Composite waterproof sealant as well as preparation method and application thereof

A waterproof sealing and composite technology, applied in the direction of adhesive additives, non-polymer adhesive additives, adhesives, etc., can solve the problems of long curing time and low efficiency, and achieve strong impermeability, good bonding strength, The effect of high elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

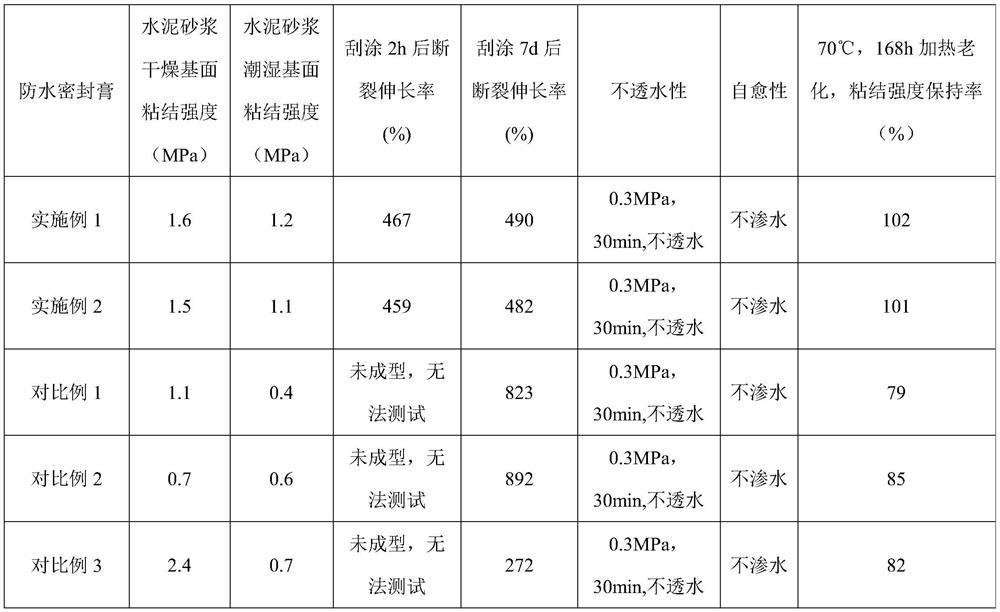

Examples

Embodiment 1

[0042] The composite waterproof sealant of this embodiment is composed of three components A, B, and C, and the mass ratio of A component, B component, and C component is 100:2:1.5; wherein, A component includes the following The composition of parts by mass: 22 parts of unsaturated polyester resin, 4 parts of methyl methacrylate, 33 parts of butyl methacrylate, 5 parts of flexible monomer, 10 parts of nano calcium carbonate, 14 parts of 1250 mesh silicon powder, gas phase two 8 parts of silicon oxide, 3.7 parts of organic bentonite, and 0.3 parts of thixotropic agent; component B includes the following ingredients by mass: 96.6 parts of accelerator, 3.4 parts of pigment; component C includes the following ingredients by mass: 100 parts of initiator.

[0043] The preparation method of the compound type waterproof sealing paste of the present embodiment comprises the following steps:

[0044] (1) Weigh 220g TCD-17 resin, 40g methyl methacrylate, 330g butyl methacrylate, 30g met...

Embodiment 2

[0049] The composite waterproof sealant of this embodiment is composed of three components A, B, and C, and the mass ratio of A component, B component, and C component is 100:2:1.5; wherein, A component includes the following The composition of parts by mass: 20 parts of unsaturated polyester resin, 2 parts of methyl methacrylate, 37 parts of butyl methacrylate, 5 parts of flexible monomer, 10 parts of nano calcium carbonate, 14 parts of 1250 mesh silicon powder, gas phase two 8 parts of silicon oxide, 3.8 parts of organic bentonite, 0.2 parts of thixotropic agent, and 100 parts of initiator; component B includes the following components by mass: 96 parts of accelerator, 4 parts of pigment; component C comprises the following components by mass: 100 parts of initiator.

[0050] The preparation method of the compound type waterproof sealing paste of the present embodiment comprises the following steps:

[0051] (1) Weigh 200g TCD-17 resin, 20g methyl methacrylate, 370g butyl m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com