 μL (eluate two minutes before collection); mobile phase is ACN / 0.05% formic acid solution= 60% / 40% (v / v); the flow rate of the mobile phase was 1.0 mL / min; the temperature of the column oven was 40 ℃; the detection wavelength was set at 201 n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com